LCD screen cutting and processing device

A technology of cutting processing and liquid crystal screen, which is applied in the direction of glass cutting devices, manufacturing tools, glass manufacturing equipment, etc., can solve problems such as long service time, loose fixtures, and complicated workpiece fixing structure, and achieve simple structure and increase the processable area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is further described in detail through specific implementation methods:

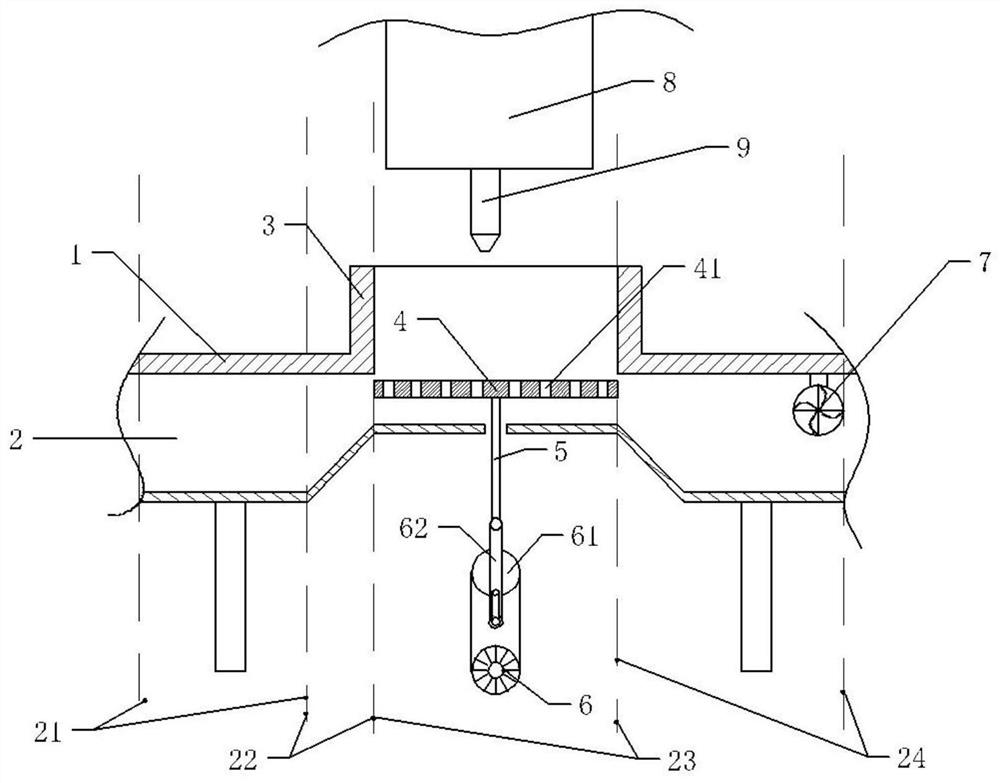

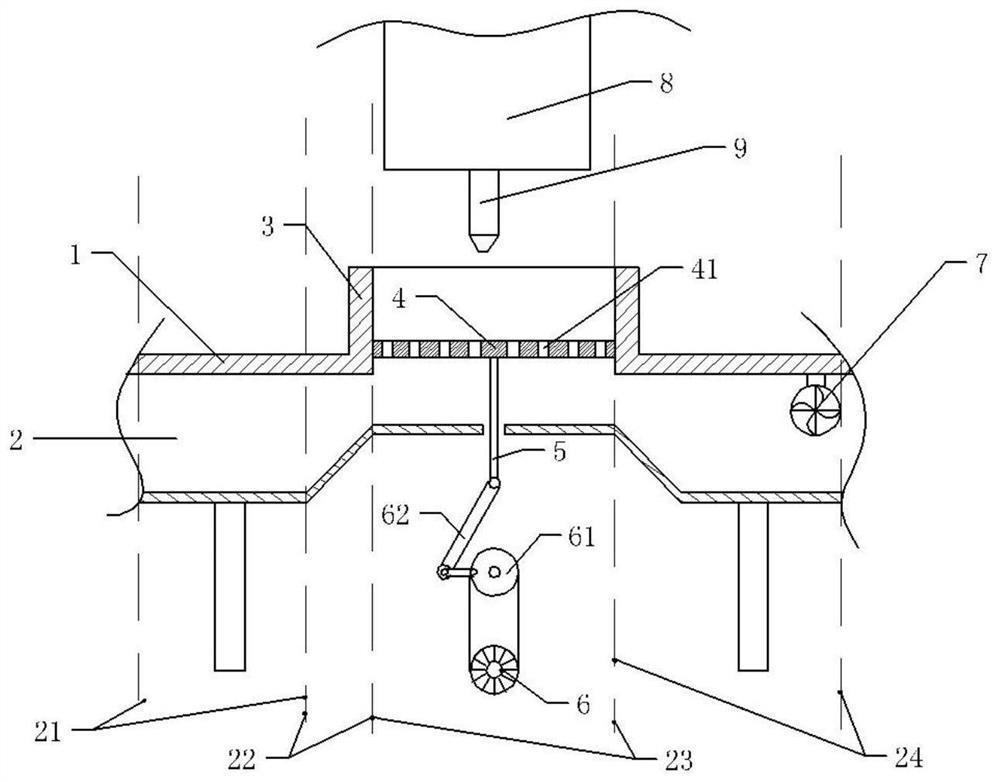

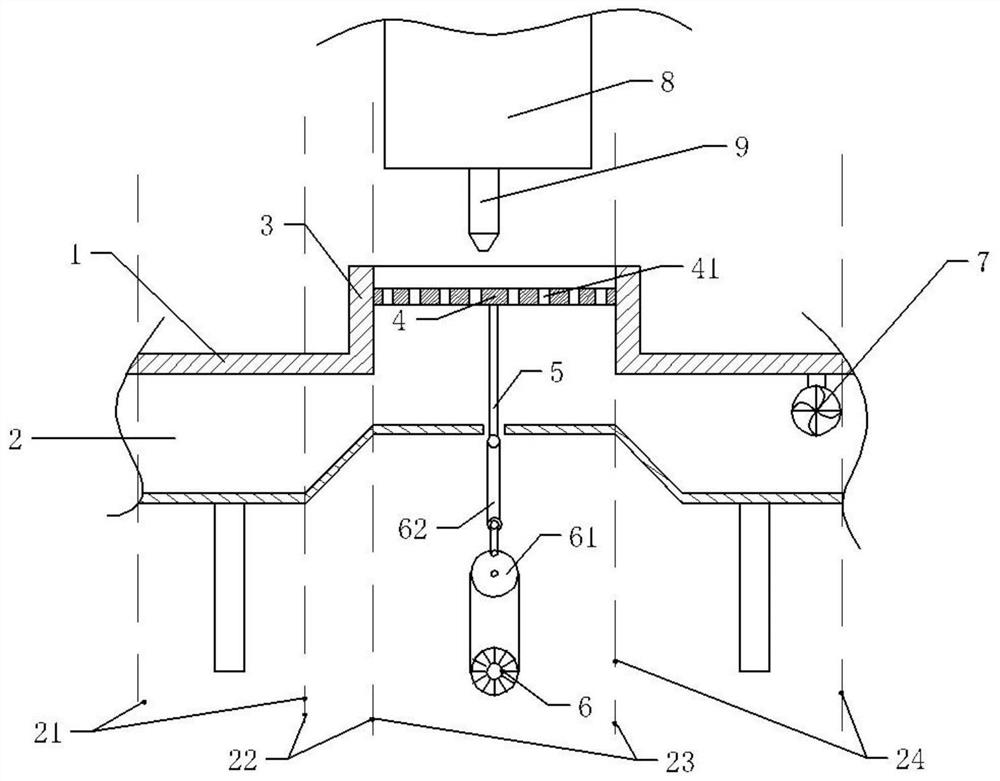

[0021] The reference signs in the drawings of the description include: workbench 1, pipeline 2, inlet section 21, constriction section 22, narrow channel 23, diffusion section 24, boss 3, storage table 4, through hole 41, support rod 5, crank 61, connecting rod 62,, motor 6, blower fan 7, moving frame 8, cutting head 9.

[0022] The embodiment is basically as attached figure 1 Shown:

[0023] A liquid crystal screen cutting and processing device, including a workbench 1, a moving frame 8 and a cutting head 9, and also includes a pipeline 2, which is located under the workbench 1, and the pipeline 2 includes an entrance section 21, a contraction section 22, a narrow channel 23 and a diffusion Section 24, in the diffusion section of the pipeline 2, an exhaust fan 7 is provided, and the workbench 1 is provided with a boss 3, and the boss 3 is provided with a passage extending to the n...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap