Heavy-duty truck air inlet passage assembly

A technology for heavy-duty trucks and air intakes, applied in the field of air intake systems, can solve the problems of uneven air intake flow and flow rate, increased burden on air filters, and increased dust and water intake, so as to improve water removal efficiency. , Increase the water removal efficiency and dust removal effect, and reduce the resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

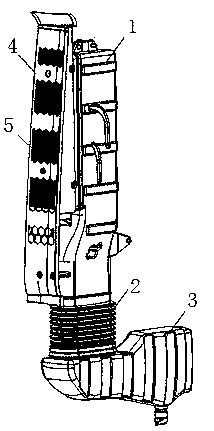

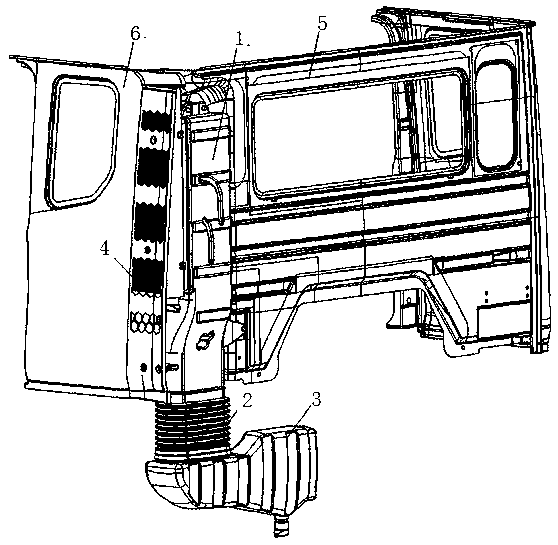

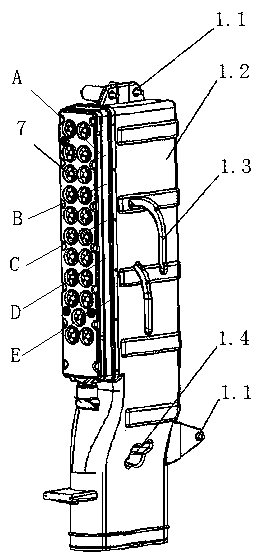

[0021] The present invention provides a heavy-duty truck air intake assembly, which includes a straight-through spiral pipe 7, an upper air intake 1, a transverse air intake 3 and an air filter, and the upper air intake 1 includes an upper air intake The channel body 1.2, the straight-through spiral tube 7 communicates with the air intake end of the upper air inlet body 1.2, and at least two groups of air intake partitions 1.3 are arranged inside the upper air inlet body 1.2, and the air intake partitions 1.3 The upper air inlet body 1.2 is divided into at least three air intake areas, and the bellows 2 is provided at the outlet end of the upper air inlet body 1.2; the horizontal air inlet 3 includes a horizontal air inlet body 3.2 and a set The guide structure 3.1 and the water dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com