A folding test mechanism and working method

A technology of folding resistance and test position, which is applied in the direction of applying stable bending force to test the strength of materials, instruments, measuring devices, etc. It can solve the problems of low precision, unsatisfactory effect, and weak clamping force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

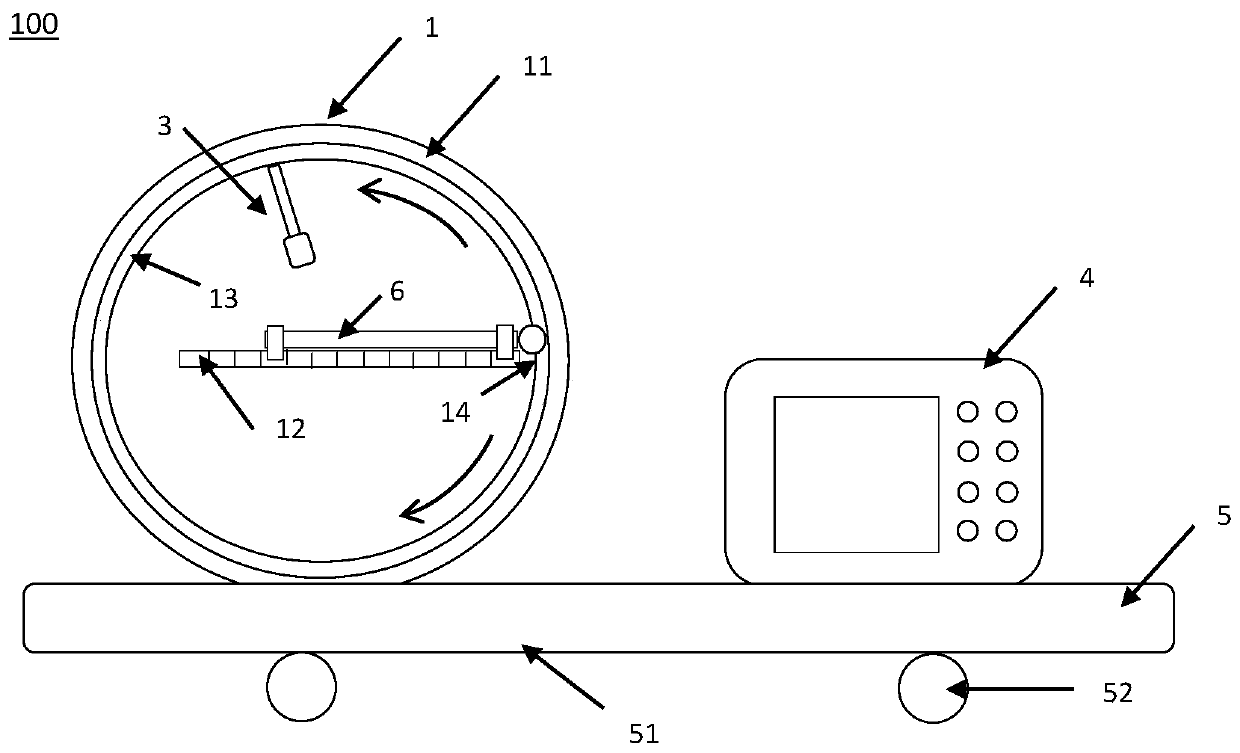

[0044] Folding test mechanism 100 of the present invention such as Figure 1 to Figure 8 As shown, it includes the bending part 1, the transmission part 2, the detection part 3, the control part 4 and the support part 5, the bending part 1 and the control part 4 are fixed on the support part 5, and the transmission part 2 is fixed on the bending part 1 superior.

[0045] Such as figure 1 As shown, the bending part 1 includes a circular support frame 11, a loading platform 12 fixed inside the support frame 11, a slide rail 13 located inside the support frame 11, and a guide 14 installed on the slide rail 13. The guide 14 can move clockwise or counterclockwise on the supporting frame 11, one end of the loading platform 12 is fixed on the guide 14, the other end of the loading platform 12 is fixed on the supporting frame 11, and the specimen 6 is fixed on the loading platform 12 superior.

