A method for preparing amino compounds by catalytically reducing aromatic nitro compounds with high efficiency

A technology of amino compounds and aromatic nitro groups, applied in the field of reduction of aromatic nitro compounds, can solve problems such as slow catalytic rate of catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Press Ru 3+ : PVP monomer molar ratio is 1:10, weigh a certain amount of RuCl 3 ·nH 2 O and PVP, fully dissolve them in 10 ml of n-propanol under ultrasound, pour the above mixed solution into a 50 ml round bottom flask, add a stirring bar, stir rapidly at room temperature in a water bath for 10 hours, the solution turns from brownish red to final Turned brown, that is, the reaction is complete. Mix the original solution with the precipitating agent acetone 1:3 and then centrifuge. After centrifuging at 8000 rpm for 5 minutes, take the precipitate and wash it with water. Repeatedly washing with acetone and deionized water for 3-5 times, the obtained precipitate is dissolved in water to become an aqueous solution of ruthenium nanoparticles.

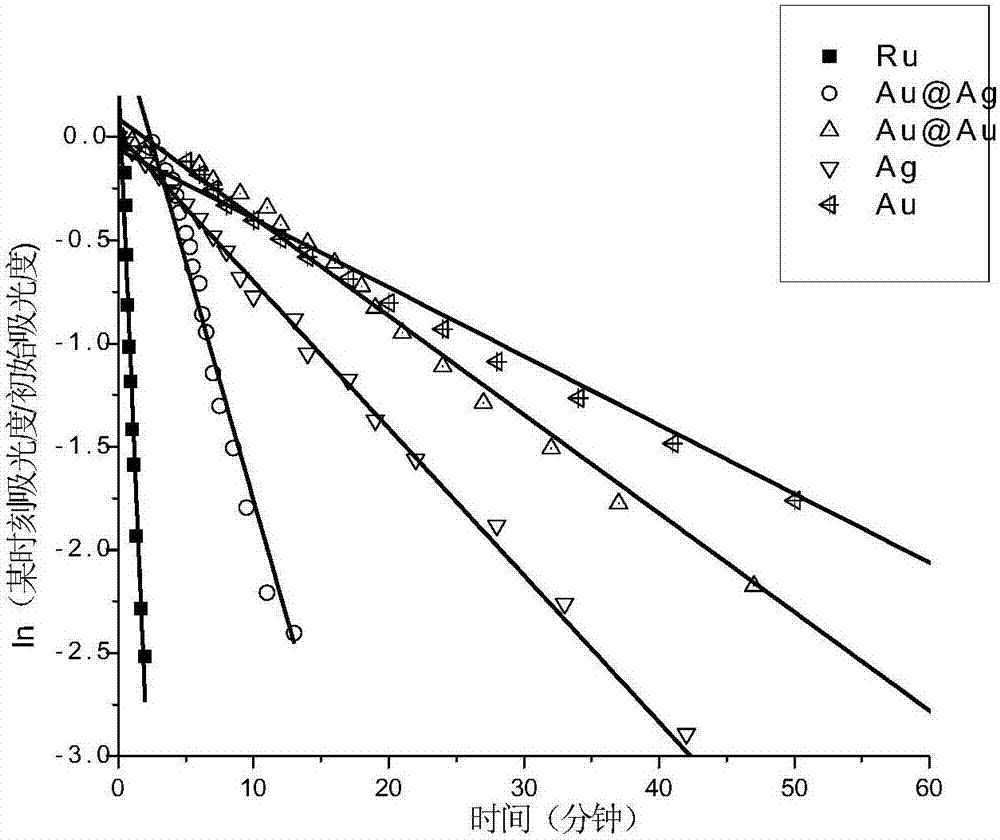

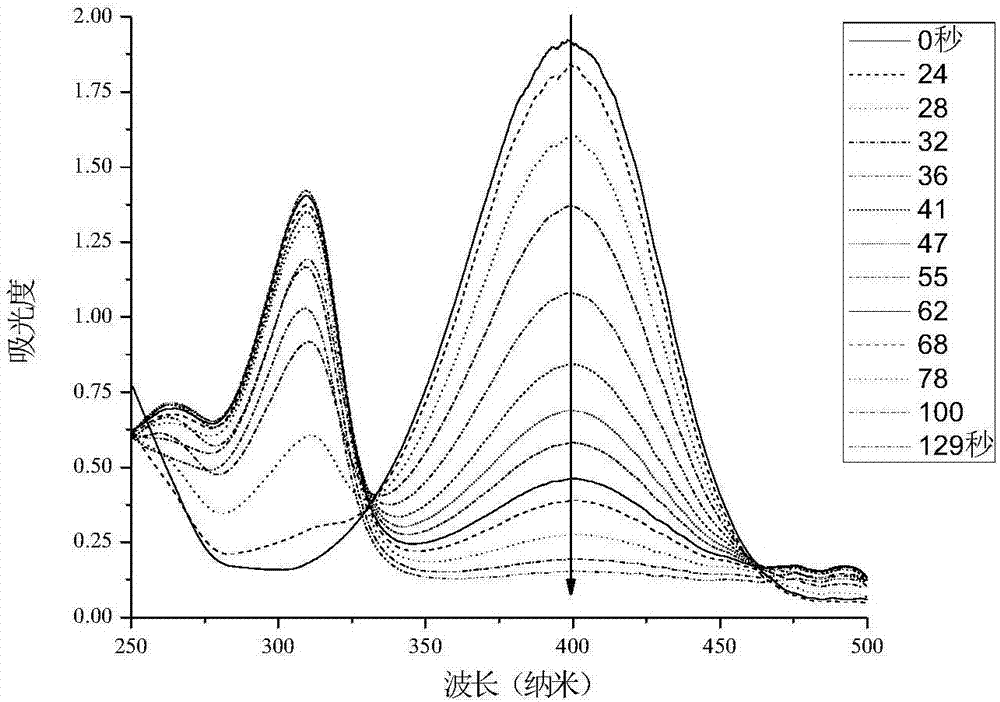

[0026] Add 2 ml of 0.1 mol / L freshly prepared sodium borohydride solution and 10 μL of 10 -2 mol / liter prepared p-nitrophenol aqueous solution, and finally add a small amount of synthesized ruthenium nanoparticle aqueous solutio...

Embodiment 2

[0028] Press Ru 3+ : PVP monomer molar ratio is 1:10, weigh a certain amount of RuCl 3 ·nH 2 O and PVP, fully dissolve them in 10 ml of n-propanol under ultrasound, pour the above mixed solution into a 50 ml round bottom flask, add a stirring bar, stir rapidly at room temperature in a water bath for 10 hours, the solution turns from