A self-circulating cleaning food processing machine

A technology for food processing machines and cup lids, which is applied to household appliances, applications, kitchen utensils, etc., can solve the problem that the area is difficult to be effectively washed, and achieve good cleaning effect, ensure cleaning effect, and improve the effect of cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

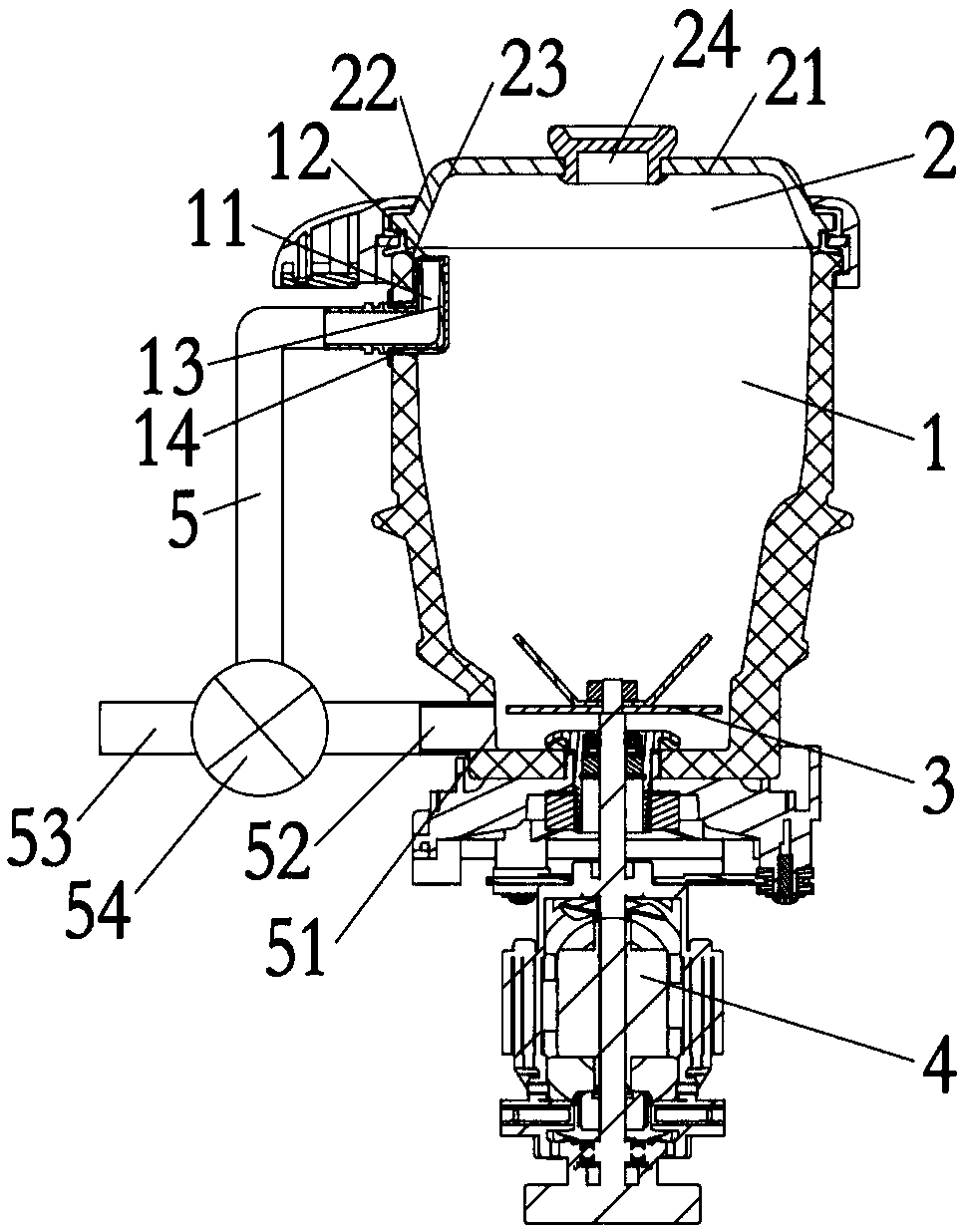

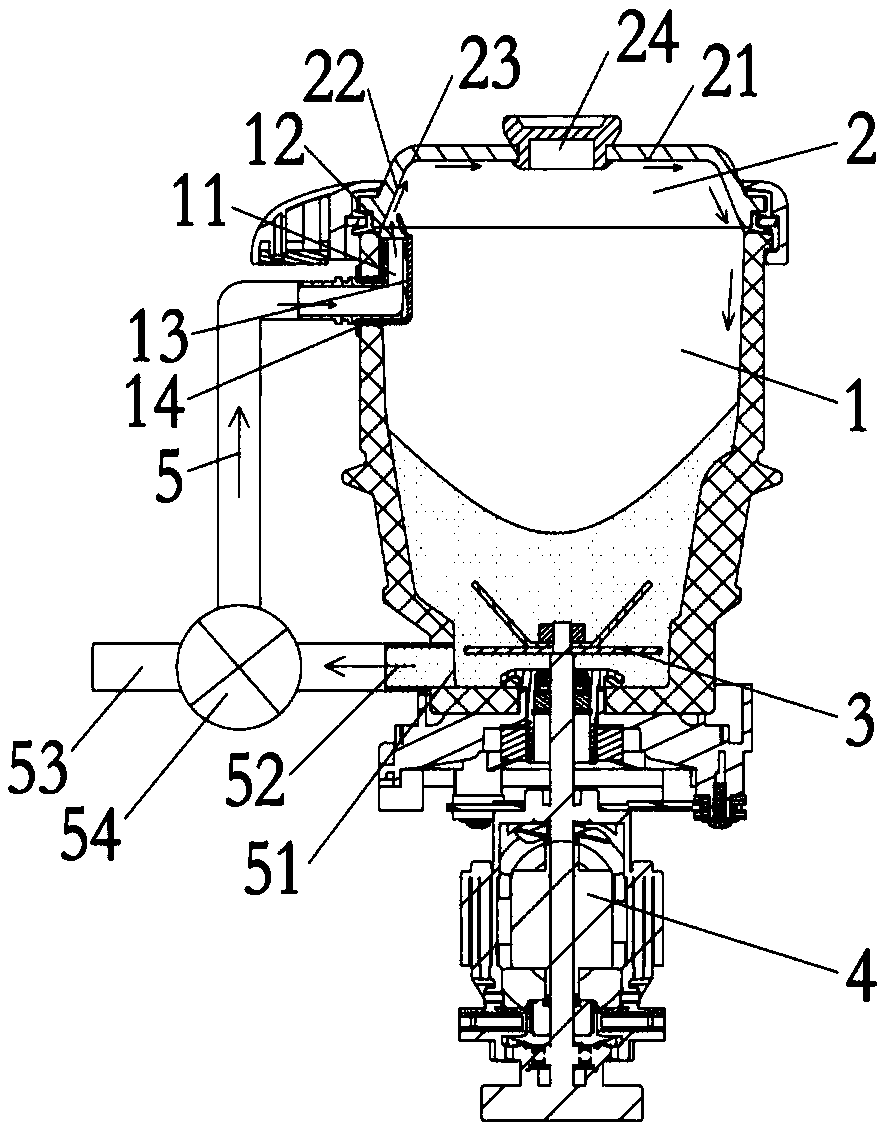

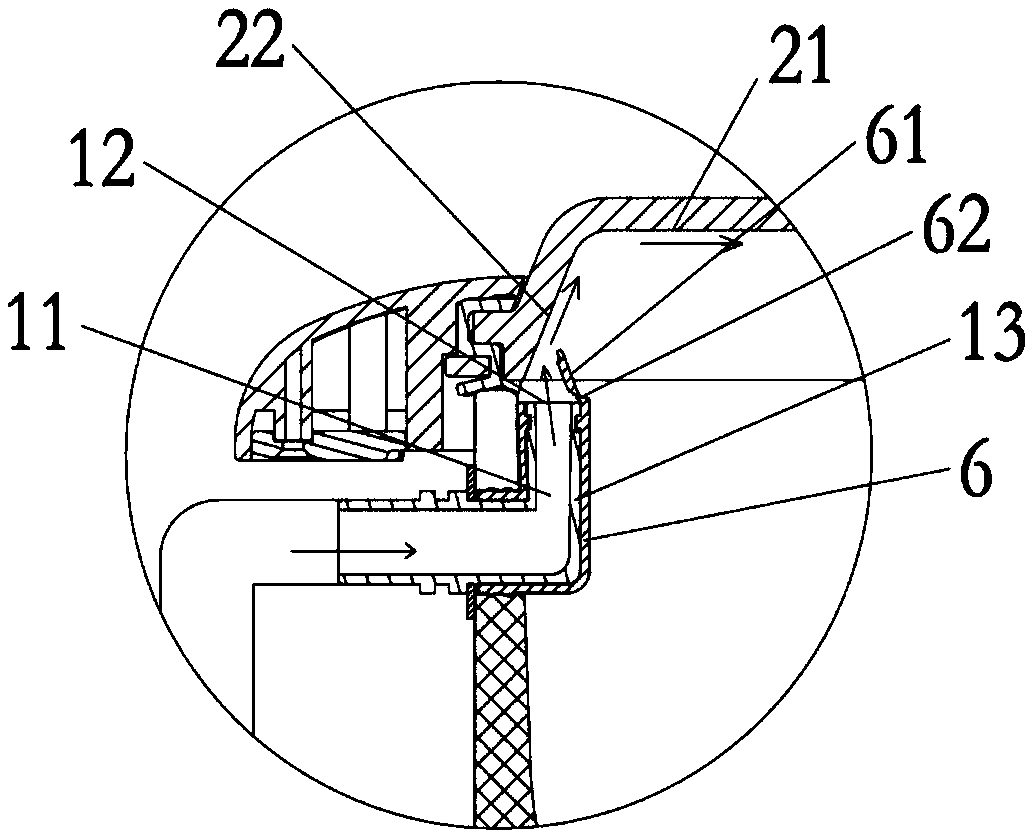

[0046] Such as Figure 1-Figure 5 As shown, a self-circulation cleaning food processing machine includes a container 1, a cup cover 2 installed in the container 1 and a crushing device 3, the cup cover 2 is located above the container 1 and is sealed with the container 1, the crushing device 3 is arranged in the container 1 and Driven by motor 4. There are many ways to seal between the cup cover 2 and the container 1. A sealing gasket can be provided on the outer edge of the cup cover 2. After the cup cover 2 is placed on the container 1, it can be compressed and fitted with the inner side of the cup to form a radial seal; or , a sealing gasket is arranged on