An automated logistics cultivation seedbed

A technology for moving seedbeds and seedbeds, applied in planting beds, botanical equipment and methods, horticulture, etc., can solve the problems of low degree of mechanization, easy to bring diseases and insect pests, and high labor cost, and achieve a high degree of liberalization and easy to scale. The effect of cultivation and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

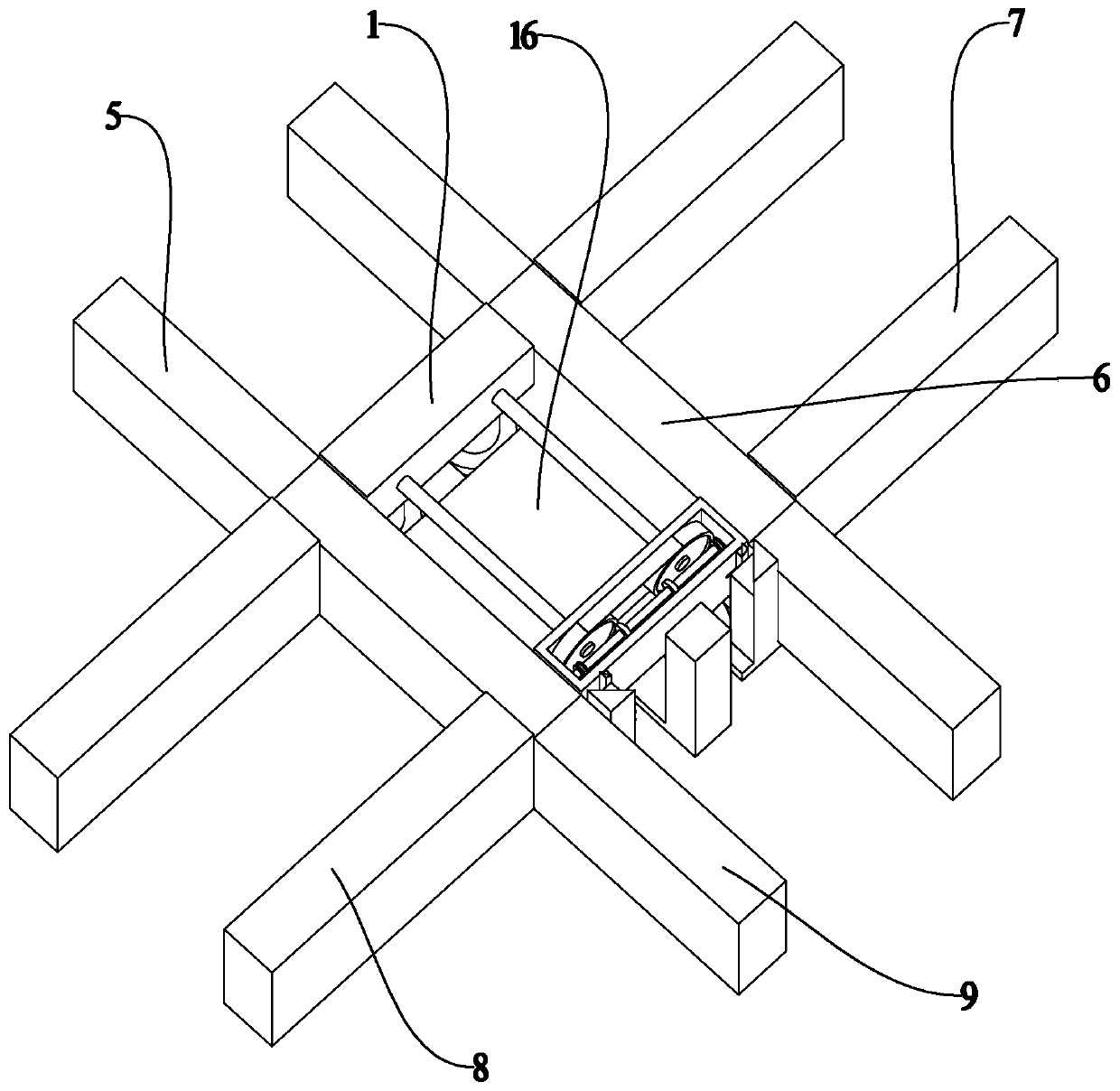

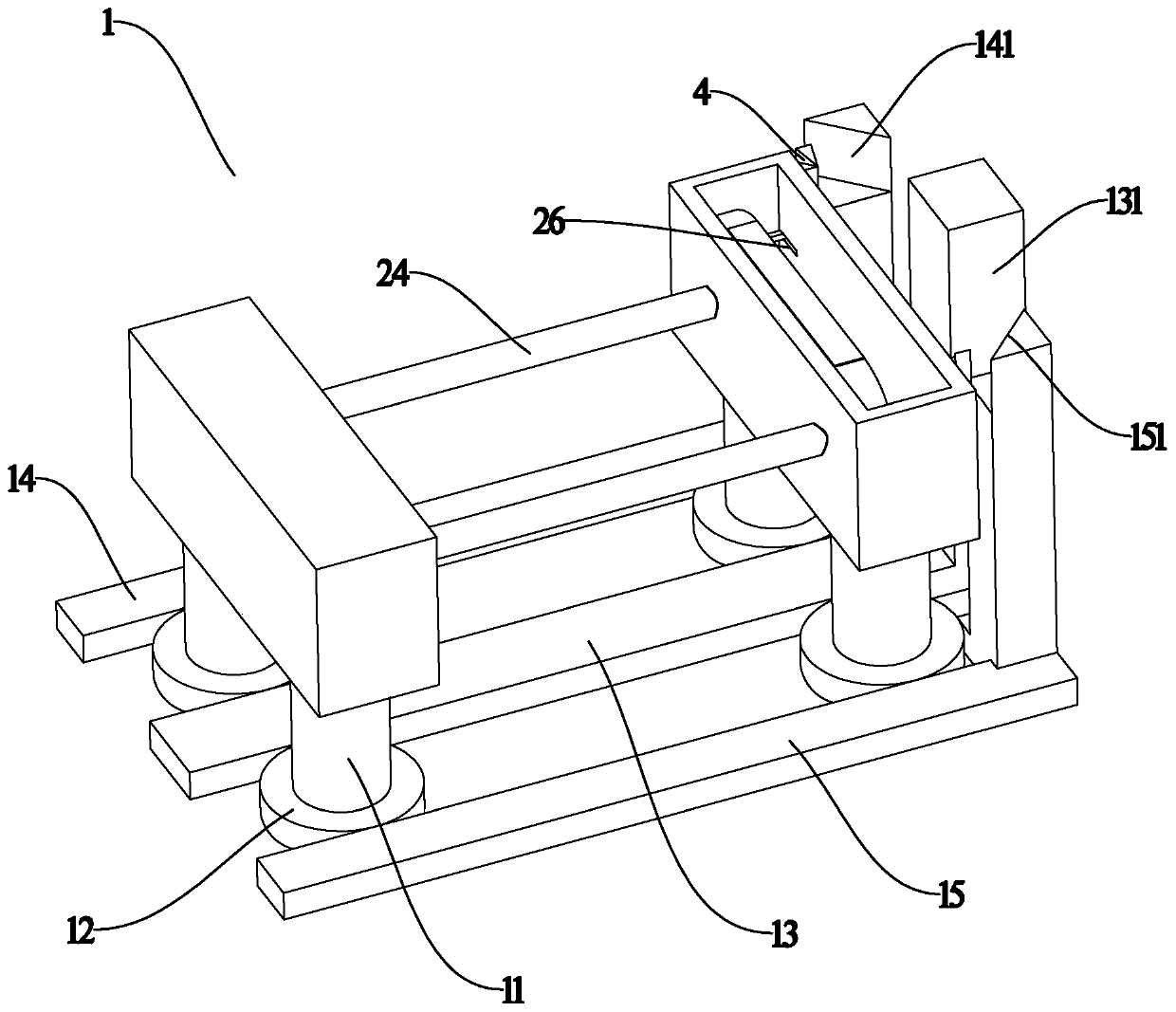

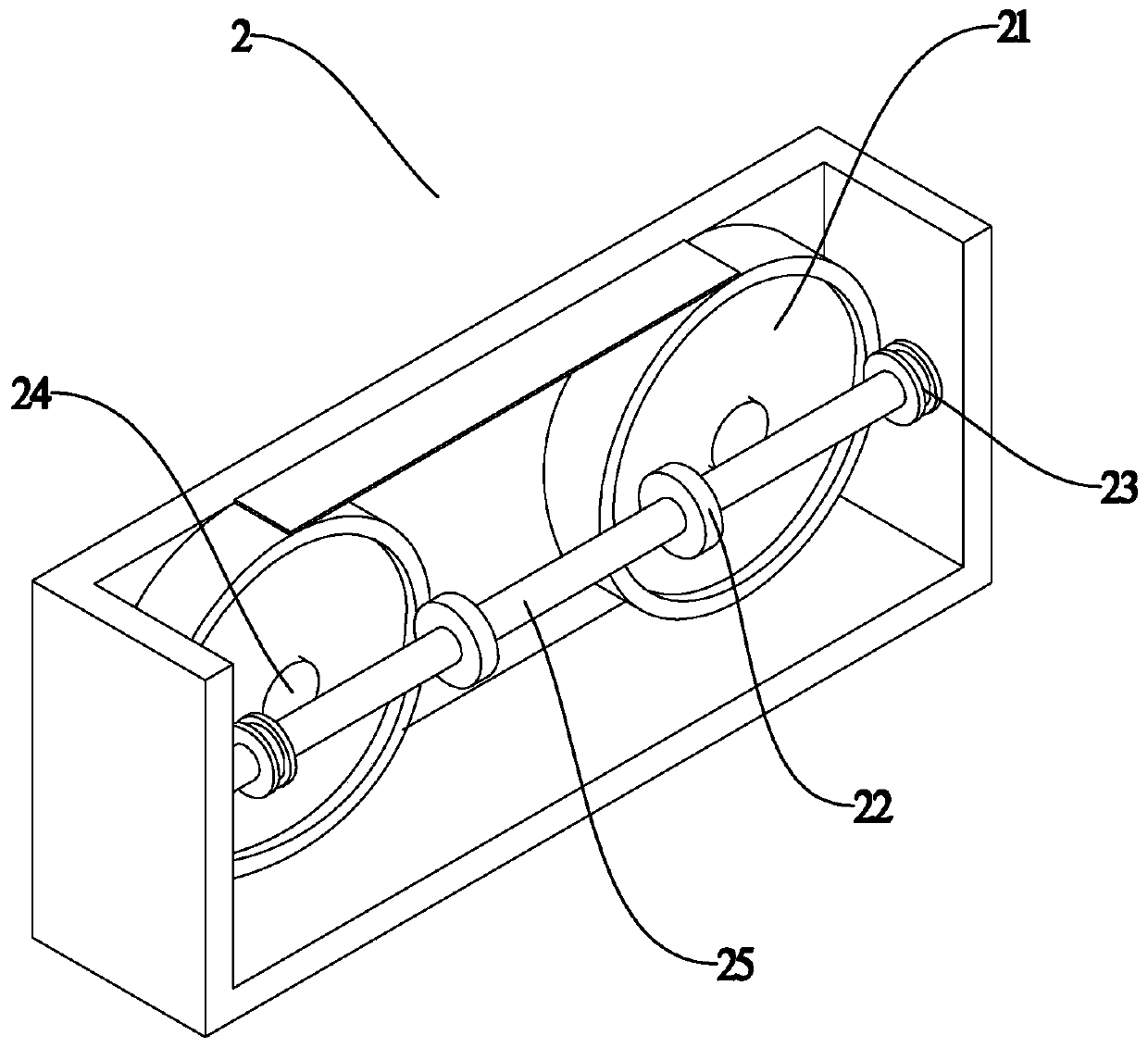

[0026] According to a preferred embodiment of the present invention, it includes a guide rail module and a mobile seedbed 3 matched with the guide rail module, wherein the guide rail module includes an entrance guide rail 5, a transition guide rail 6, a left turn guide rail 7, a right turn guide rail 8, The outlet guide rail 9 and the steering mechanism 1 arranged between the transition guide rails 6, the steering mechanism 1 includes a steering guide rail 2 perpendicular to the advancing direction of the inlet guide rail 5 and four screw rods 11 supporting the steering guide rail 2, The bottom of the screw rod 11 is connected with an internally threaded gear 12 that can control the movement of the screw rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com