A kind of polypropylene odor absorption master batch for automobile and preparation method thereof

A technology of odor adsorption and polypropylene, which is applied in the field of polypropylene odor adsorption masterbatch for automobiles and its preparation, which can solve the problems of reducing odor and achieve the effect of avoiding volatilization and improving odor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with specific examples.

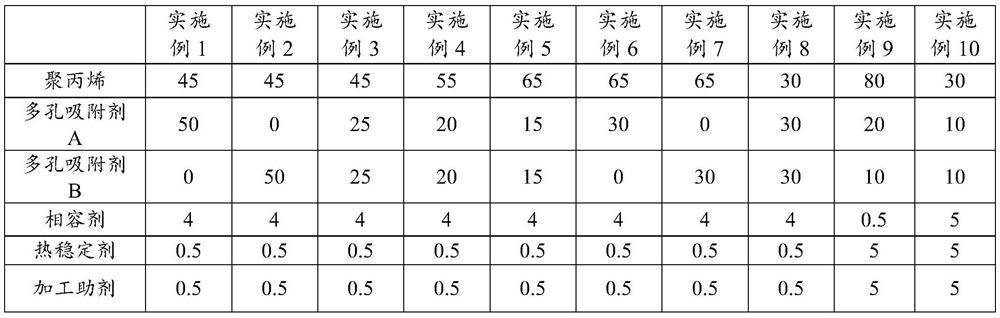

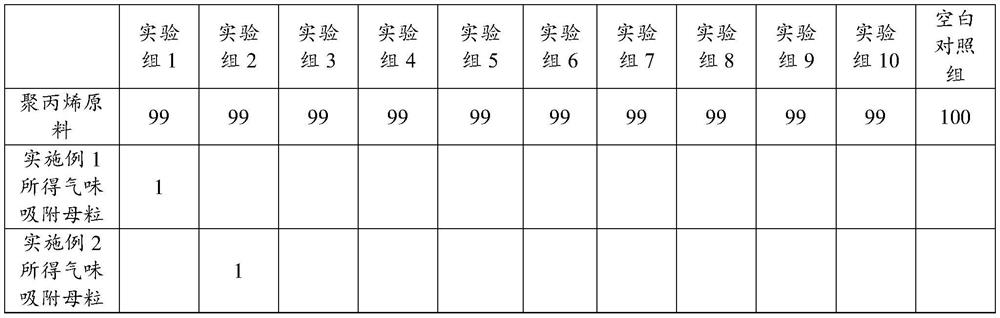

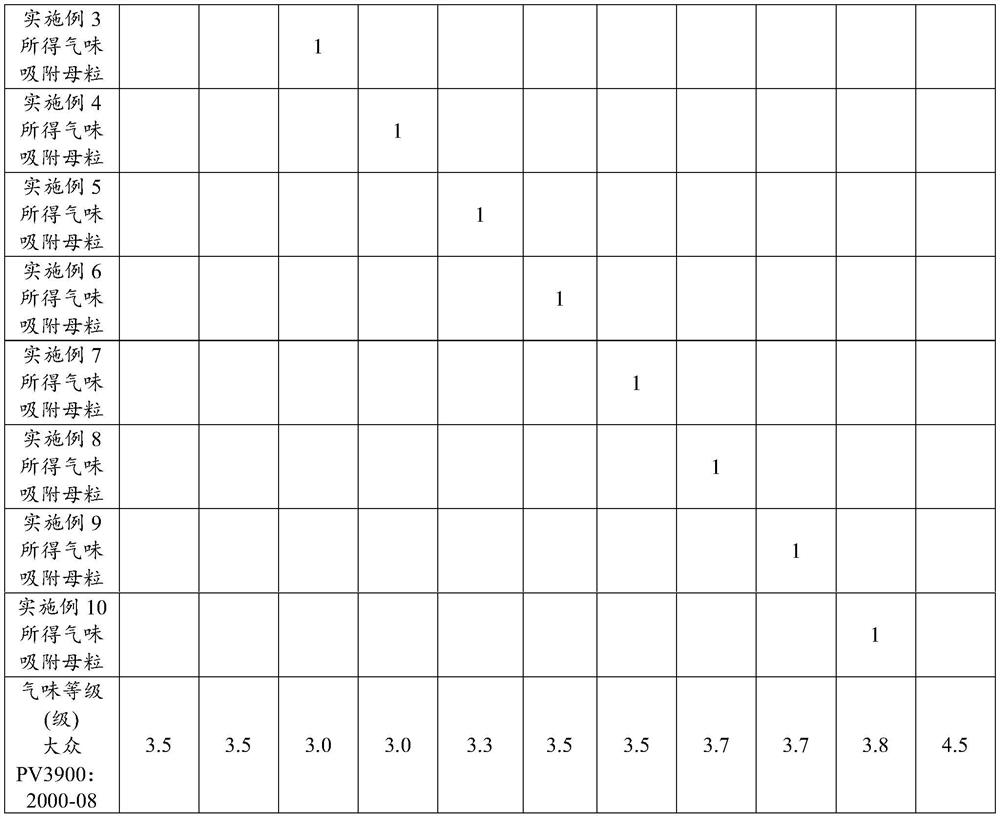

[0021] Ten kinds of embodiments of the polypropylene odor-absorbing masterbatch for automobiles of the present invention, the weight parts of each component of the polypropylene odor-absorbing masterbatch for automobiles described in Examples 1 to 10 are shown in Table 1, wherein the present invention implements In the example, the melt flow index of the polypropylene under the test conditions of 230°C and 2.16kg is 10g / 10min; the porous adsorbent A and the porous adsorbent B are both hydrogen-type aluminosilicate porous molecular sieves; the porous adsorbent Agent A, SiO 2 with Al 2 o 3 The molar ratio is 50:1, the pore volume is 0.96cm 3 / g, the pore size is 6-10nm; in porous adsorbent B, SiO 2 with Al 2 o 3 The molar ratio is 500:1, the pore volume is 0.96cm 3 / g, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com