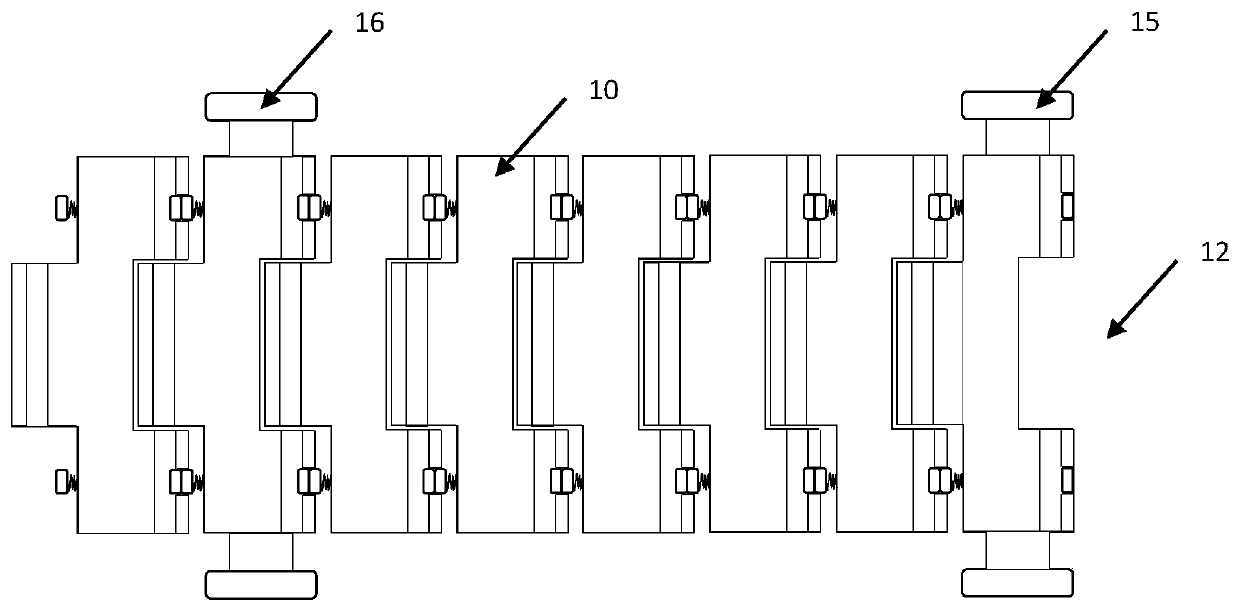

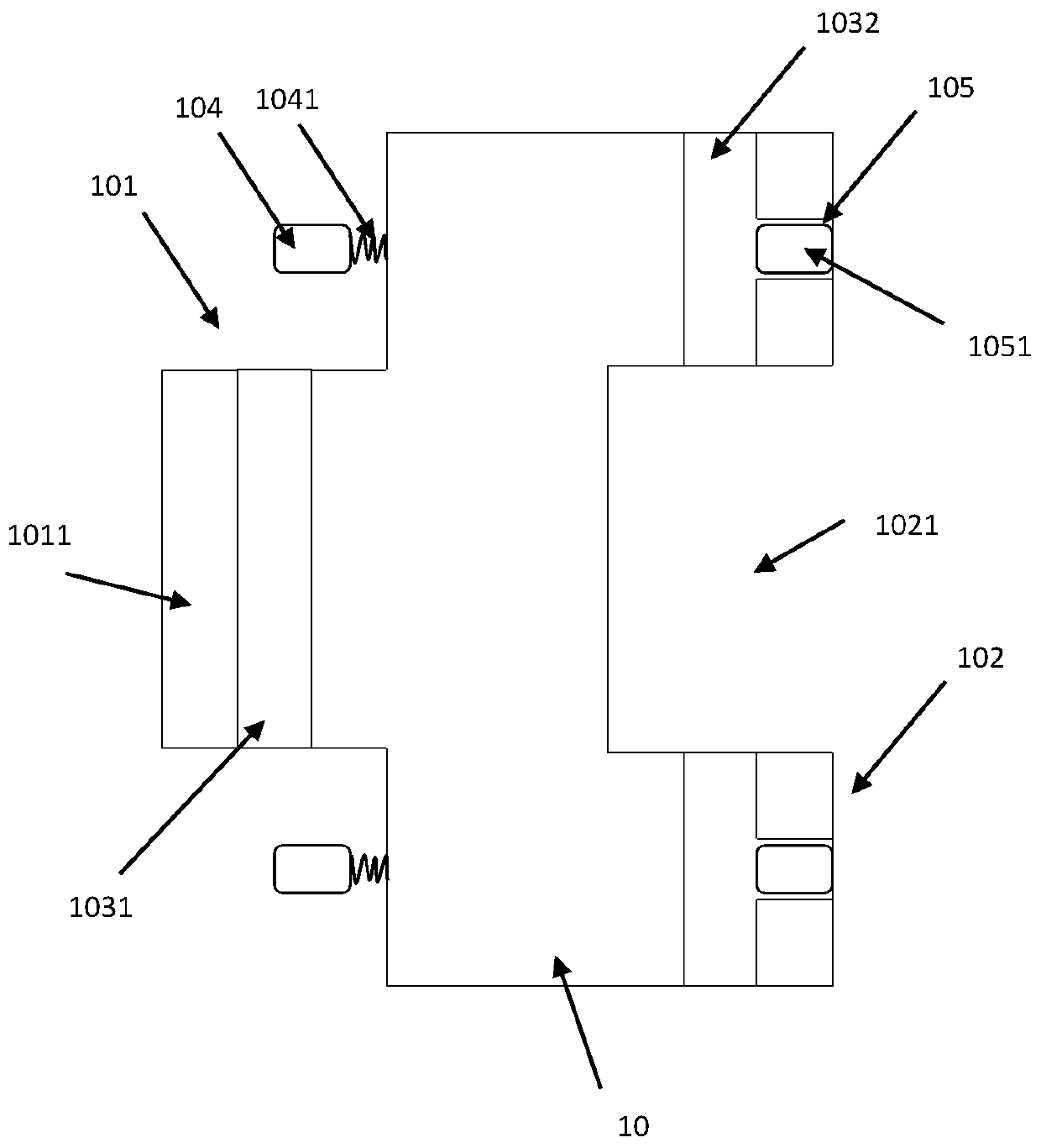

[0046] Specifically, such as figure 2 As shown, the loading platform 12 also includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com