Novel adjustable machining equipment for ribbed steel bars

A ribbed steel bar and processing equipment technology, applied in metal processing equipment, manufacturing tools, tangent devices, etc., can solve the problems of reduced speed of finished pile foundation reinforcement cages, labor-intensive, no production and operation platform, etc., to improve processing efficiency, The effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in detail below in conjunction with accompanying drawing:

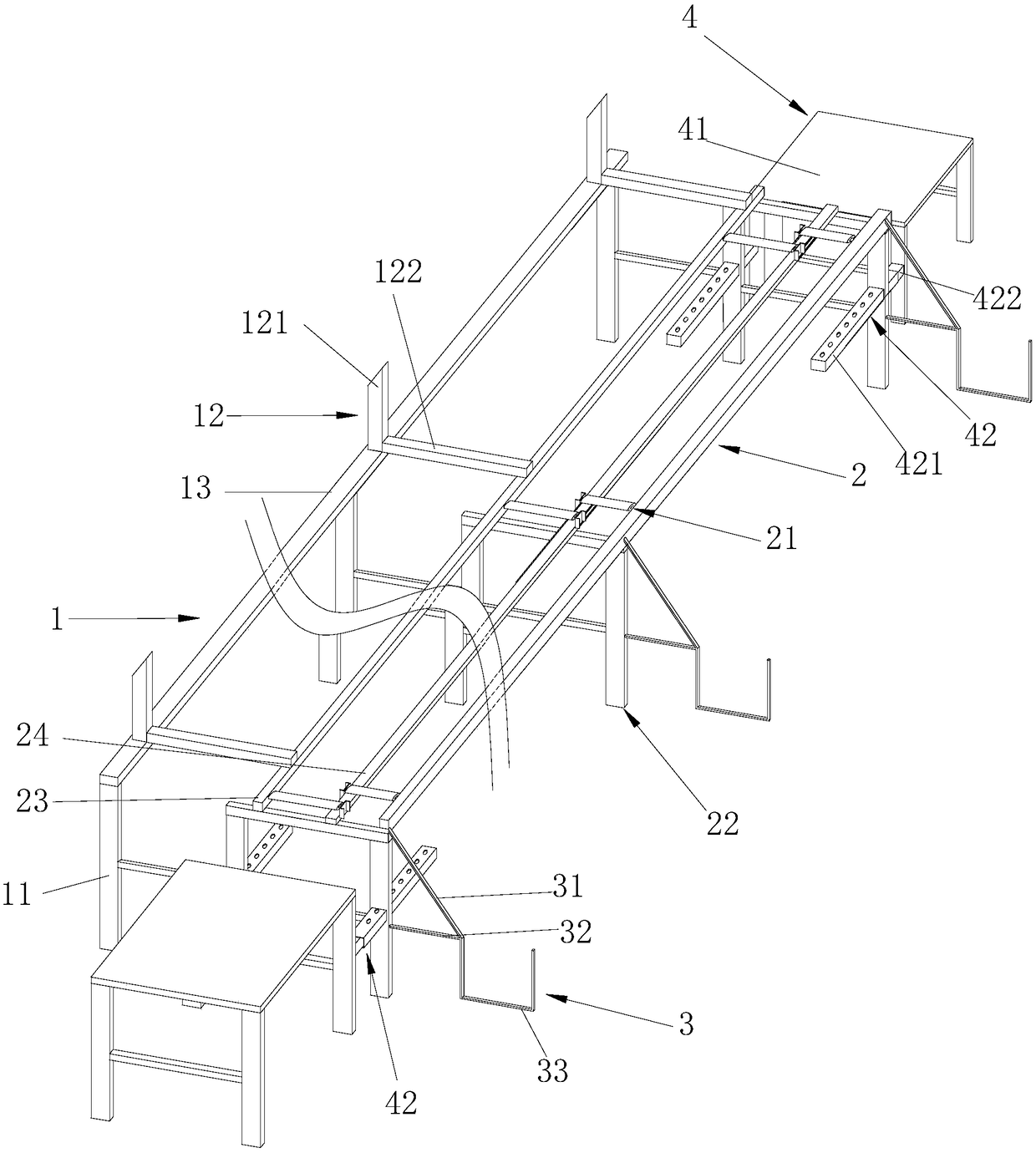

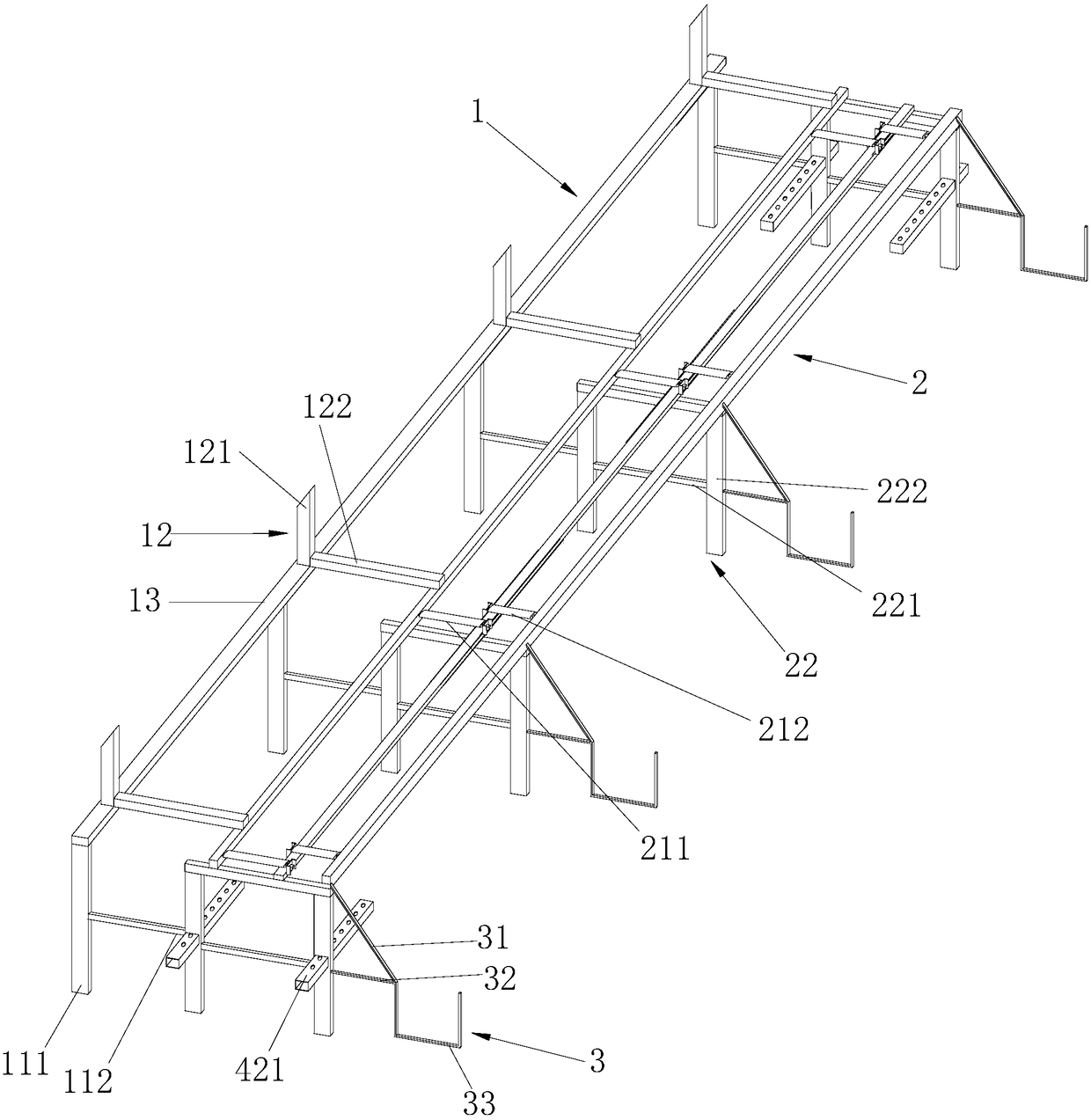

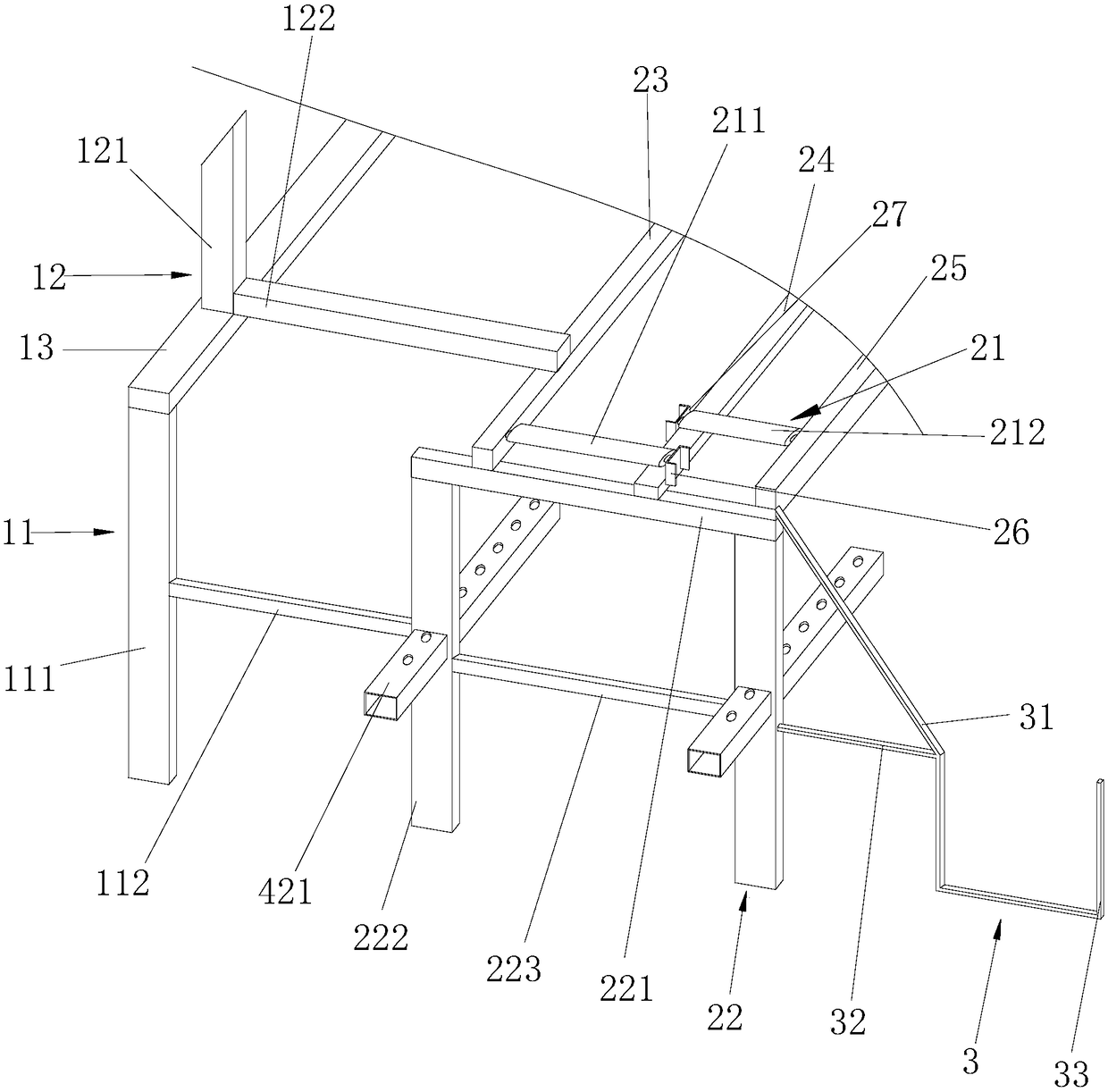

[0031] combine Figure 1 to Figure 7 , a new type of adjustable processing equipment for ribbed steel bars, including a raw material storage mechanism 1, a processing support mechanism 2, a finished product storage mechanism 3 and an adjustment platform mechanism 4, and the processing support mechanism 2 includes multiple groups of roller assemblies 21 and multiple The first brace 22, the upper end of a plurality of first braces 22 is provided with the first brace 23, the second brace 24 and the third brace 25, the first brace 23, the second brace 24 and the third brace The rods 25 are arranged parallel to each other.

[0032] The roller assembly 21 includes a first roller 211 and a second roller 212. The rear end of the first roller 211 is connected to the first strut 23 through a bearing, and the front end of the first roller 211 is connected to the second strut 24 through ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap