Method for treating organic pollutants by using chitosan modified active coke to support nano-gold catalyst in situ

A technology of organic pollutants and activated coke, which is applied in the direction of water pollutants, organic compounds/hydrides/coordination complex catalysts, chemical instruments and methods, etc. Secondary pollution and other problems, achieve good application value and application range, improve mechanical stability, and stabilize chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

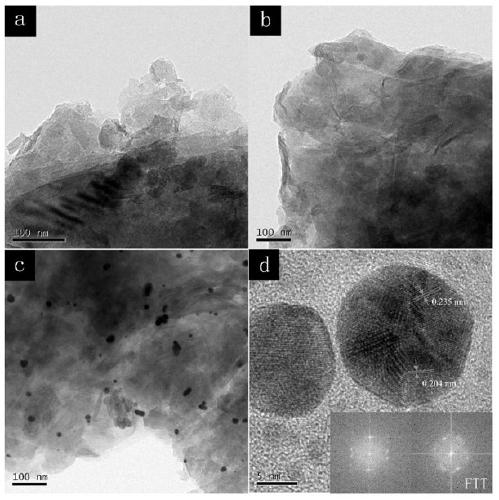

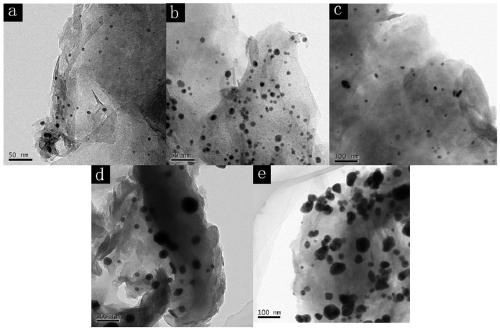

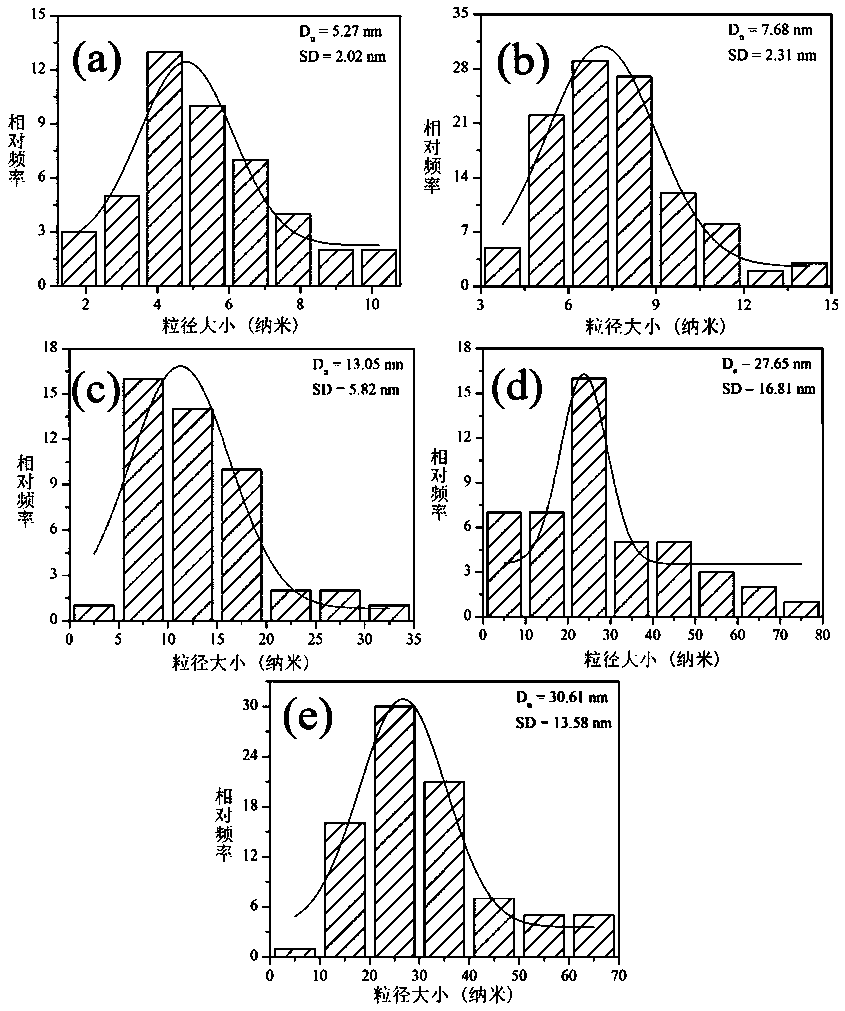

[0049] A method for treating organic pollutants (nitroaromatic compounds) by using chitosan-modified active coke to load nano-gold catalysts in situ, specifically, using chitosan-modified active coke to load nano-gold catalysts in situ to treat 4-nitrate in water Catalytic treatment of phenylphenol (4-NP), including the following steps:

[0050] (1) Weigh 5 mg of chitosan-modified activated coke in situ loaded nano-gold catalyst (Au NPs / CTS / AC (1) 、AuNPs / CTS / AC (2) 、Au NPs / CTS / AC (3) 、Au NPs / CTS / AC (4) 、Au NPs / CTS / AC (5) ), were added to 50 mL of 4-nitrophenol solution with a concentration of 0.2 mM, and stirred for 30 min, so that the chitosan-modified activated coke in situ loaded nano-gold catalyst reached adsorption equilibrium.

[0051](2) Weigh 5 parts of sodium borohydride, each 0.0757g, and add to the mixed solution obtained after stirring in step (1) respectively (the molar ratio of 4-nitrophenol in the mixed solution to sodium borohydride=1: 200), stir evenly, a...

Embodiment 2

[0078] A method for treating organic pollutants (nitroaromatic compounds) by using chitosan-modified active coke to load nano-gold catalysts in situ, specifically, using chitosan-modified active coke to load nano-gold catalysts in-situ to treat 2-nitrate in water Carry out catalytic treatment of base phenol, comprise the following steps:

[0079] (1) Weigh 5 mg of the chitosan-modified active coke prepared in Example 1 to load nano-gold catalyst in situ (Au NPs / CTS / AC (1) ), was added to 50 mL of 2-nitrophenol solution with a concentration of 0.2 mM, and stirred until the chitosan-modified activated coke loaded nano-gold catalyst in situ reached adsorption equilibrium.

[0080] (2) Weigh 0.0757g of sodium borohydride, add it into the mixed solution obtained after stirring in step (1), stir evenly, carry out catalytic reduction reaction at room temperature, and complete the treatment of 4-nitrophenol in the water body. Immediately after adding sodium borohydride and mixing, an...

Embodiment 3

[0083] A method for treating organic pollutants (nitroaromatic compounds) by using chitosan-modified active coke to load nano-gold catalysts in situ, specifically, using chitosan-modified active coke to load nano-gold catalysts in-situ to treat 3-nitrate in water Catalytic treatment of phenylphenol (3-NP), including the following steps:

[0084] (1) Weigh 5 mg of the chitosan-modified activated coke prepared in Example 1 to load nano-gold catalyst in situ (Au NPs / CTS / AC (1) ), was added to 50 mL of 3-nitrophenol solution with a concentration of 0.2 mM, and stirred until the chitosan-modified activated coke in situ loaded nano-gold catalyst reached adsorption equilibrium.

[0085] (2) Weigh 0.0757g of sodium borohydride, add it to the mixed solution obtained after stirring in step (1), stir evenly, carry out catalytic reduction reaction at room temperature, and complete the treatment of 3-nitrophenol in the water body. Immediately after adding sodium borohydride and mixing, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com