Distribution line clamping traveling inspection robot device

A technology of power distribution lines and robots, which is applied in the direction of overhead lines/cable equipment, manipulators, manufacturing tools, etc. It can solve the problems of unusable cables, large devices, and power failure cooperation, etc., and achieves small size and ensures stable recovery. , Improve the effect of standby time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

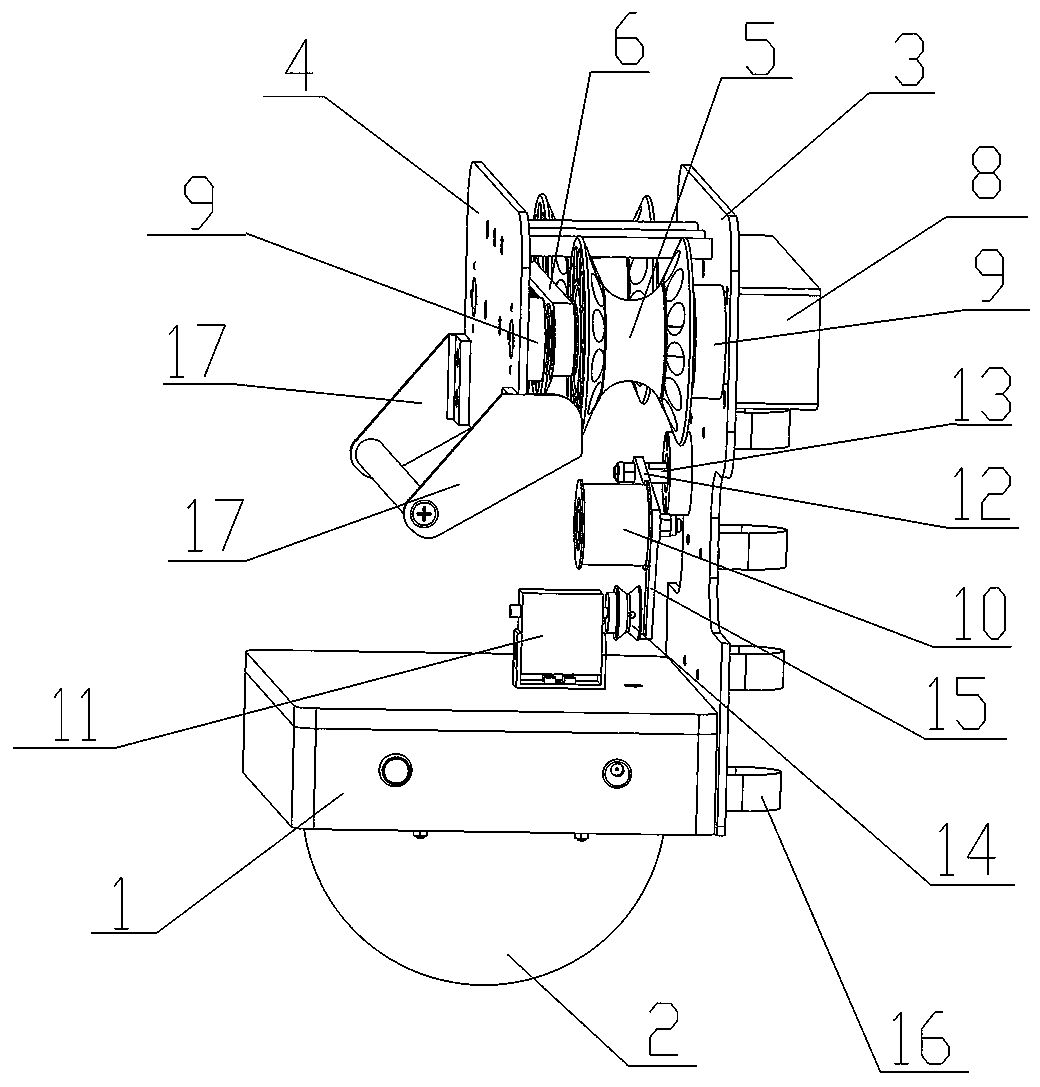

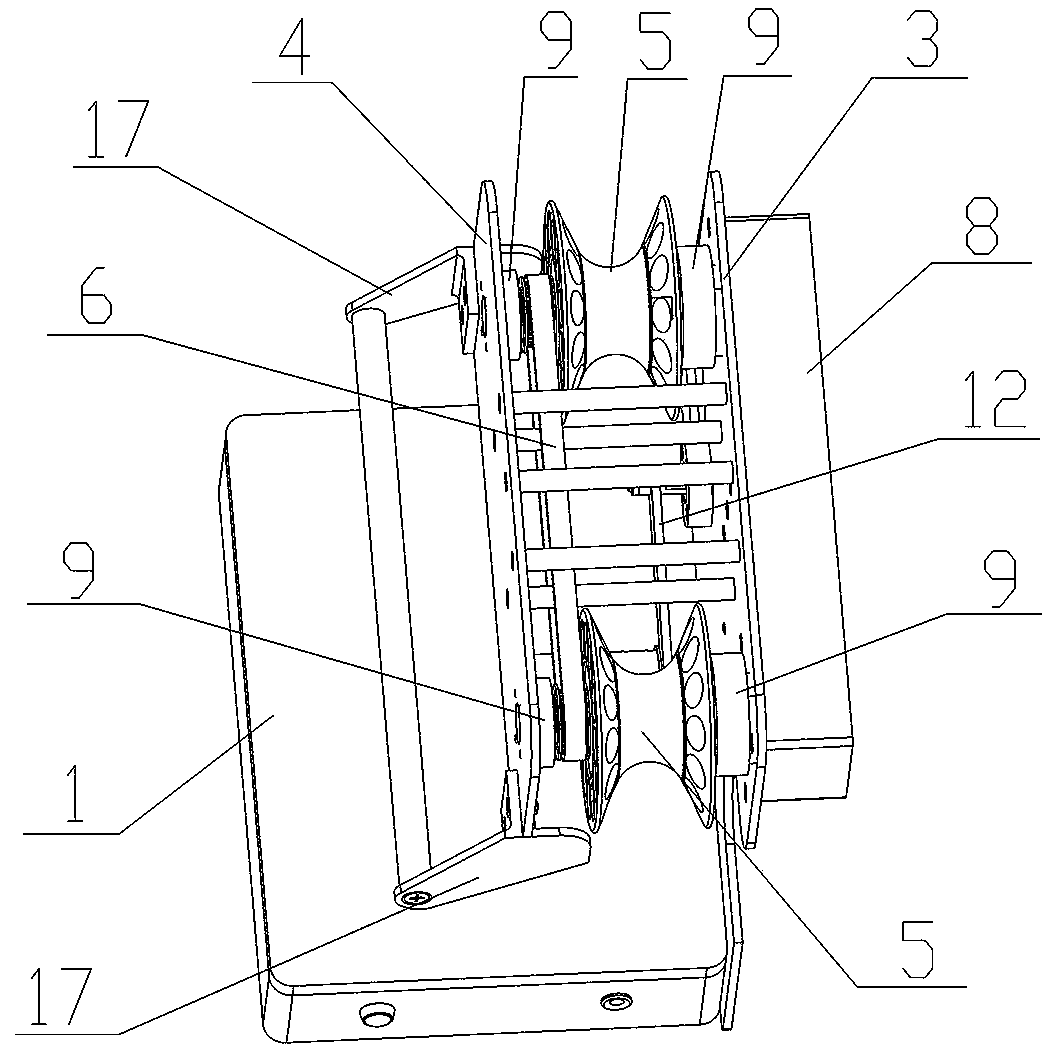

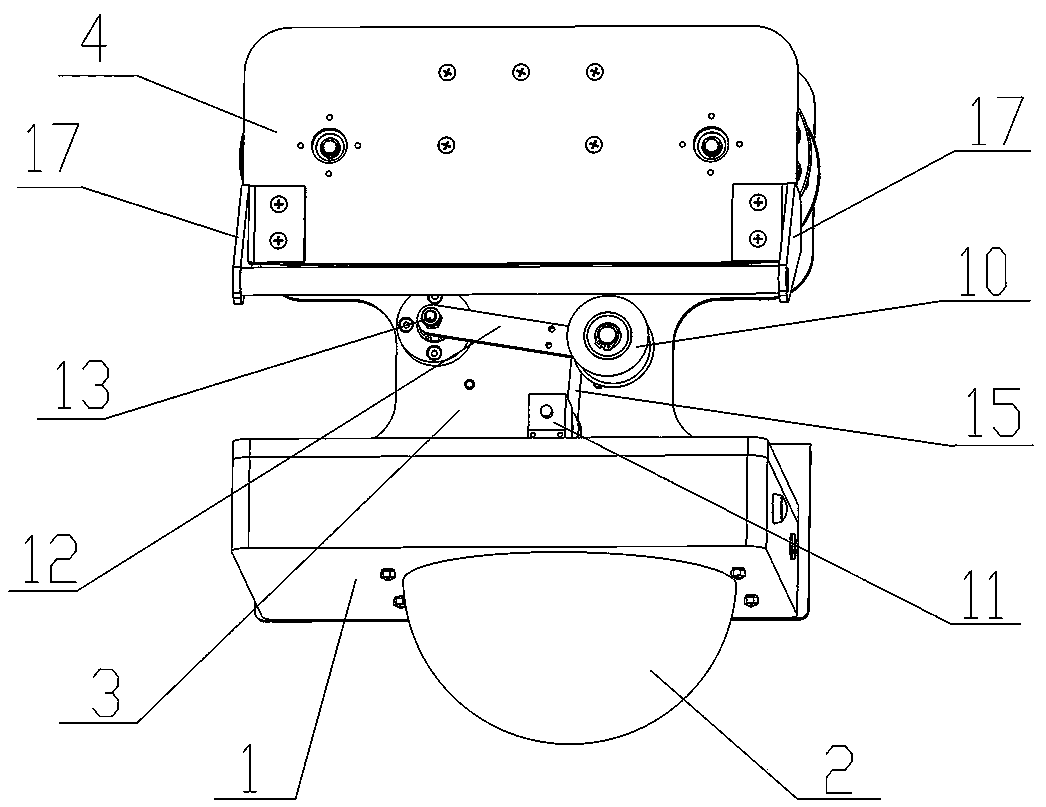

[0030] Such as figure 1 -As shown in -5, a distribution line clamping walking type inspection robot device includes a mounting plate, a traveling mechanism, a compacting mechanism that cooperates with the traveling mechanism to compress the cables, and a control box 1 for driving the traveling mechanism and the compacting mechanism , the walking mechanism and the pressing mechanism are located on the mounting plate, the mounting plate includes a first mounting plate 3 and a second mounting plate 4 which are arranged oppositely, and a plurality of horizontally arranged support frames are arranged between the two mounting plates for connection, and the walking The mechanism is located between the two mounting plates, and the pressing mechanism is located at the bottom of the inner side of the first mounting plate 3, and is located below the traveling mechanism to cooperate with the traveling mechanism to compress the cables.

[0031] The running mechanism includes two road wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com