Testing device of weighing sensor

A technology of weighing sensors and testing equipment, which is applied to the detailed information of weighing equipment, instruments, weighing, etc., can solve the problems of slow testing, time-consuming and labor-intensive, etc., and achieve easy operation, reduce manpower, and easy to master Effect

Active Publication Date: 2019-01-01

台衡精密测控(昆山)股份有限公司

View PDF13 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Generally, use manual tooling to load and unload the load cell, and then manually hang the weighing weight under it or load it on the tooling scale pan, and the weighing data will be given by it. This method of testing is slow, time-consuming and labor-intensive, so How to improve test efficiency has become a technical problem urgently to be solved by those skilled in the art

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

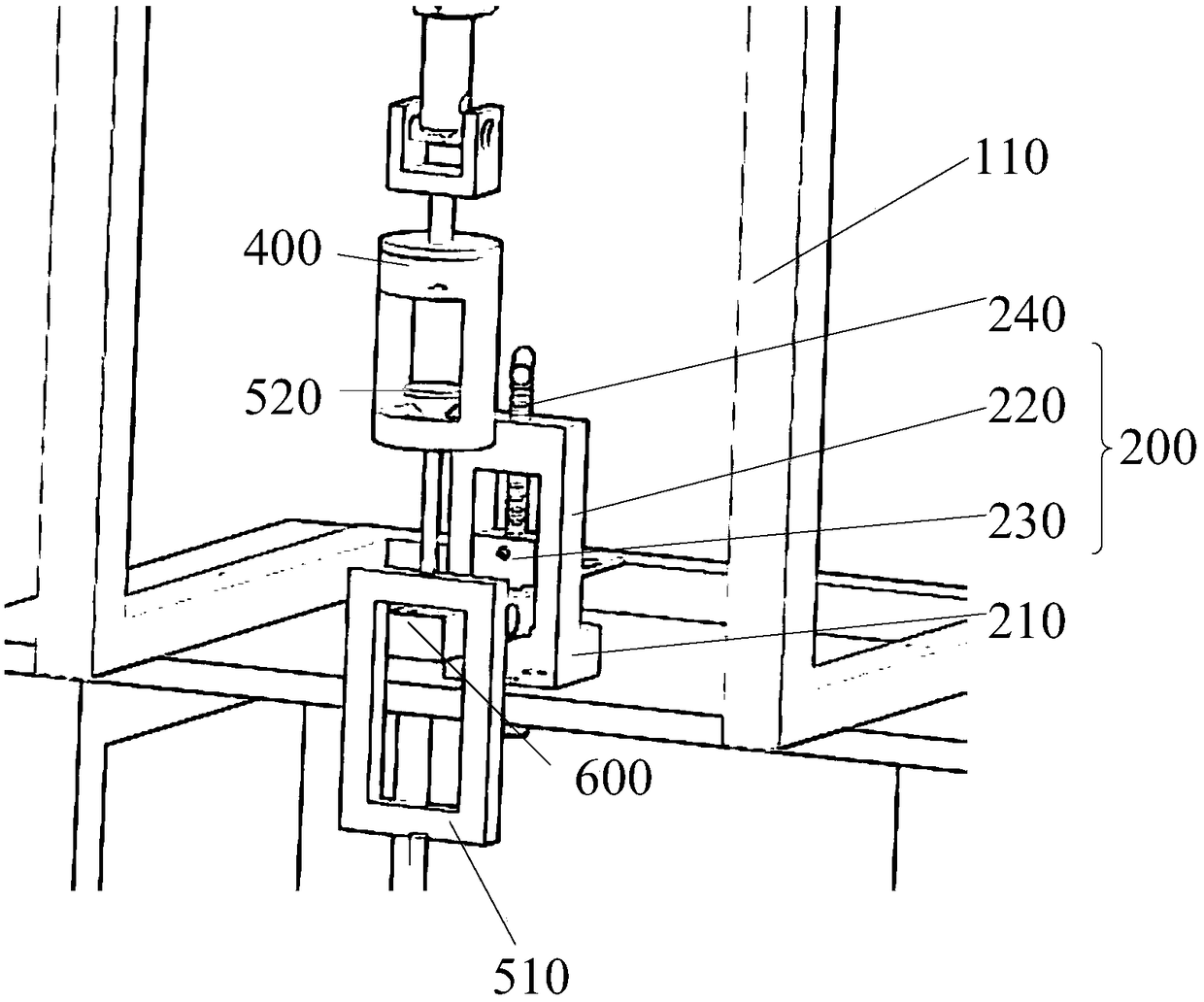

[0047] The difference between this embodiment and Embodiment 1 is that the end 520 is spherical, the inner wall of the through hole is a hemispherical hole with the largest inner diameter equal to the outer diameter of the end 520 sphere, and the diameter of the opening at the bottom of the through hole is greater than or equal to the end 520 and the outer diameter of the metal rod between the closed frame 510.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

