A clamping method and device for finishing the circular arc surface of a connecting rod

A technology for clamping the arc surface and the workpiece, which is applied in the direction of grinding the workpiece support, etc., can solve the problem of time-consuming, arc surface roughness, arc and inner hole coaxiality can not reach the finish machining, workpiece weight and other problems, to achieve the effect of simple installation, significant economic benefits and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

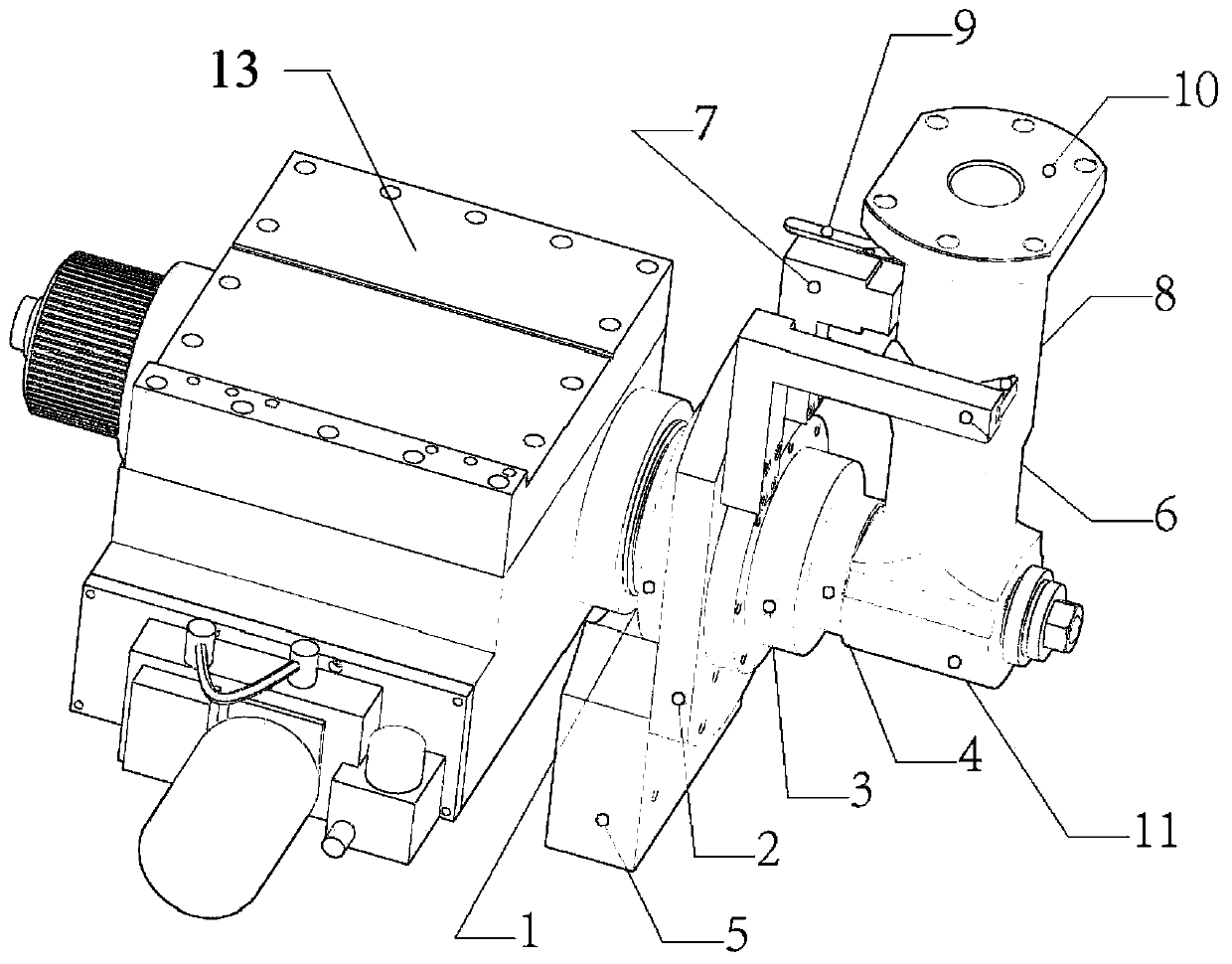

[0027] The present invention will be further described below with reference to the accompanying drawings and embodiments.

[0028] A method for clamping the arc surface of a finishing connecting rod of the present invention comprises the following steps:

[0029] (1) Use the headstock rotating mandrel conical surface locking nut to lock the headstock flange and the rotating mandrel of the grinding machine headstock;