brownish red to final Turned brown, that is, the reaction is complete. Mix the original solution with the precipitating agent acetone 1:3 and then centrifuge. After centrifuging at 8000 rpm for 5 minutes, take the precipitate and wash it with water. Repeatedly washing with acetone and deionized water for 3-5 times, the obtained precipitate is dissolved in water to become an aqueous solution of ruthenium nanoparticles.

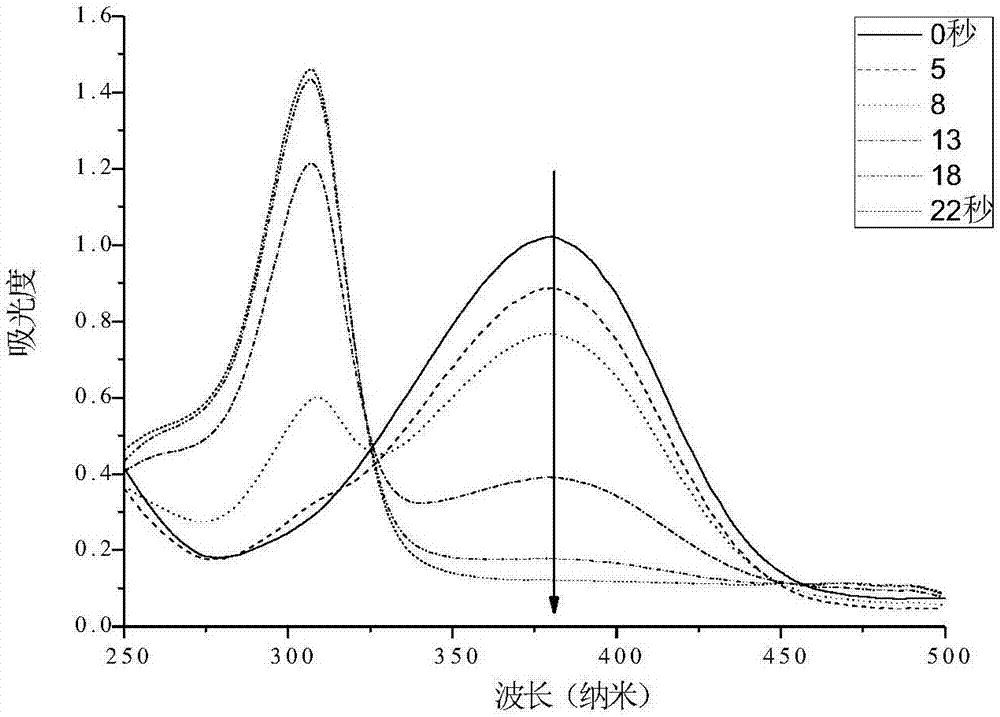

[0029] Add 2 ml of 0.1 mol / L freshly prepared sodium borohydride solution and 10 μL of 10 -2 mol / liter prepared p-nitroaniline ammonia solution, and finally add a small amount of synthesized ruthenium nanoparticle aqueous soluti...

Embodiment 3

[0031] Press Ru 3+ : PVP monomer molar ratio is 1:10, weigh a certain amount of RuCl 3 ·nH 2 O and PVP, fully dissolve them in 10 ml of n-propanol under ultrasound, pour the above mixed solution into a 50 ml round bottom flask, add a stirring bar, stir rapidly at room temperature in a water bath for 10 hours, the solution turns from brownish red to final Turned brown, that is, the reaction is complete. Mix the original solution with the precipitating agent acetone 1:3 and then centrifuge. After centrifuging at 8000 rpm for 5 minutes, take the precipitate and wash it with water. Repeatedly washing with acetone and deionized water for 3-5 times, the obtained precipitate is dissolved in water to become an aqueous solution of ruthenium nanoparticles.

[0032] Add 2 ml of 0.1 mol / L freshly prepared sodium borohydride solution and 10 μL of 10 -2 mol / liter prepared p-chloronitrobenzene aqueous solution, and finally add a small amount of synthesized ruthenium nanoparticle aqueous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com