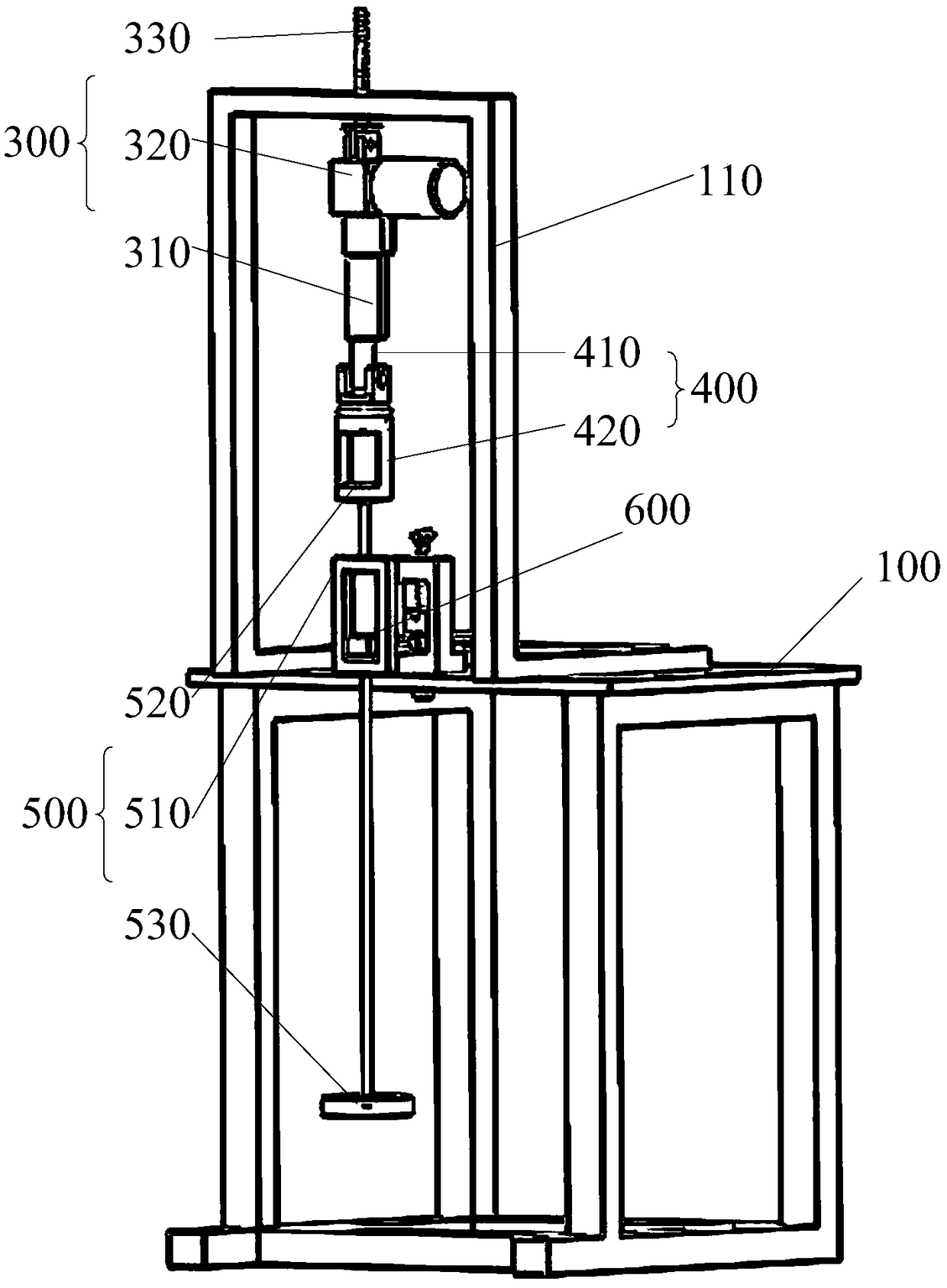

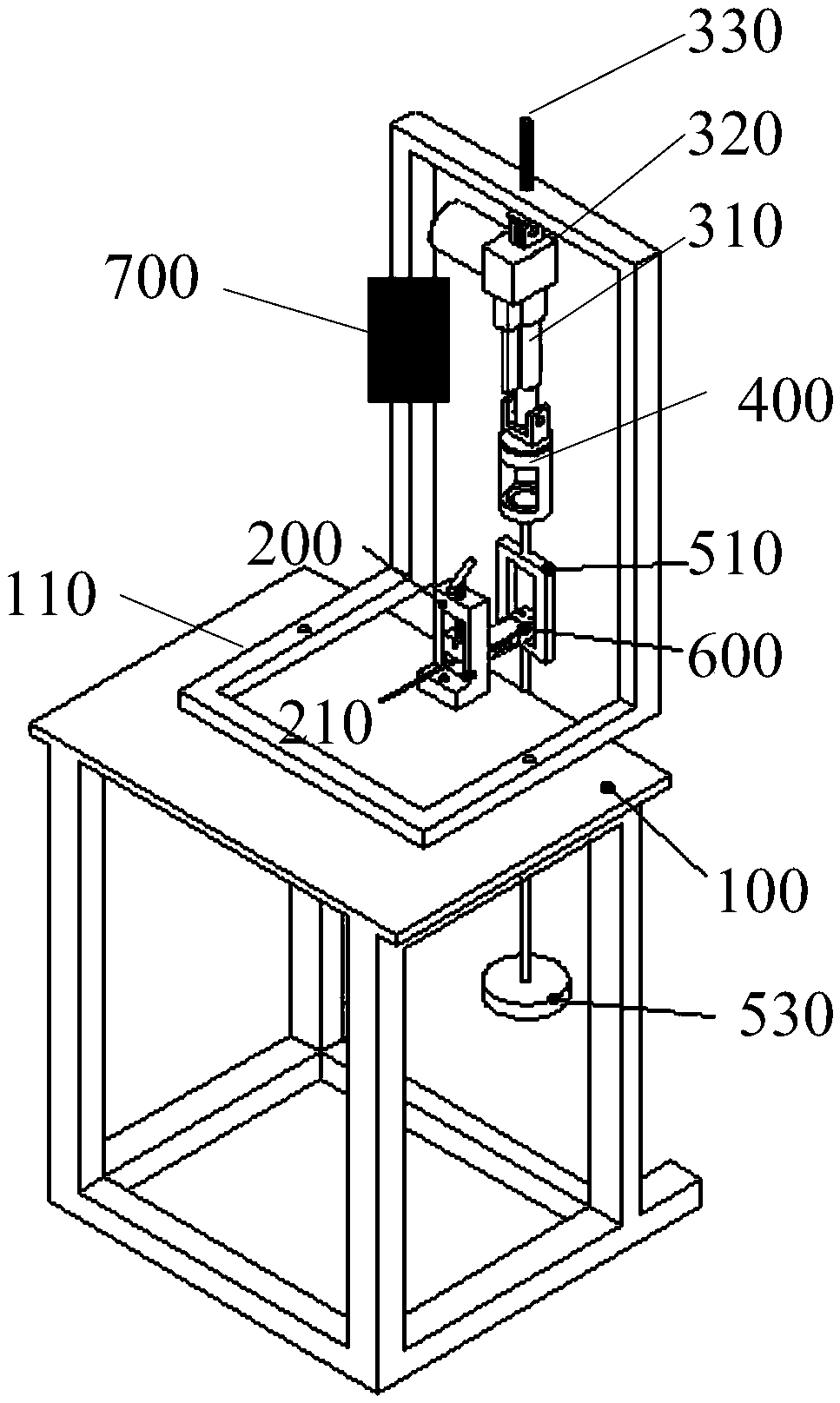

The invention provides a testing device of a weighing sensor. The testing device comprises a device bench, a loading and unloading device, a suspender device, and a lifting device. The loading and unloading device fixed on the top board of the device bench is used for fixing a weighing sensor. A closed frame is formed at the upper end of the suspender device and a weight placing plate is arrangedat the lower end of the suspender device; and one end of the weighing sensor is arranged in the closed frame and the other end of the weighing sensor is fixed in the loading and unloading device. Thelifting device is connected with the suspender device detachably. During the testing time, the lifting device enables the suspender device to descend and thus the top of the closed frame is in contactwith the weighing sensor; and then the weighing sensor carries the suspender device independently. Therefore, a problem of the testing efficiency of the weighing sensor is solved. The manpower is reduced, the machine size is reduced, the manufacturing cost is lowered, and no noise is caused in operation. The weighing sensor uses the loading and unloading device to realize quick loading and unloading; either a male worker or a female worker can carry out operation; the testing device is easy to operate; and the testing efficiency is improved substantially.

Description

technical field [0001] The invention relates to the field of production testing of weighing sensors, in particular to a testing device for weighing sensors. Background technique [0002] There are many kinds of sensors at present, and the load cell is one of them. In order to ensure the accuracy of its weighing, each load cell must undergo a weighing test before leaving the factory. Generally, use manual tooling to load and unload the load cell, and then manually hang the weighing weight under it or load it on the tooling scale pan, and the weighing data will be given by it. This method of testing is slow, time-consuming and labor-intensive, so How to improve testing efficiency has become a technical problem to be solved urgently by those skilled in the art. Contents of the invention [0003] The invention provides a weighing sensor testing device, which only needs to manually load the weighing sensor, and the rest is completed by machine testing, thereby solving the abov...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01G1/02G01G1/04G01G21/00

CPCG01G1/02G01G1/04G01G21/00

Inventor 吴永鹏林颖俊傅羿扬苏厚胜

Owner 台衡精密测控(昆山)股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com