A hydraulic cylinder head body self-adaptive flexible assembly equipment and hydraulic control system

A hydraulic control system and flexible assembly technology, applied in mechanical equipment, metal processing equipment, fluid pressure actuators, etc., to save time, facilitate the method, and reduce difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

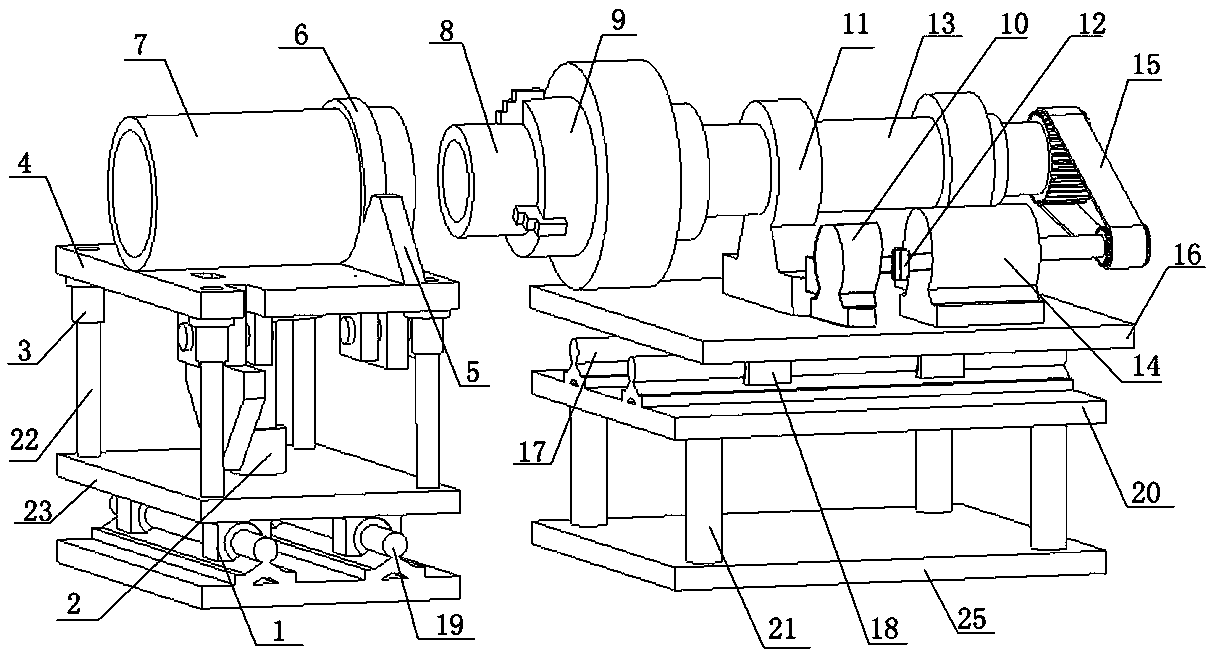

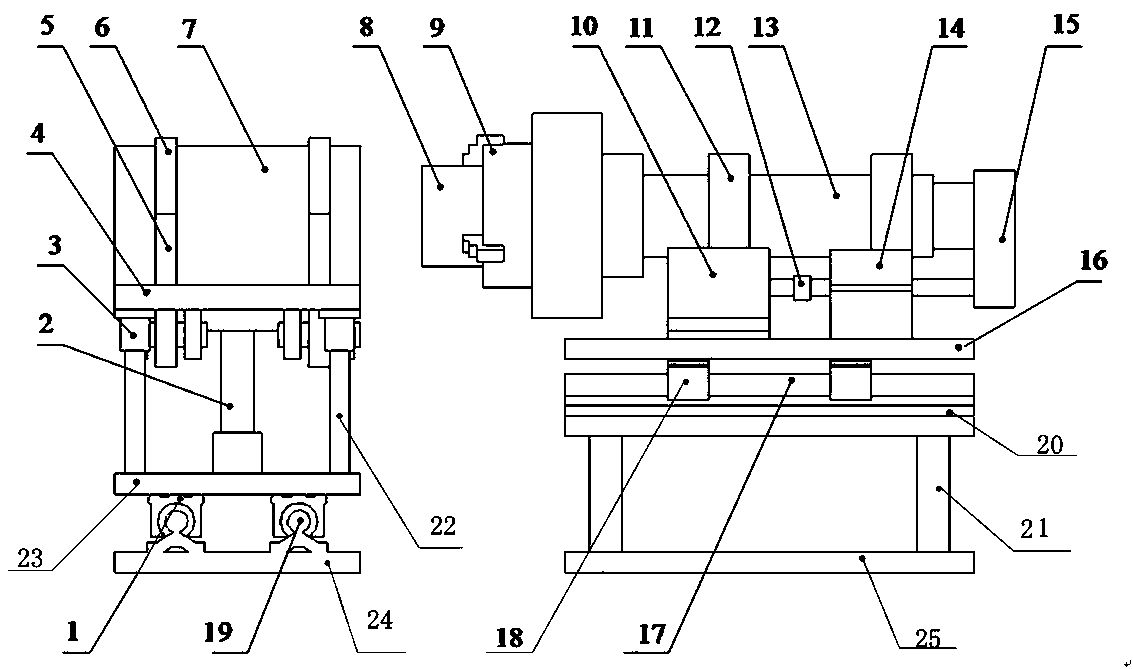

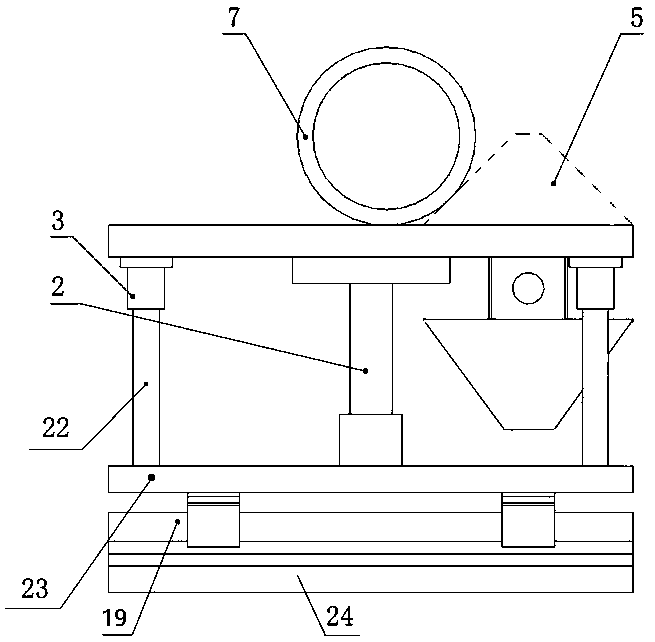

[0042] refer to Figure 1 to Figure 4 To further elaborate on the invention, a hydraulic cylinder cylinder head body self-adaptive flexible assembly equipment includes a cylinder flexible clamping platform and a cylinder head body flexible clamping platform that are independent of each other and need to be used in conjunction with each other. The cylinder flexible clamping platform is used for The cylinder 7 is fixed, and the flexible clamping platform of the cylinder can do vertical lifting movement and horizontal movement along the radial direction of the cylinder 7; the flexible clamping platform of the cylinder head body is used to fix the cylinder head body 8, and the cylinder head body is flexibly clamped The platform can move horizontally along the axis of the cylinder 7. By adjusting the flexible clamping platform of the cylinder, the axis of the cylinder 7 and the axis of the cylinder head body 8 are on the same horizontal line, and further use the flexible clamping pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com