Photoelectrochemical analysis method based on pd quantum dots modified tio2 nanorods and its application

An analysis method, nanorod technology, applied in chemical analysis by catalysis, analysis by making materials undergo chemical reactions, electrochemical variables of materials, etc., can solve the problem that it is difficult to effectively realize the reduction and desorption of chlorinated organic chemicals. Halogen and other problems, to achieve good reproducibility, improve selectivity, high selectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A Modified TiO Based on Pd Quantum Dots 2 Nanorod photoelectrochemical analysis method, the working electrode is Pd quantum dot modified TiO 2 Nanorods are obtained through the following steps:

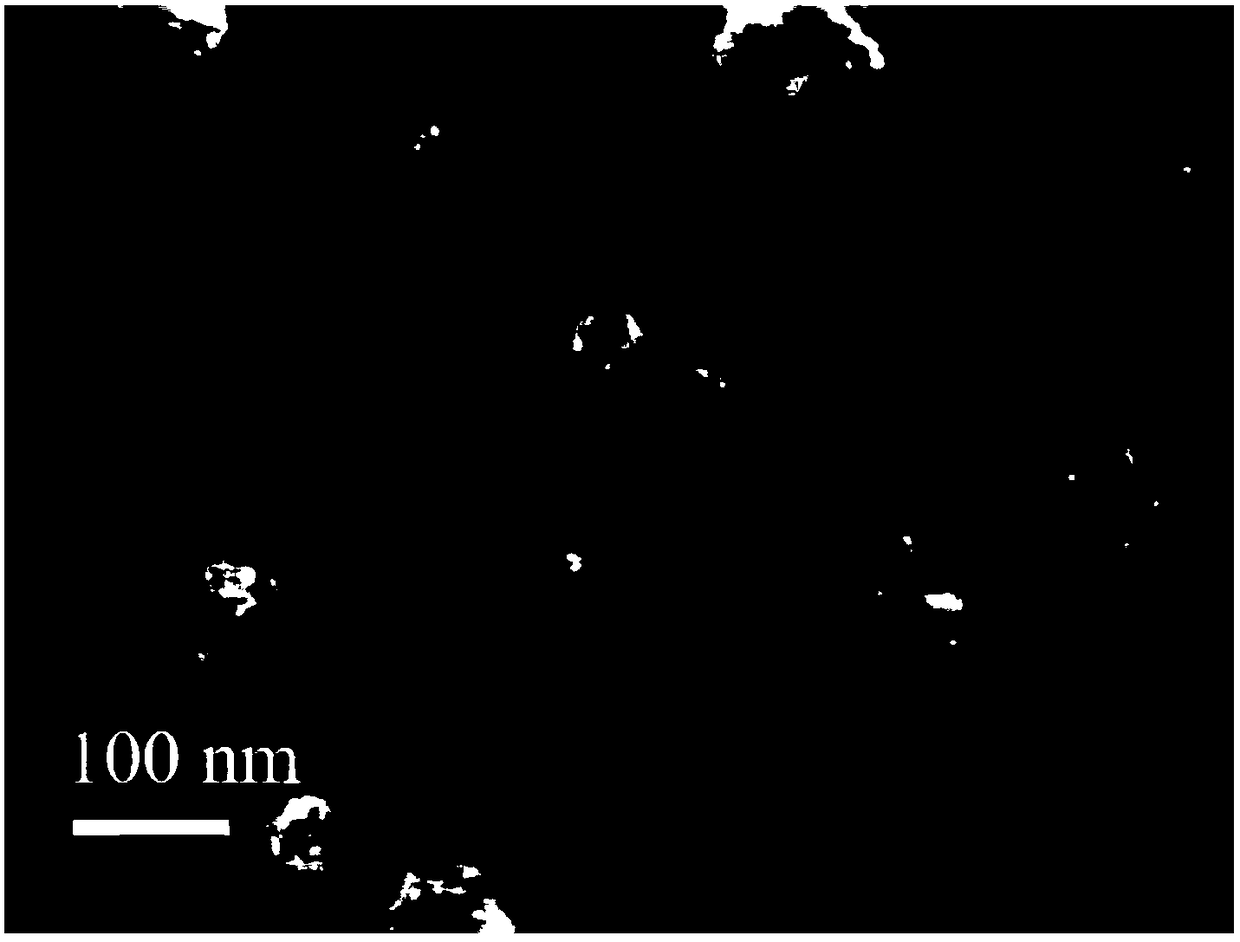

[0042] Using low-temperature hydrothermal method to prepare molecularly imprinted (SC, MI)-TiO with template molecule PCB101 on FTO substrate 2 NRs electrode; the electrode is calcined in a muffle furnace at 500℃ to remove the template molecules to obtain TiO 2 Nanorods; 800mg polyvinylpyrrolidone (PVP), 9mg palladium chloride (PdCl 2 ) And 300mg NaI in 13ml H 2 In O, after stirring evenly, transfer the above mixed solution into a 25ml polytetrafluoro stainless steel autoclave. TiO 2 The nanorods were placed in the mixed solution and reacted hydrothermally for 1.5 hours at a constant temperature of 180°C. After cooling to room temperature, the electrode was taken out and washed with double distilled water, and the surface was dried with nitrogen to obtain Pd quantum dot modified Ti...

