Semi-feeding type combined rice harvester

A harvester and paddy technology, applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve problems such as sorting threshing, technical solution limitations, rice dust not cleaned, etc., to speed up threshing, improve threshing effect, and improve cleanliness degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

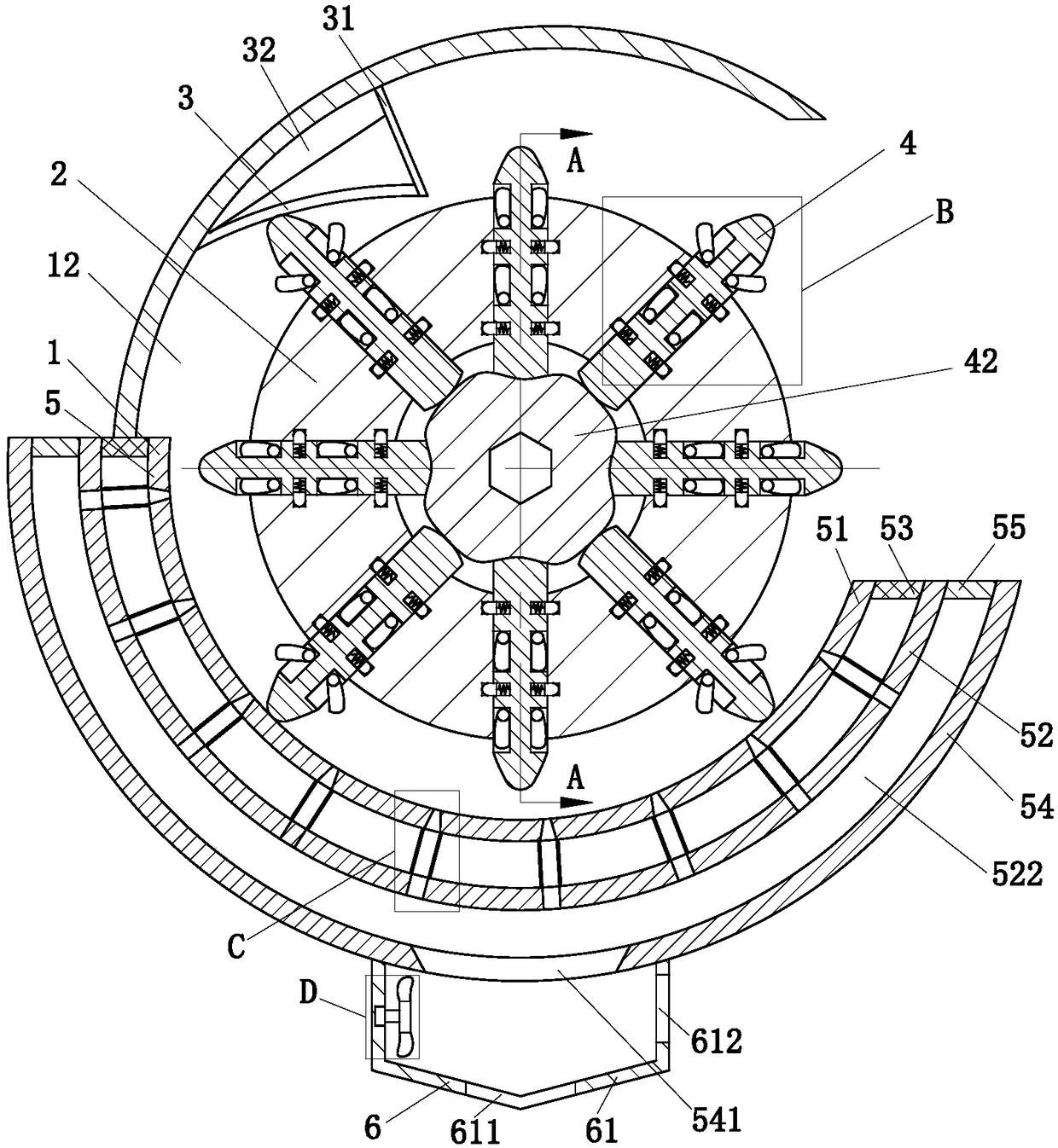

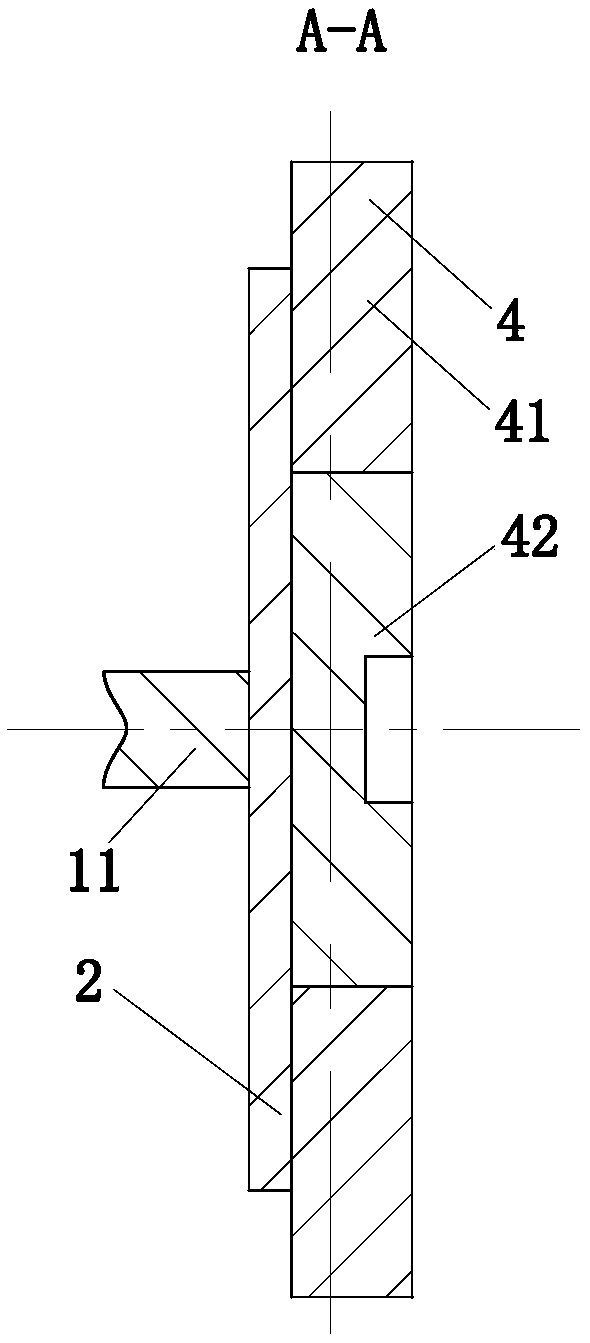

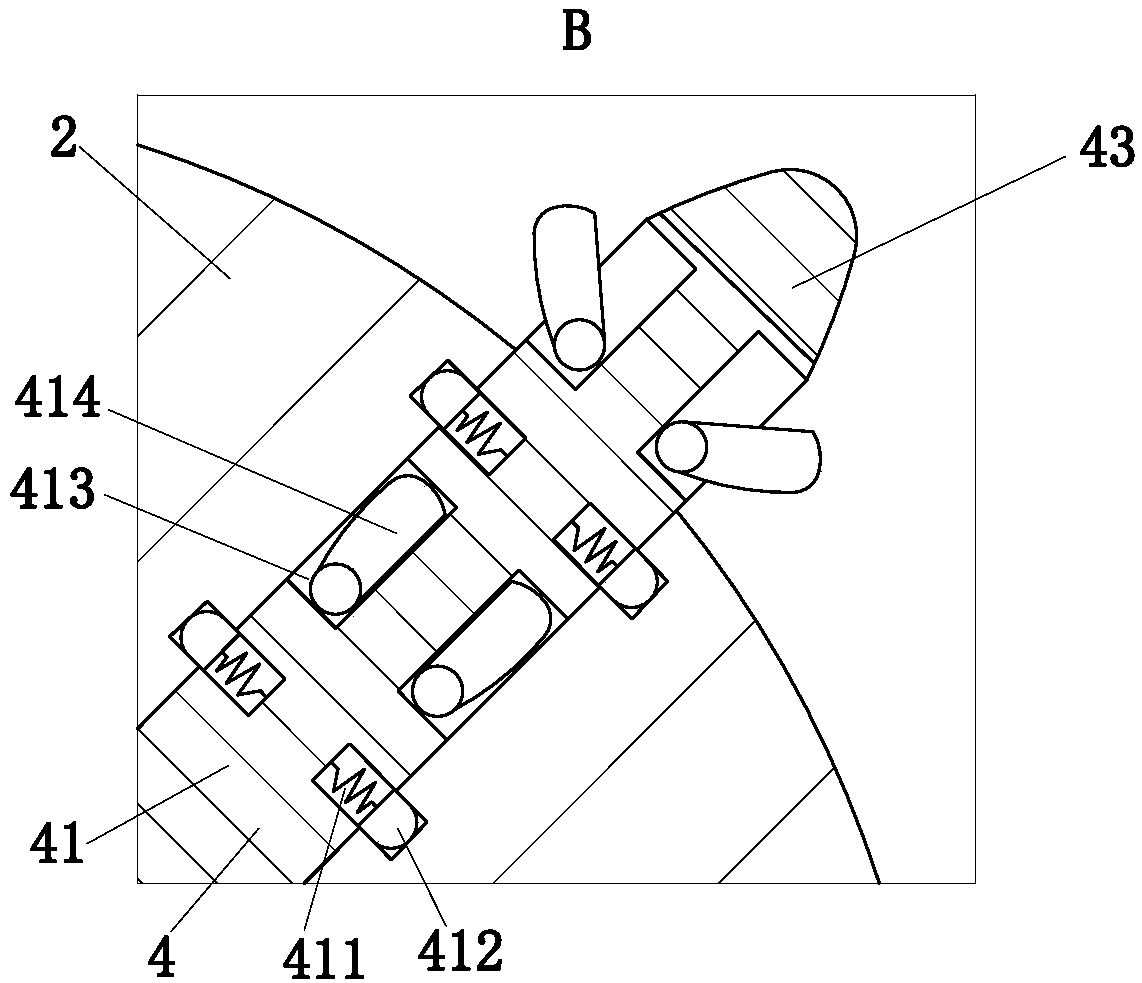

[0028] As an embodiment of the present invention, a threshing unit 5 is provided at the lower left end of the threshing chamber 1; the threshing unit 5 is used for threshing rice, and the threshing unit 5 includes a No. 52. Sleeve 53, No. 3 arc-shaped plate 54, connecting plate 55 and No. 1 pipe 56; the No. 1 arc-shaped plate 51 is located above the No. 2 arc-shaped plate 52; the No. 2 arc-shaped plate 52 is located on No. 3 Above the arc plate 54; the sleeve 53 is used to seal the first arc plate 51 and the second arc plate 52; the connecting plate 55 is used to connect the second arc plate 52 and the third arc plate 54; The No. 1 arc-shaped plate 51 is provided with a group of No. 1 holes 511; the No. 2 arc-shaped plate 52 is provided with a group of No. 2 holes 521; the No. 3 arc-shaped plate 54 is provided with No. 3 holes; The No. 2 hole 521 communicates with the No. 1 hole 511 through the No. 1 pipe 56 ; the rice concentration area 522 is formed between the No. 2 arc-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com