Micropipettor based on automatic suction and transfer technology

A micropipette and technology, which is applied in the field of micropipettes, can solve the problems of limited and unsatisfactory taking accuracy, and achieve the effect of less human factors and high liquid taking accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

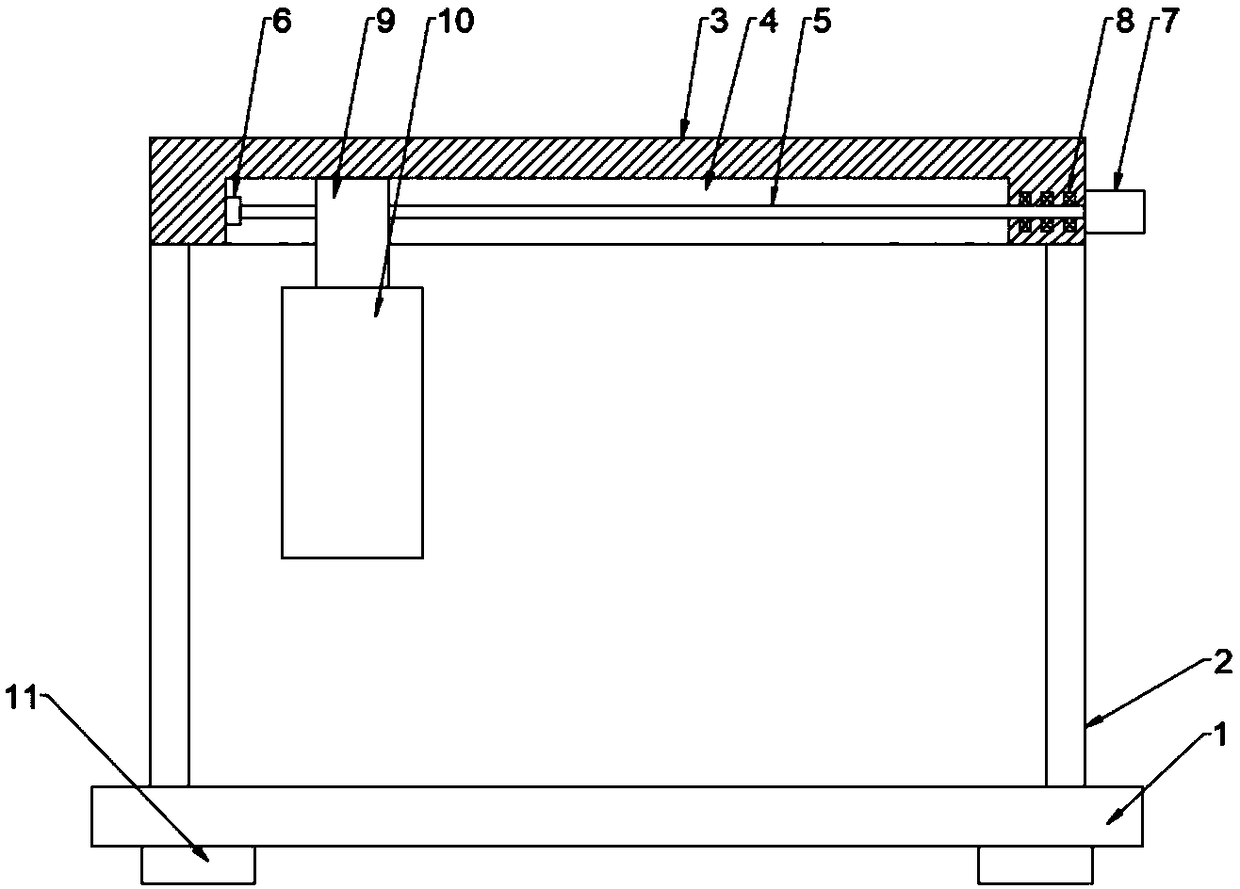

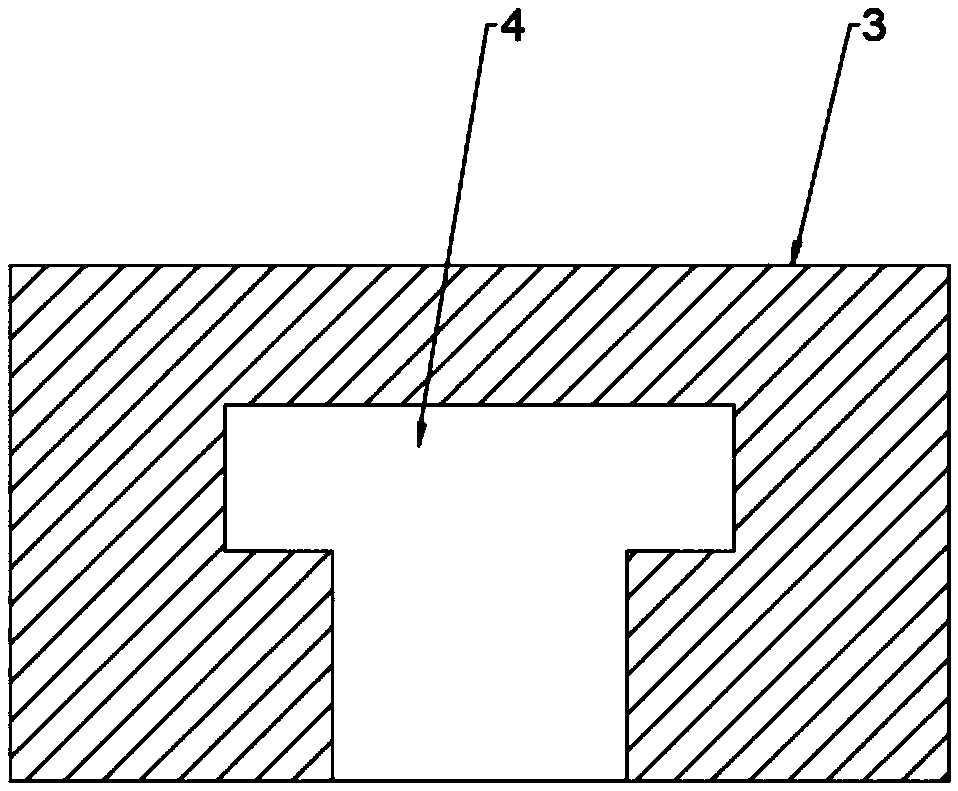

[0024] see Figure 1~3 , a micropipette based on automatic suction and transfer technology, comprising a base plate 1, a column 2, a beam 3 and a liquid-taking cylinder 10, the top surface of the base plate 1 is symmetrically provided with columns 2 on the left and right sides, and the two The top of column 2 is provided with crossbeam 3, and the bottom end of described crossbeam 3 is provided with chute 4, and described chute 4 is T-shaped groove, and the inner cavity of chute 4 is provided with screw mandrel 5, and chute 4 is connected with lead screw 5 are in a parallel relationship, one end of the screw 5 is rotatably connected to the inner cavity wall of the chute 4 through the bearing seat 6, and the other end of the screw 5 runs through the side end of the chute 4 and is fixedly connected to the motor 7 On the motor shaft, the motor 7 is fixedly connected to the crossbeam 3, the lead screw 5 is connected to the crossbeam 3 through the rotation of the bearing 8, the lead...

