A Symmetrical Combined Spiral Grinding Cylinder and Its Design Method

A combined and spiral technology, applied in the direction of grain processing, etc., can solve the problems of agitator replacement, difficult maintenance, affecting the life of support bearings, reducing the filling rate of the cylinder, etc., so as to improve the grinding efficiency, improve the grinding effect, The effect of speeding up movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

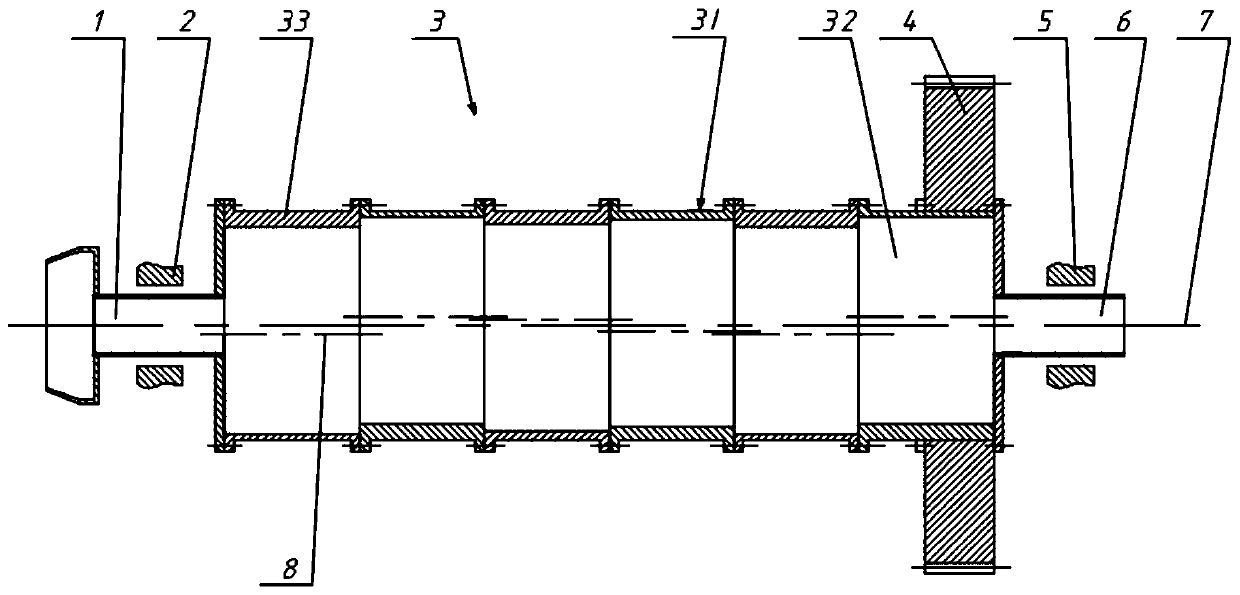

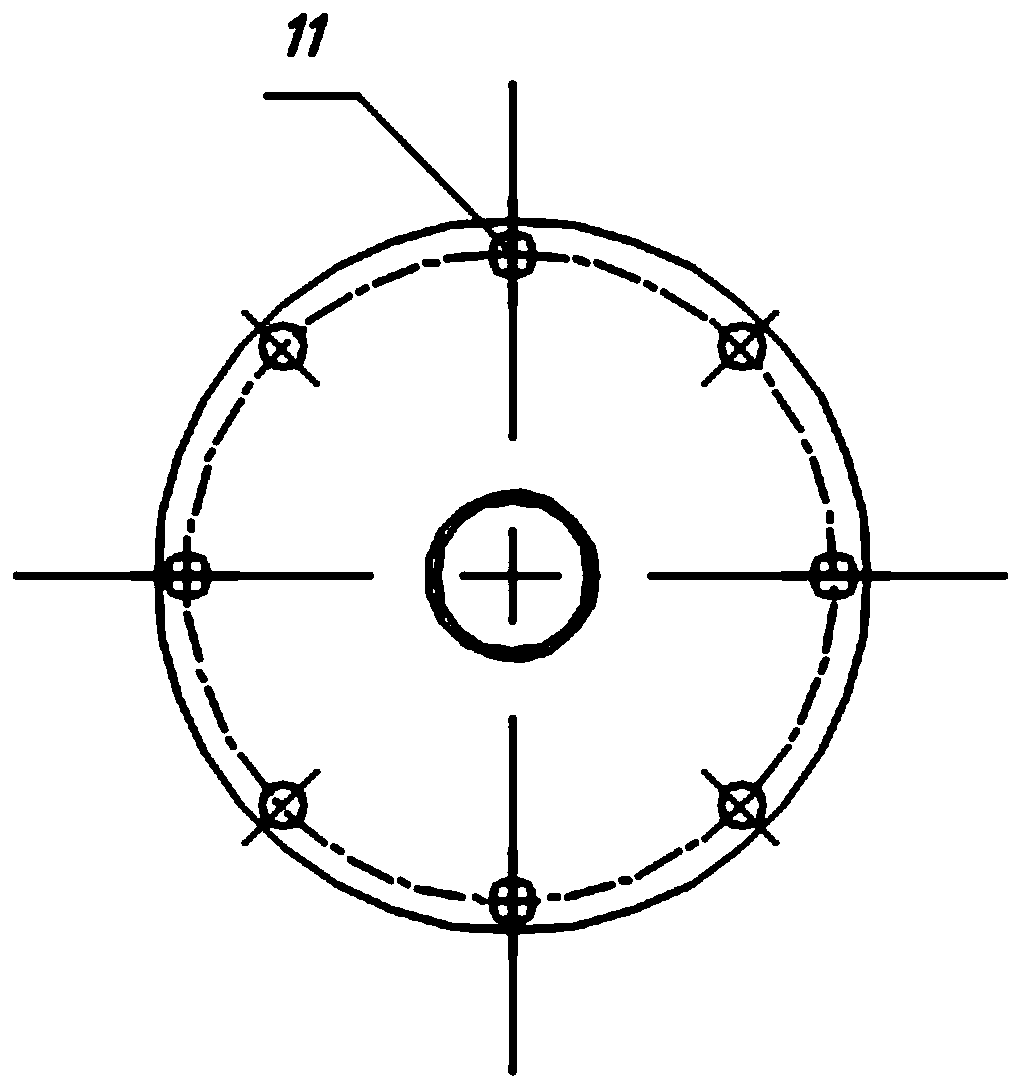

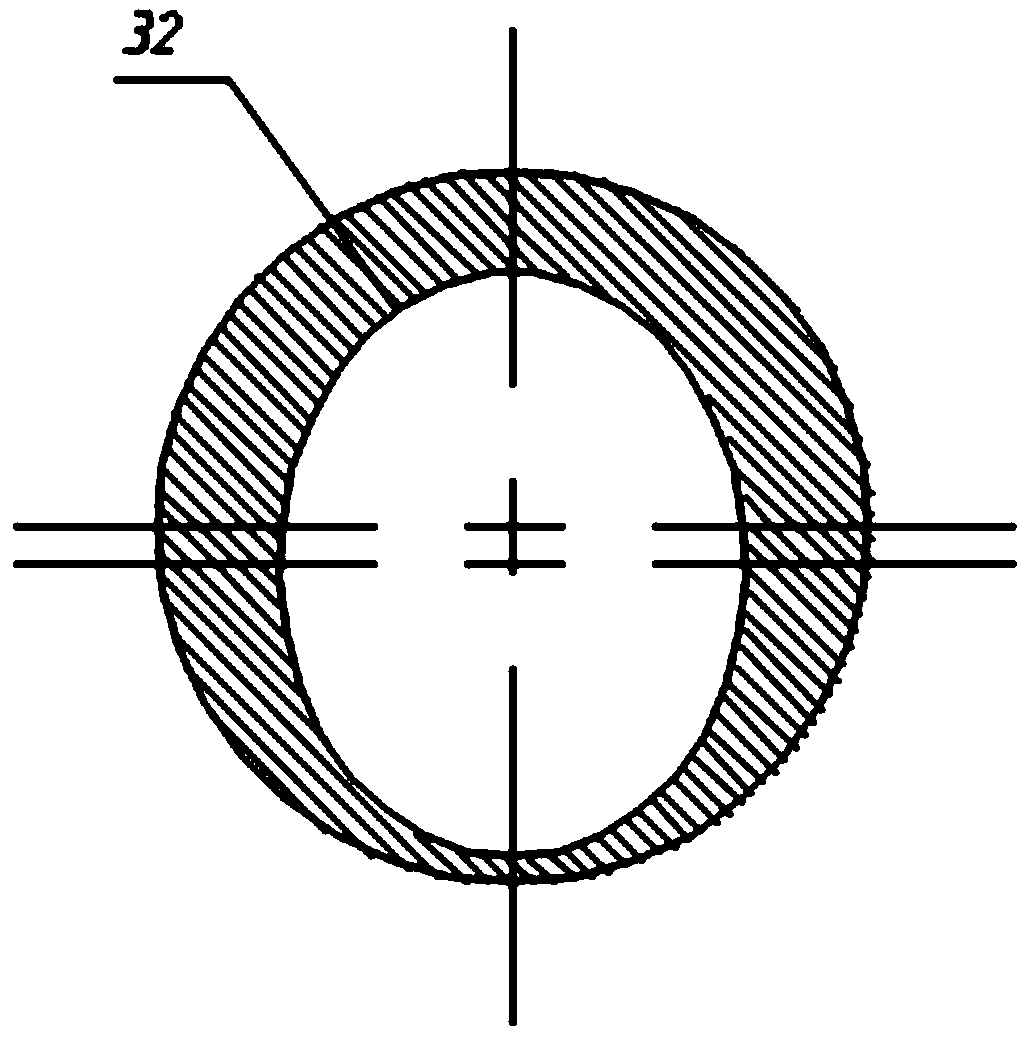

[0044] see Figure 1 - Figure 1 0.

[0045] The invention discloses a symmetrically combined spiral grinding cylinder, which comprises a cylinder 3, a feed throat 1 communicated with the ends of the cylinder 3, a discharge throat 6 and a transmission gear 4, the The outer walls of the middle part of the feed throat 1 and the discharge throat 7 are respectively equipped with a frame left support 2 and a frame right support 5. The cylinder body 3 is formed by docking and combining several eccentric cylinders 31; the eccentric cylinder 31 includes an inner cylinder 32 and an outer cylinder 33. There is an eccentricity between the axis of the inner cylinder 32 and the axis of the outer cylinder 33. Through the existence of the eccentricity, each eccentric cylinder drives the material and the grinding medium to rotate around the axis of rotation. Revolving, the "dead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com