A control method for slow cooling of strip steel in heat treatment furnace

A slow and strip technology, applied in the control field of slow cooling of strip in heat treatment furnace, can solve the problems of large temperature difference of exit strip, reducing output power of fan and electric heating, wasting energy and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

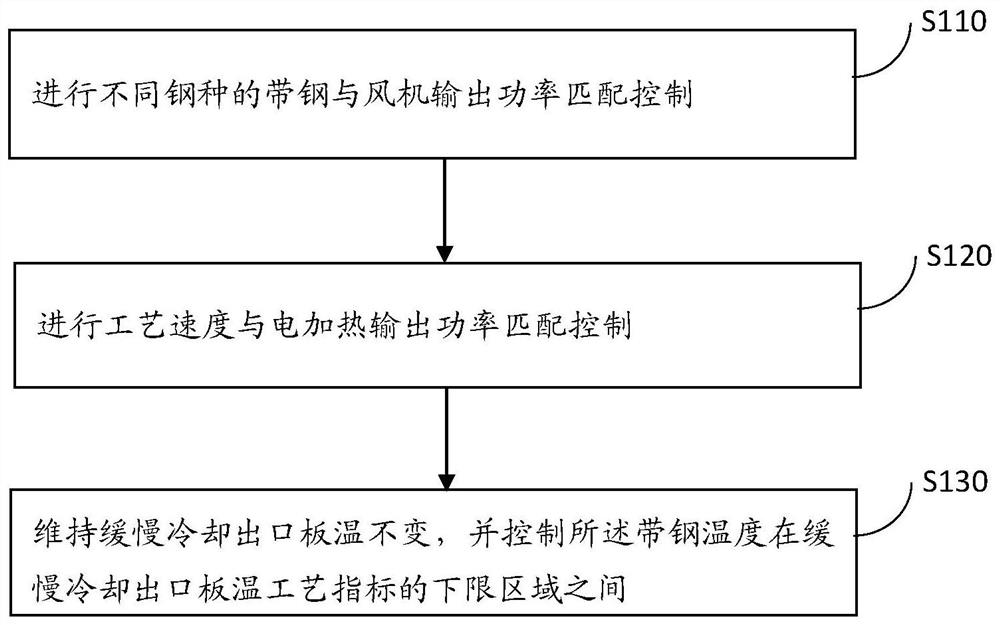

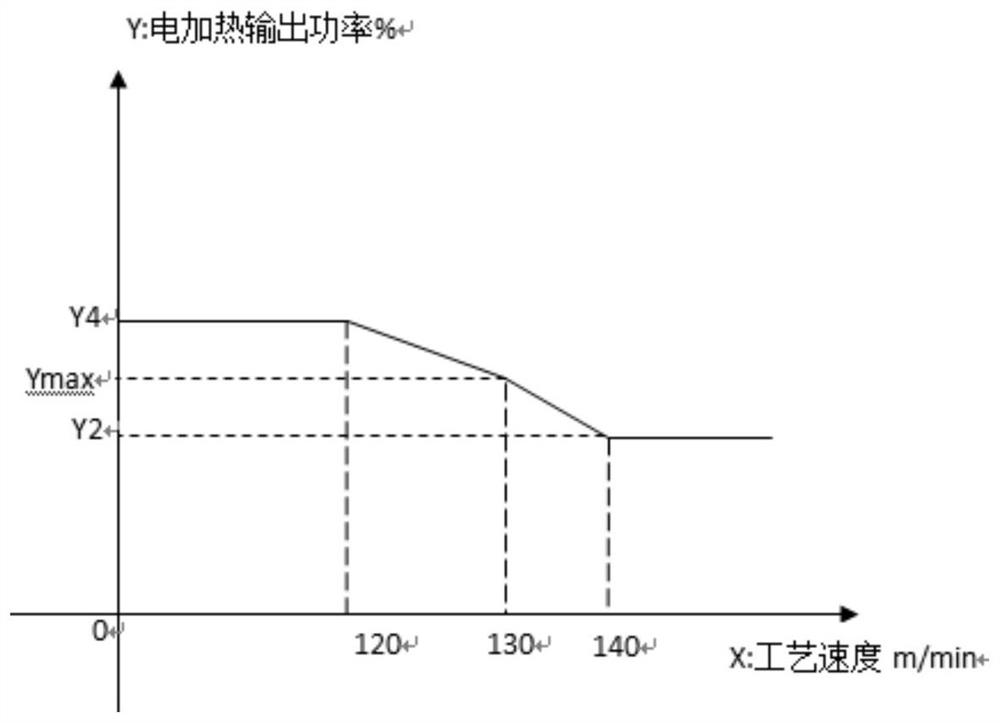

[0022] The embodiment of the present invention provides a method for controlling the slow cooling of the steel strip in the heat treatment furnace, please refer to Fig. 1 to image 3 , under the premise of slow cooling temperature control, the method comprises:

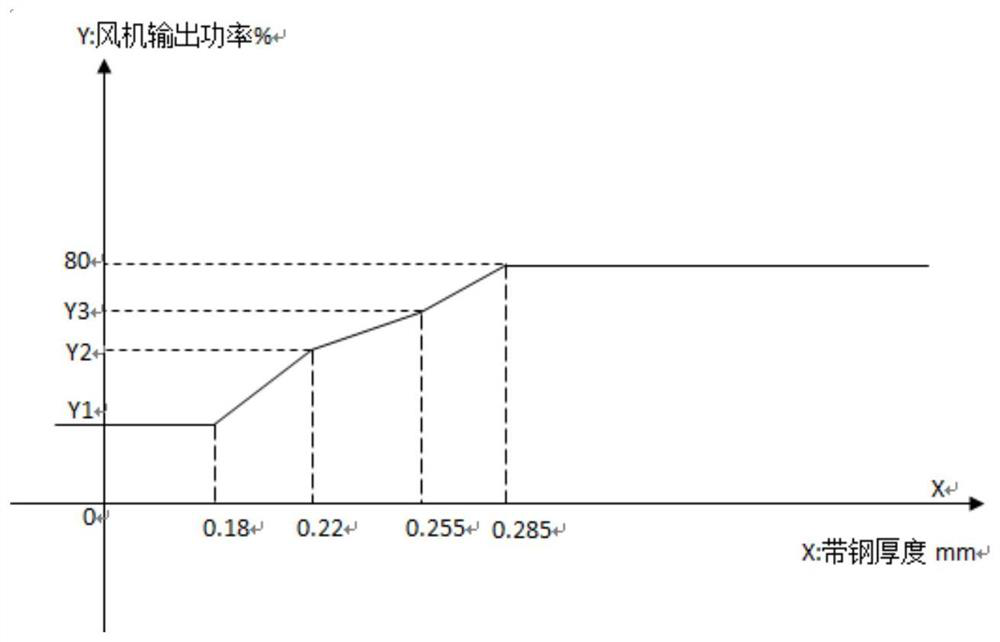

[0023] Step S110: Carry out the matching control of the strip steel of different steel types and the fan output power;

[0024] Further, the matching control of different steel types and fan output power includes: according to the thickness of the strip, lowering the output power of the fan, reducing the cooling capacity, so that the temperature of the strip steel is in the upper limit area of the slow cooling outlet plate temperature process index Between; the upper limit area of the slow cooling exit plate temperature process index is 600-620 °C.

[0025] Further, after the temperature of the strip steel is between the temperature of the slow cooling exit plate and the upper limit range, it includes: reducing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com