Embodiment 2

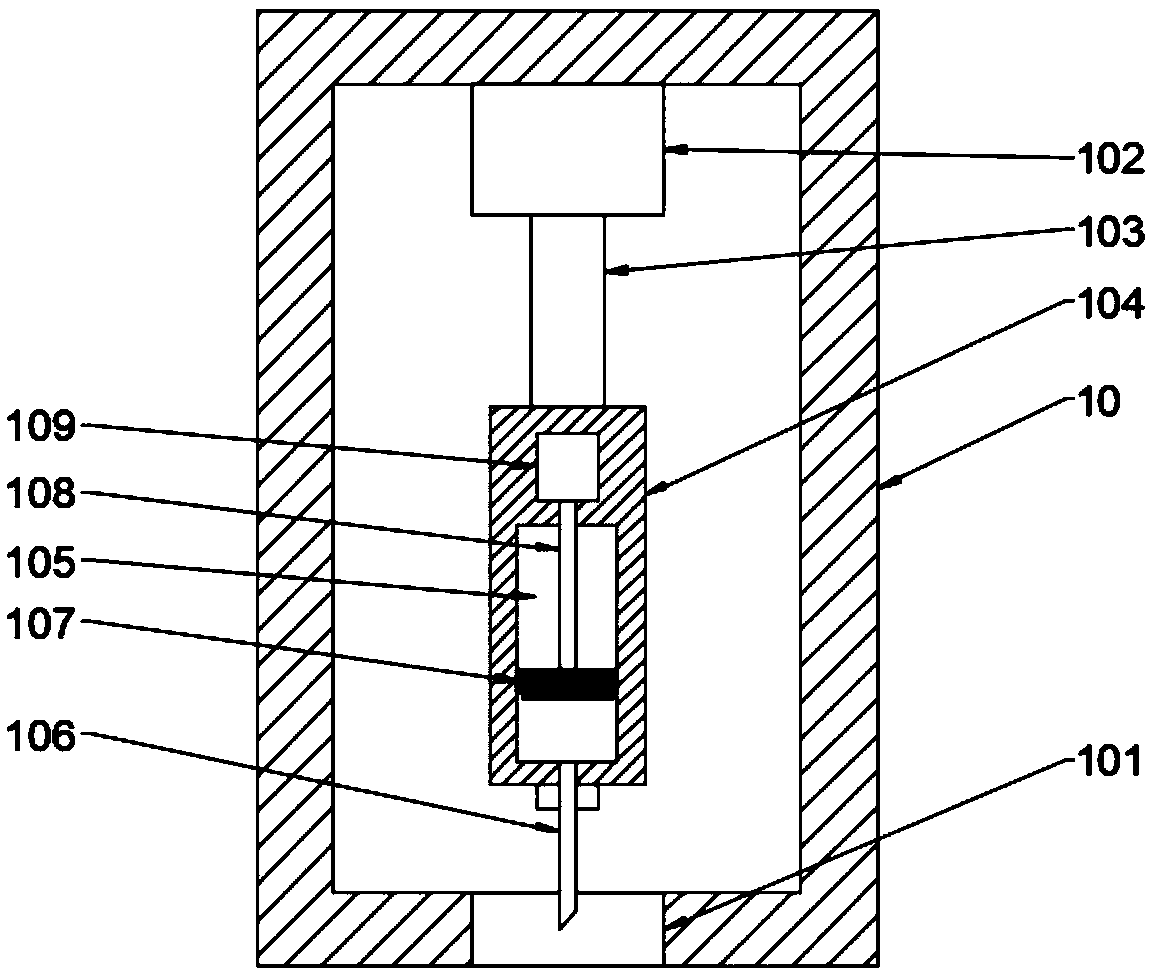

[0026] This embodiment is a further elaboration on the basis of Embodiment 1. A liquid-taking hole 101 is provided in the center of the bottom wall of the inner cavity of the liquid-taking cylinder 10, and a first electric telescopic Device 102, the bottom end of the first telescopic rod 103 on the first electric telescopic device 102 is fixedly connected with a liquid-taking column 104 matched with the liquid-taking hole 101, and the liquid-taking column 104 is a cylindrical structure, and the liquid-taking column 104 is a cylindrical structure. The axis of the column 104 coincides with the axis of the liquid-taking hole 101. The diameter of the liquid-taking column 104 is smaller than the diameter of the liquid-taking hole 101. A second electric telescopic device 109 and a liquid-taking cavity 105 are arranged in the liquid-taking column 104. The second electric telescopic device 109 is located above the liquid-taking chamber 105, and the bottom end of the second telescopic r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com