the inner edge of the cup cover, and after the cup lid is placed on the container, it is compressed and fitted with the outside of the cup to form a radial seal; or, a sealing gasket is arranged between the end of the cup lid and the container cup edge, The cup cover and the container are fixed by the holding structure, ...

Embodiment 2

[0061] In this embodiment, the container includes a lower shell and an upper shell integrally sealed with the upper end of the lower shell, the upper shell and the lower shell are enclosed to form a cavity of the container; the nozzle is located in the On the wall of the upper casing, the nozzle penetrates the wall of the upper casing and extends into the cavity of the container.

[0062] Such as Figure 6-12 As shown, in this embodiment, the materials of the upper case 11A and the lower case 12A are different, the lower case 12A is a barrel-shaped glass part, the upper case 11A is a plastic part, and the lower case 12A and the upper case The body 11A is integrally molded by injection molding to realize the sealed connection between the upper shell 11A and the lower shell 12A. Moreover, in this embodiment, the upper case 11A is a curved plate with an opening on one side in the circumferential direction, and the connection surface between the upper case 11A and the lower case ...

Embodiment 3

[0079] In this embodiment, the container includes a cup body and a transition piece, the transition piece is located above the cup body and is integrally sealed with the upper end of the cup body, and the nozzle is located on the wall of the transition piece , the nozzle penetrates the wall of the transition piece and extends into the space enclosed by the cup cover, the transition piece and the cup body.

[0080] Such as Figure 12-17 As shown, the body 1B; the cup body 12B has a chamber for containing materials and is installed on the body 1B; the transition piece 11B is located above the cup body 12B and is sealed with the upper end of the cup body 12B; the cup cover 2B is closed On the transition piece 11B, and sealed with the transition piece 11B through the sealing part 3B; the nozzle 4B is located on the wall of the transition piece 11B, and the nozzle 4B penetrates the wall of the transition piece 11B and extends into the cup cover 2B, the transition piece In the spac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com