Mining hydrodynamic dust remover

A technology of mine water and dust collector, which is applied in dust prevention, mining equipment, liquid separation agent, etc. It can solve the problems of small atomization area, high water ejection speed, and troublesome operation, so as to increase the dust removal area, The effect of saving electricity cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

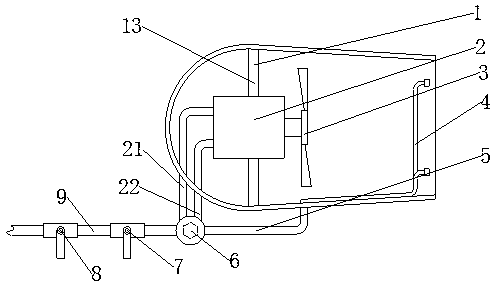

[0025] see Figure 1-4 , a mine hydrodynamic dust collector, including spray cover 1, hydraulic motor 2, fan blade 3, atomizing pipe 4, atomizing water inlet pipe 5, reversing valve 6, flow control valve 7, main valve 8 and inlet water pipe 9;

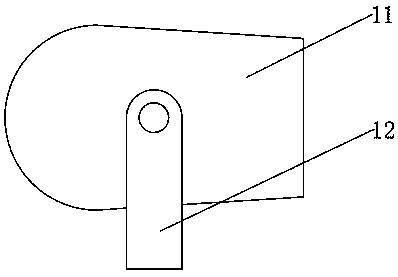

[0026] The spray cover 1 includes a cover body 11, a mounting frame 12 and a motor mounting frame 13; the mounting frame 12 is installed on the outside of the cover body 1, and is used to install the dust collector on the workbench; the motor mounting frame 13 Installed inside the cover body 1; the cover body 1 is a cylindrical structure, and the tail end of the cover body 1 is provided with a grid, and the front end of the cover body 1 is an open structure;

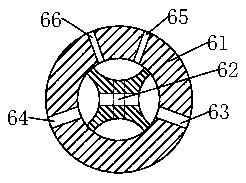

[0027] The hydraulic motor 2 is a vane type hydraulic motor, and the hydraulic motor 2 is installed on the motor mounting frame 13; further, in order to drive the hydraulic motor 2, the hydraulic motor 2 is provided with a hydraulic motor inlet pipe 21 and a hydraulic motor outl...

Embodiment 2

[0038] A mine dedusting equipment includes the mine hydrodynamic deduster described in Embodiment 1.

[0039] The working principle of this embodiment is consistent with that of Embodiment 1.

[0040] The beneficial effects of the present invention are: the present invention drives the fan to rotate through the hydraulic motor, so that the dust collector can work without being connected to electricity, which saves the cost of electricity, and the rotation of the hydraulic motor can absorb the energy in the water pressure, so that the atomizer can bear less The water pressure is adjusted to increase the dust removal area, which solves the problems of excessive energy consumption and inoperable operation of the dust removal equipment in the prior art. The invention controls the forward and reverse rotation of the hydraulic motor through the reversing valve, and the operation is simple.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com