Two-time demolding mechanism

A secondary demoulding and mold technology, which is applied in the field of molds, can solve problems such as buckle breakage, low yield rate, and buckle deformation, so as to achieve the effect of not easily deforming and improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

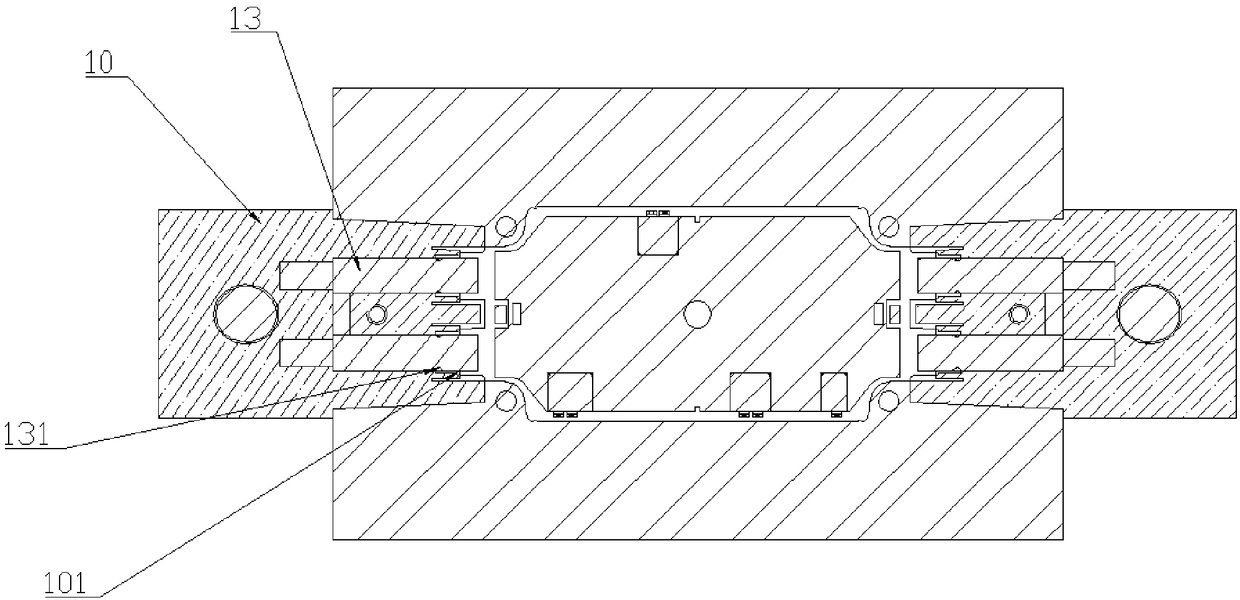

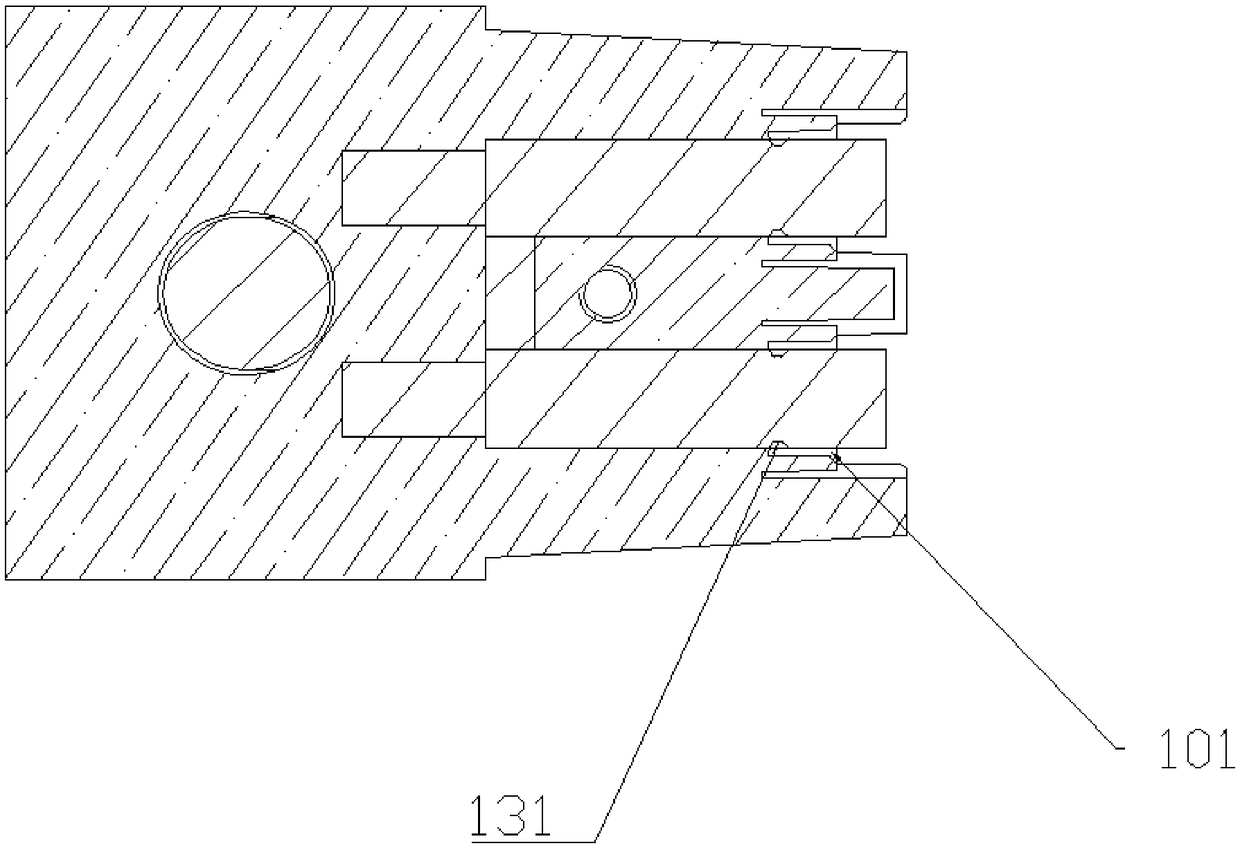

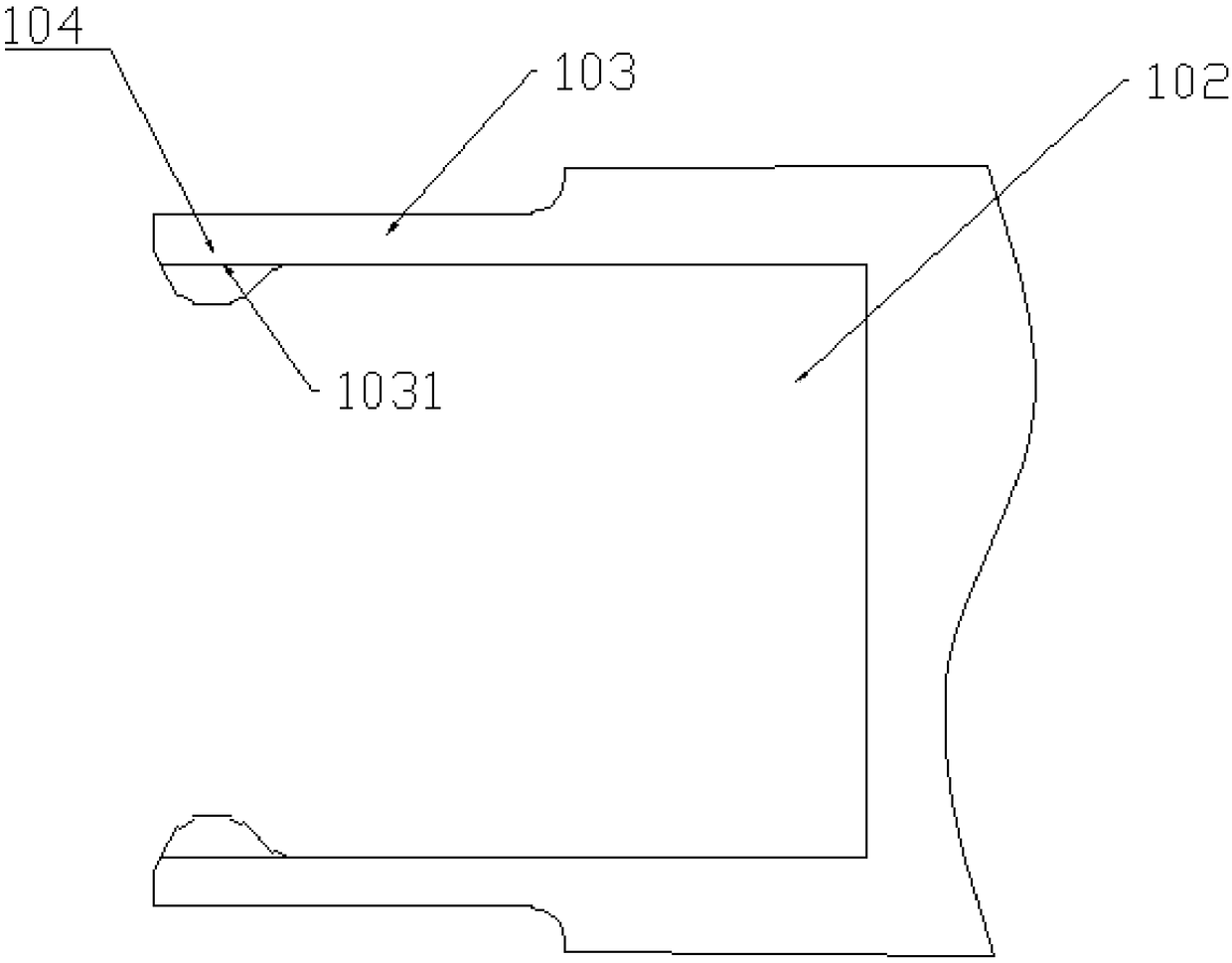

[0023] Such as Figure 1 to Figure 3 As shown, this embodiment introduces the secondary demoulding mechanism by taking the side frame of the IGBT module as an example. Elastic arms 102 are arranged on both sides of the side frame of the IGBT module. Deduction 104. Figure 4 A mold 200 for forming the side frame of the IGBT module is shown, and the secondary demoulding mechanism 100 is arranged on both sides of the mold 200 . When demoulding, the secondary demoulding mechanism 100 can effectively protect the buckle 104 of the product from being strained and deformed. The column body 103 includes a side surface 1031 , the buckle 104 is disposed on the side surface 1031 , and the slider insert 13 includes a mating surface adjoining the side surface 1031 .

[0024] Specifically, such as Figure 5 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com