Embodiment 2

[0050] A Modified TiO Based on Pd Quantum Dots 2 The photoelectrochemical analysis method of nanorods includes the following steps:

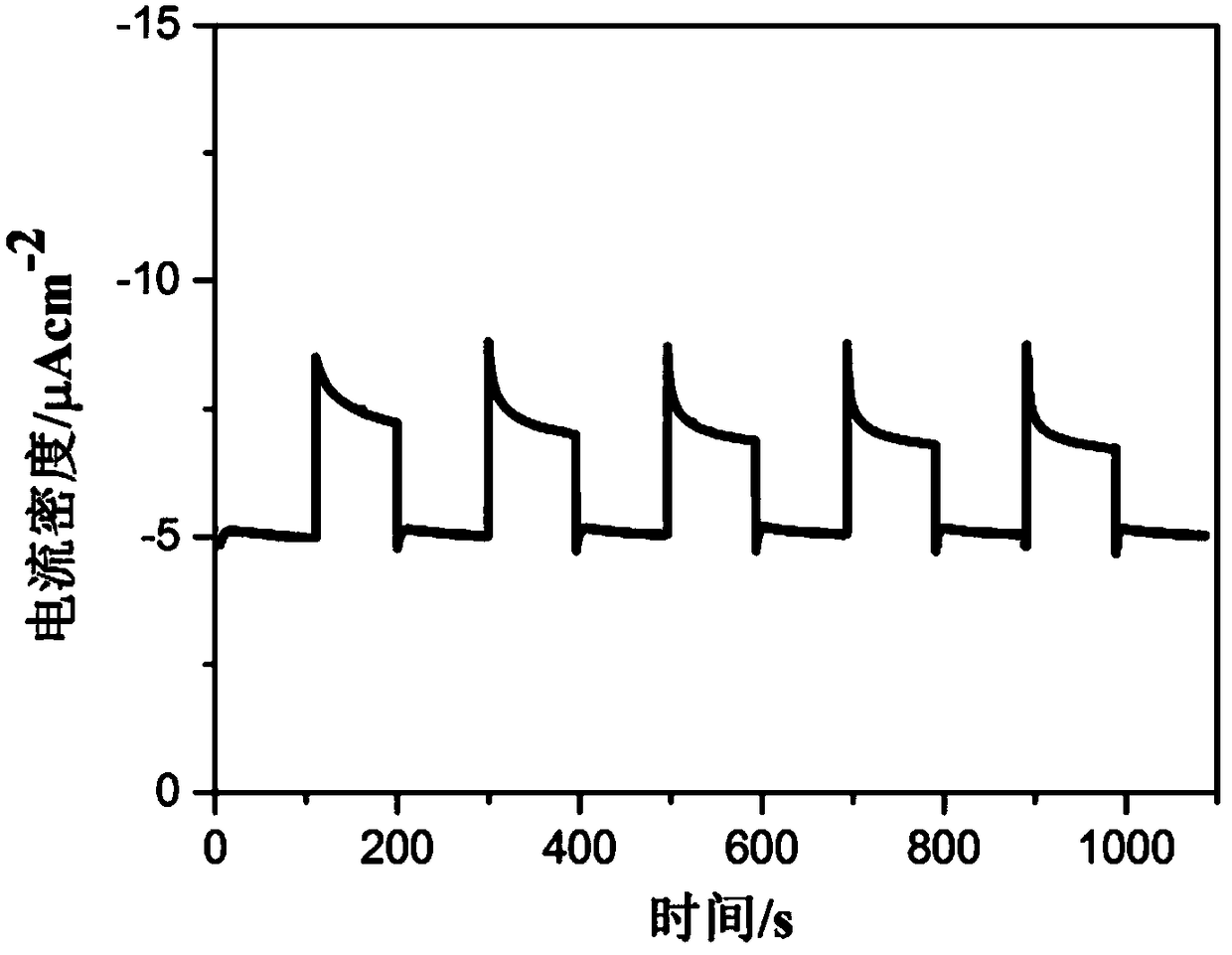

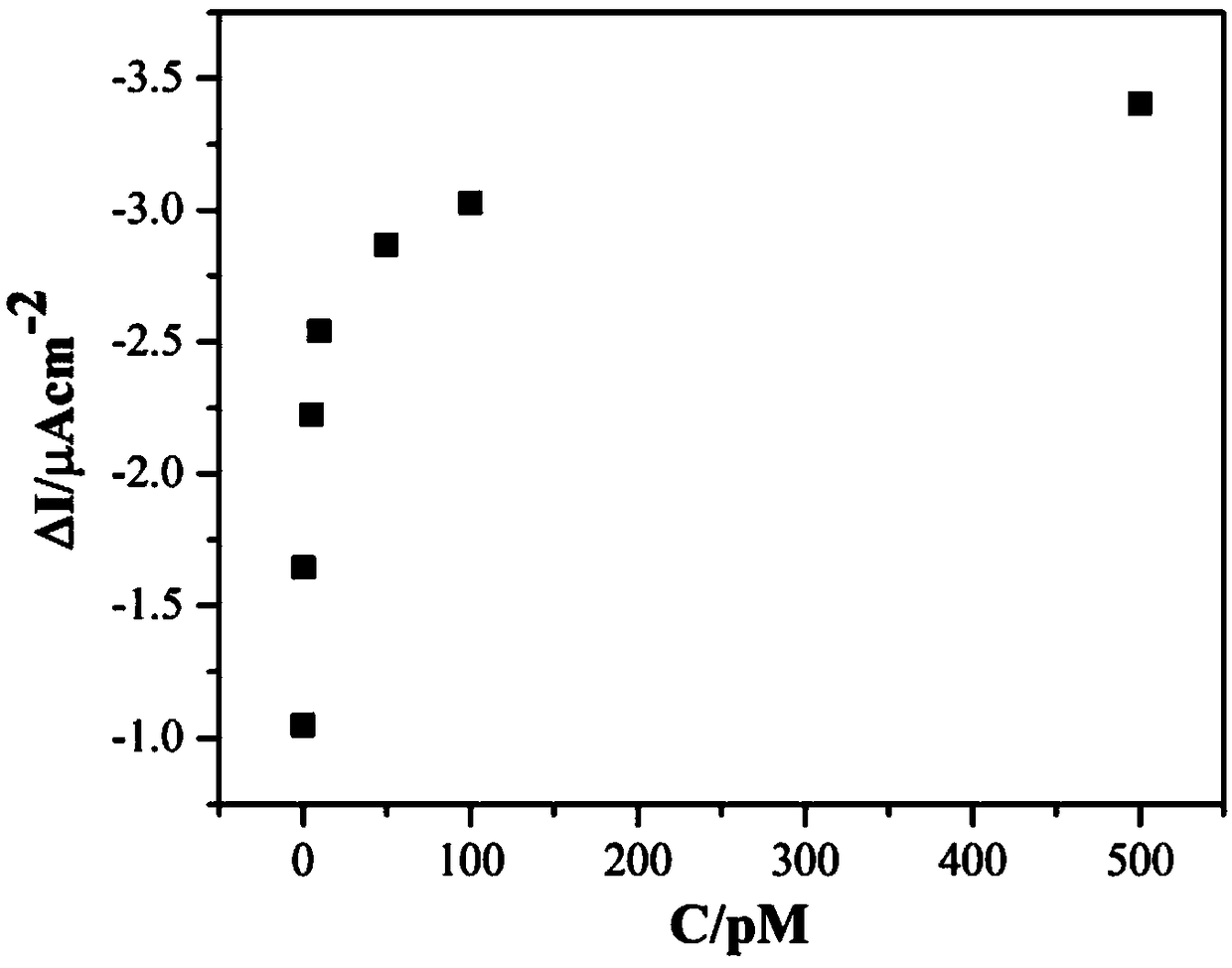

[0051] (1) Dissolve PCB101 in distilled water and prepare a concentration range of 10 -10 ~10 -7 Multiple sets of PCB101 standard solutions of mol / L;

[0052] (2) Preparation of Pd quantum dots modified TiO 2 Nanorods: (SC, MI)-TiO with template molecule PCB101 molecular imprinting was prepared on FTO substrate by low-temperature hydrothermal method 2 NRs electrode, and (SC,MI)-TiO 2 The NRs electrode is placed in a muffle furnace and calcined at 400°C to remove the template molecules to obtain TiO 2 Nanorods; then mix polyvinylpyrrolidone, palladium chloride, and NaI in a mass ratio of 800:5:200, and add them to 10mL of distilled water to obtain a mixed solution; then combine the TiO obtained in step (a) 2 The nanorods and the mixed solution obtained in step (b) are placed in a reactor, reacted at 150°C for 1 hour, cooled, washed with distilled water,...

Embodiment 3

[0057] A test method similar to that of Example 2 is adopted, and the specific steps are as follows:

[0058] (1) Dissolve PCB101 in distilled water and prepare a concentration range of 10 -10 ~10 -7 Multiple sets of PCB101 standard solutions of mol / L;

[0059] (2) Preparation of Pd quantum dots modified TiO 2 Nanorods: (SC, MI)-TiO with template molecule PCB101 molecular imprinting was prepared on FTO substrate by low-temperature hydrothermal method 2 NRs electrode, and (SC,MI)-TiO 2 The NRs electrode is placed in a muffle furnace and calcined at 500℃ to remove the template molecules to obtain TiO 2 Nanorods; then mix polyvinylpyrrolidone, palladium chloride, and NaI in a mass ratio of 800:10:500 and add them to 20mL of distilled water to obtain a mixed solution; then combine the TiO obtained in step (a) 2 The nanorods and the mixed solution obtained in step (b) are placed in a reactor, reacted at 100°C for 1 hour, cooled, washed with distilled water, and N 2 Blow dry to get the Pd ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com