Capacitive flexible pressure sensor and preparation method thereof

A pressure sensor and capacitive technology, applied in the field of capacitive flexible pressure sensor and its preparation, can solve the problems of high cost, inability to bend sensitivity, etc., and achieve the effects of high sensitivity, increased sensitivity, and easy arraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

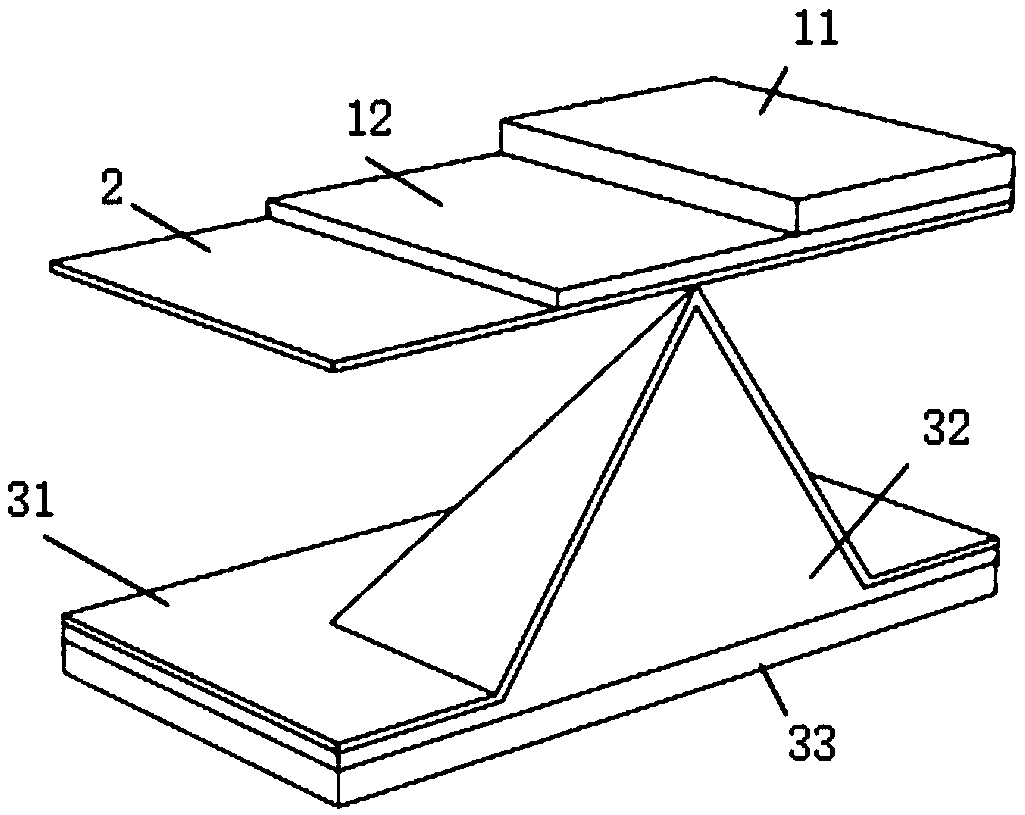

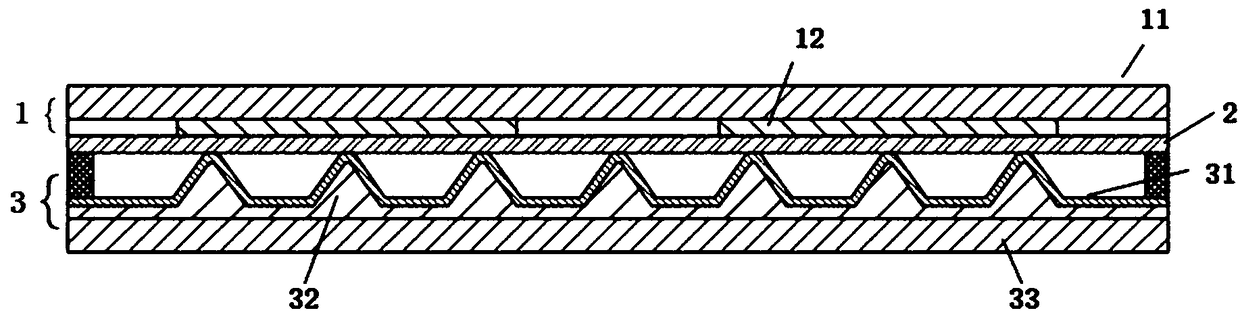

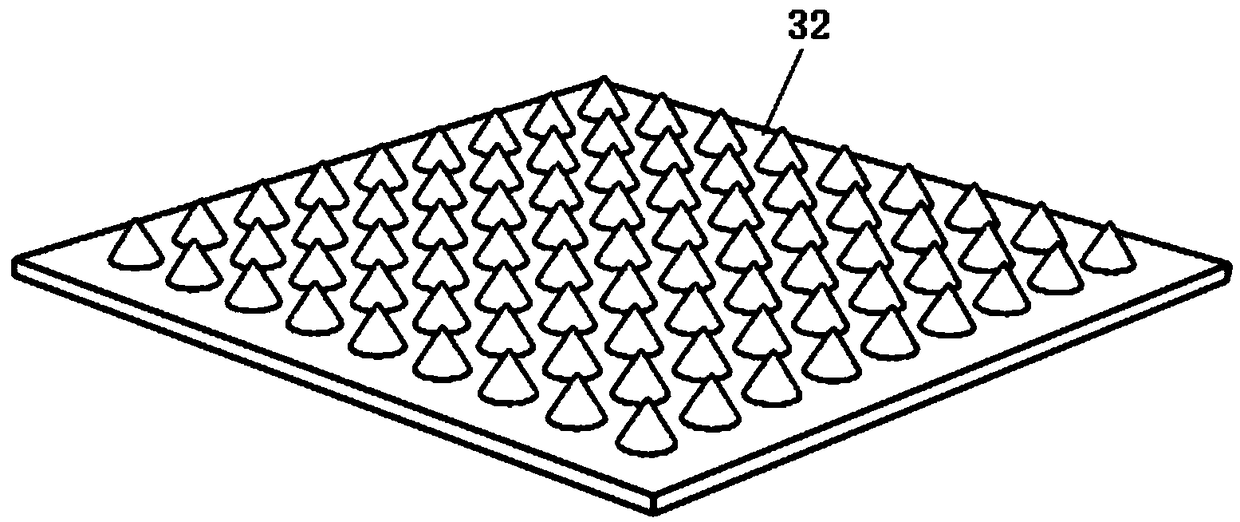

[0030] refer to Figure 1 to Figure 4 , in one embodiment, a capacitive flexible pressure sensor comprises an ITO electrode plate 1, an insulating film 2 and a polymer elastomer electrode 3; the polymer elastomer electrode 3 comprises a conductive film 31, a polymer elastic body 32 and an electrode substrate 33, the polymer elastomer 32 includes a microstructure layer with a microstructure protrusion array formed on the electrode substrate 33, the conductive film 31 is evenly coated on the microstructure The surface of the layer; the insulating layer film 2 is placed between the polymer elastomer electrode 3 and the ITO electrode plate, and is in contact with the top of the microstructure protrusion of the microstructure layer through the conductive fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com