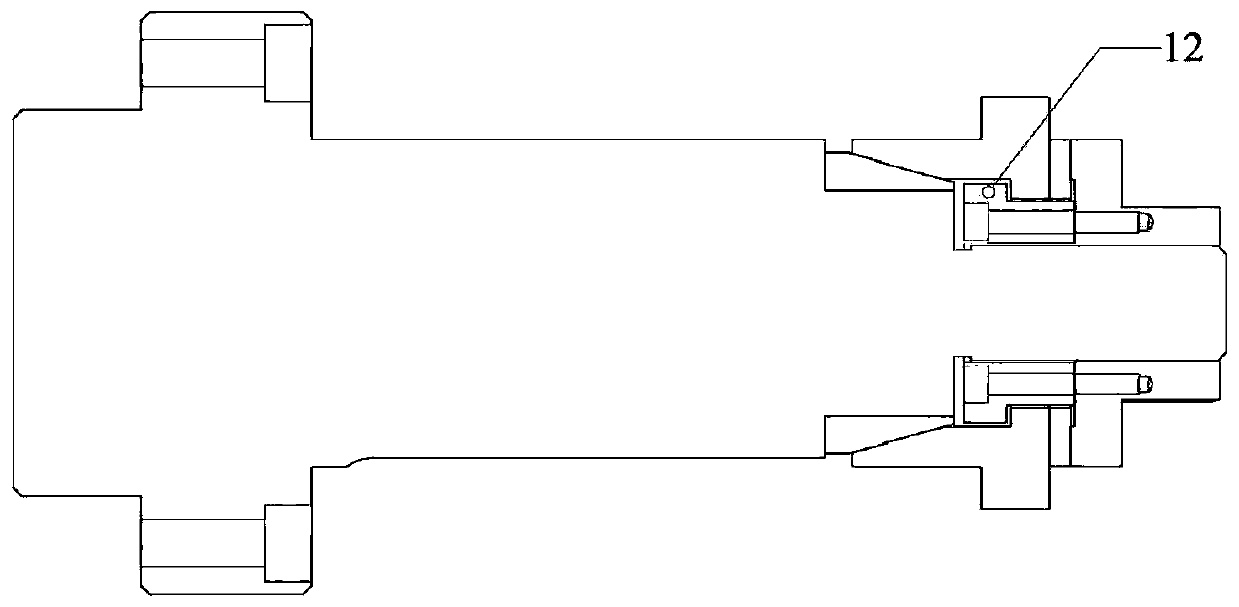

[0030] (2) Install the flange of the fixed seat on the front side of the flange of the head frame, adjust the flange of the fixed seat and the flange of the head frame to be coaxial, and then lock and fix with screws; the bottom of the flange of the fixed seat Equipped with a counterweight, and the upper part of the flange of the fixed seat is provided with two clamping seats;

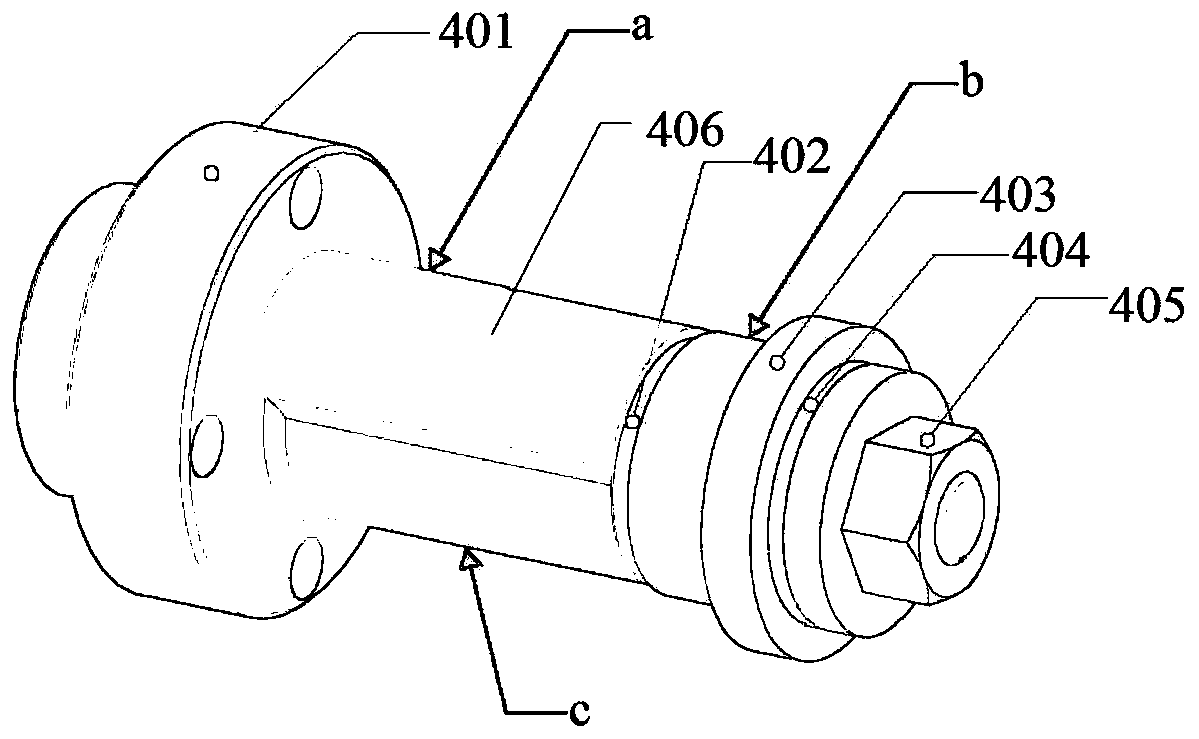

[0031] (3) Install the connecting flange of the clamping mandrel on the front side of the flange of the fixed seat, adjust the connecting flange of the clamping mandrel and the flange of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com