Waste gas dust-removal and purification all-in-one machine

An all-in-one machine and exhaust gas technology, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve problems such as high content of harmful substances, environmental pollution, and harm to human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

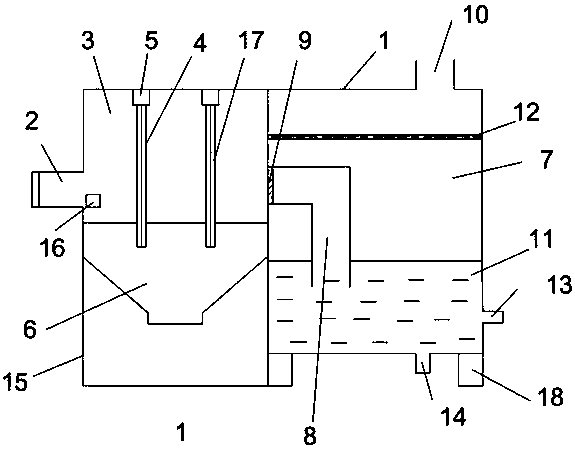

[0014] see figure 1 , the present invention provides a technical solution: an exhaust gas dust removal and purification integrated machine, including a box body 1, an air inlet 2 is arranged on the left side of the box body 1, a filter chamber 3 is arranged inside the box body 1, and the filter chamber 3 Two filter plates 4 are arranged inside the chamber 3, a vibrating motor 5 is installed on the upper part of the filter plate 4, an ash collecting bucket 6 is arranged on the lower part of the filter chamber 3, a clean room 7 is set on the right side of the filter room 3, and the clean room 7 is connected with the filter chamber 3 through an air guide pipe 8, and an odor-proof net 9 is arranged at the entrance of the air guide pipe 8, and an air outlet 10 is arranged on the upper part of the clean room 7, and a purification pool 11 is arranged inside the clean room 7, and the air guide pipe 8 Extending to the inside of the purification pool 11, an activated carbon layer 12 is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap