Efficient steam generator

A steam generator and high-efficiency technology, applied in the direction of steam generation, steam generation method, steam separation device, etc., can solve the problems of decreased heating function of heating pipe, asymmetrical, affecting the use effect, etc., to improve purity and quality, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

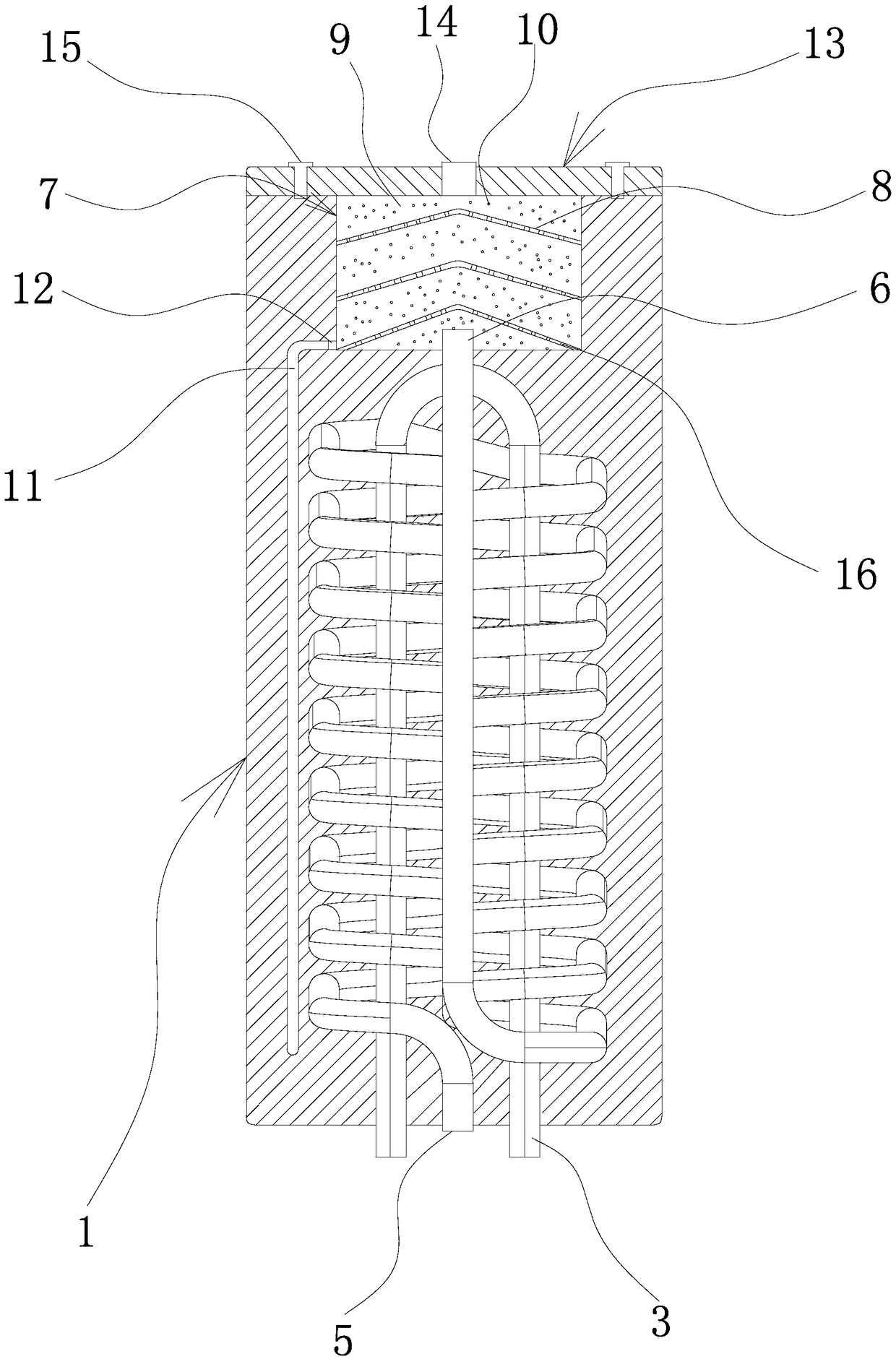

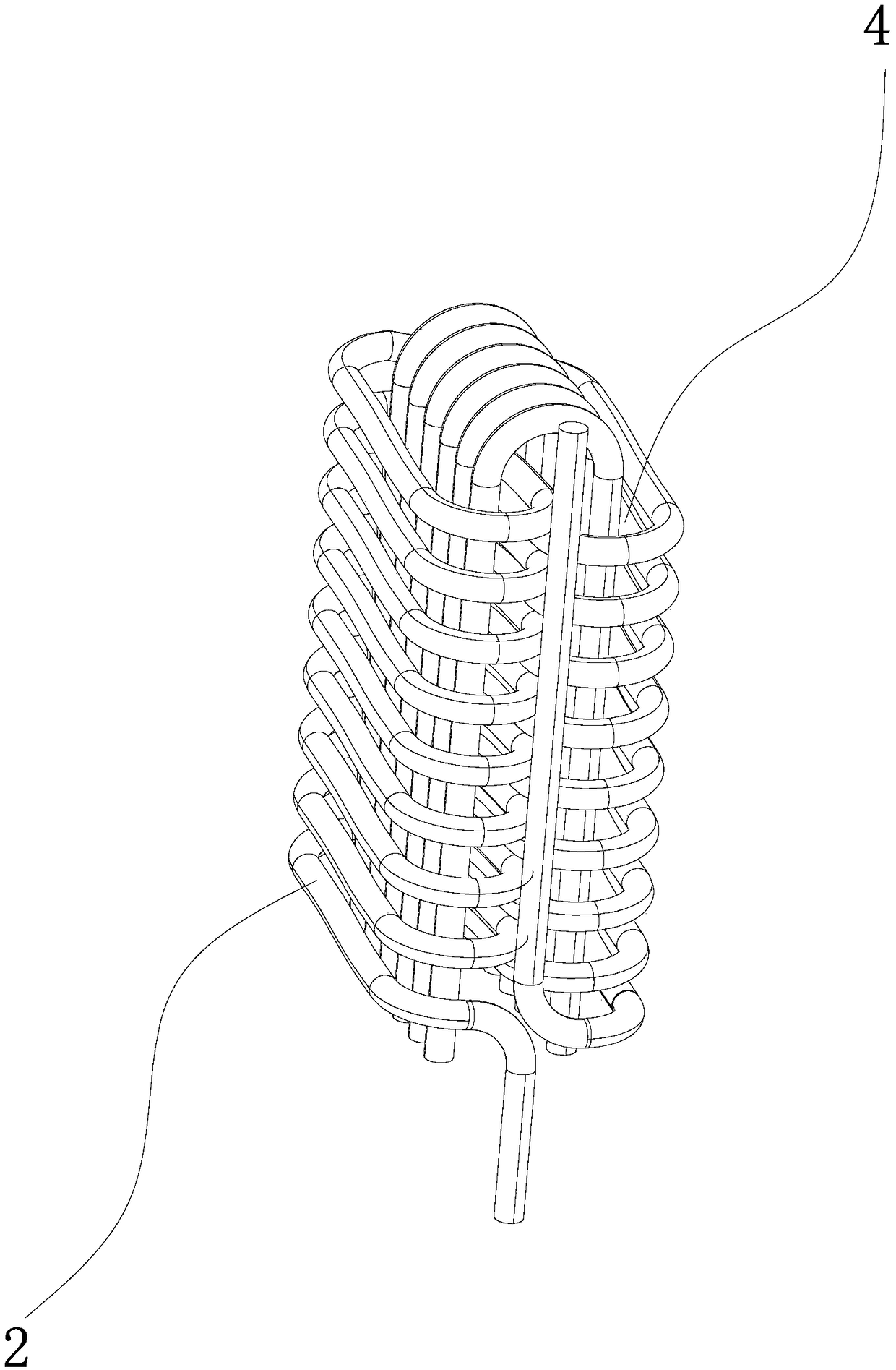

[0023] Such as figure 1 , figure 2 As shown in , the high-efficiency steam generator includes a metal shell 1, a metal spiral tube 2 and several U-shaped electric heating tubes 3. The metal spiral tube 2 is spirally wound to form two layers inside and outside, and two layers of metal spiral tubes 2 inside and outside. There is a cavity 4 separated by a radial distance from one end, and the U-shaped electric heating tubes 3 are arranged horizontally and inserted in series in the cavity 4. There is a gap between every two U-shaped electric heating tubes 3, and the U-shaped electric heating tubes 3 and The metal spiral tubes 2 are all set in the metal shell 1, the end of the U-shaped electric heating tube 3 extends out of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com