A multifunctional food processor

A food processing machine and multi-functional technology, applied in the field of food processing, can solve the problems that a single cup body cannot make hot drinks and vacuum at the same time, is not intelligent enough, and is prone to errors, etc., and achieves the effect of reducing foam, facilitating freshness preservation, and avoiding ineffective work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

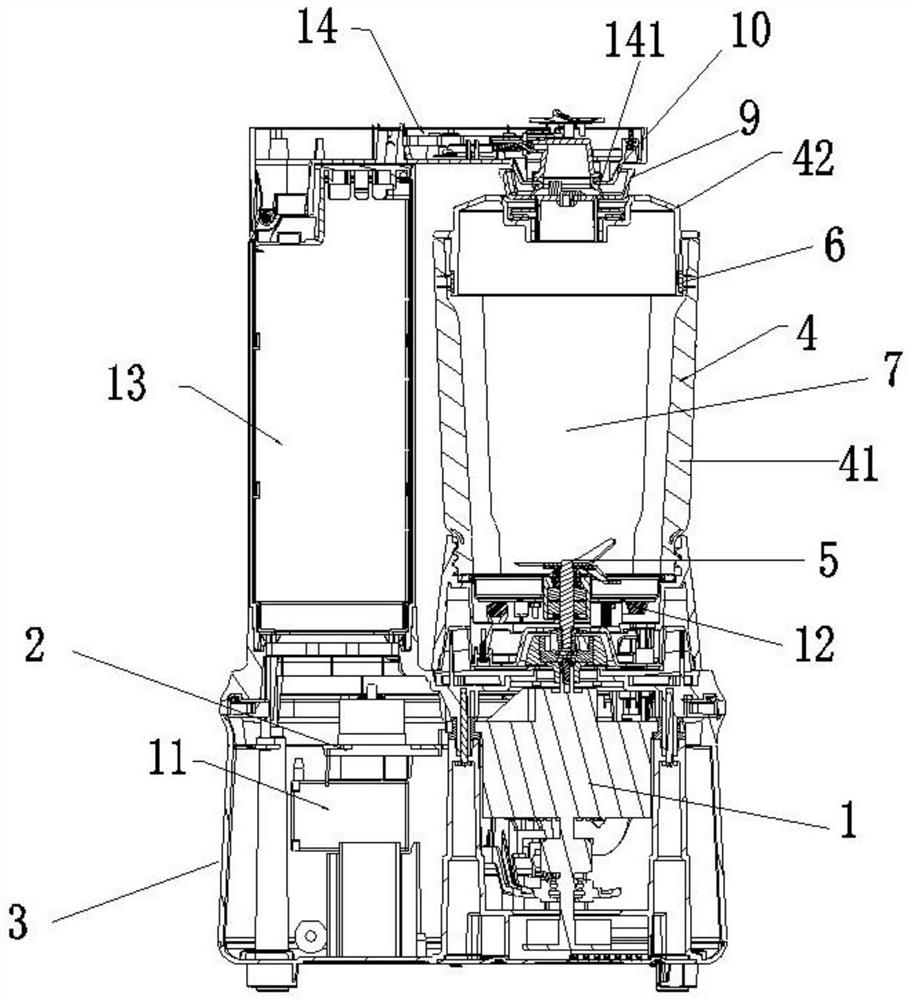

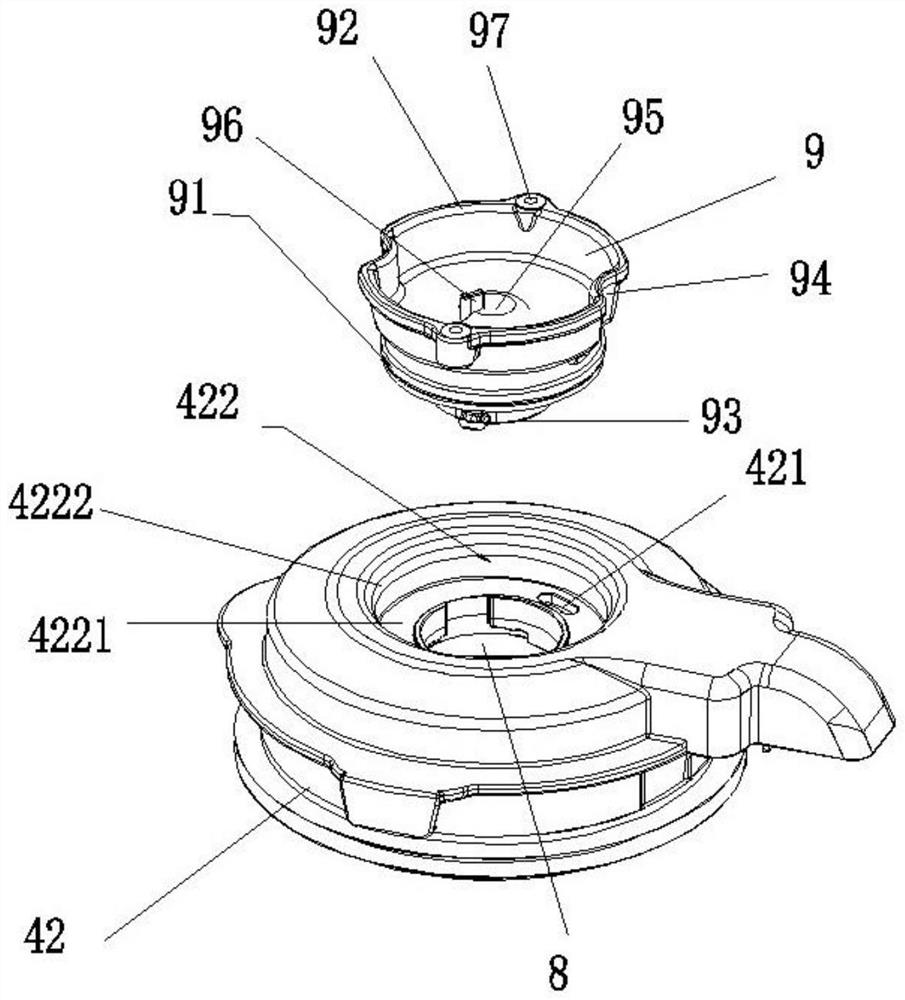

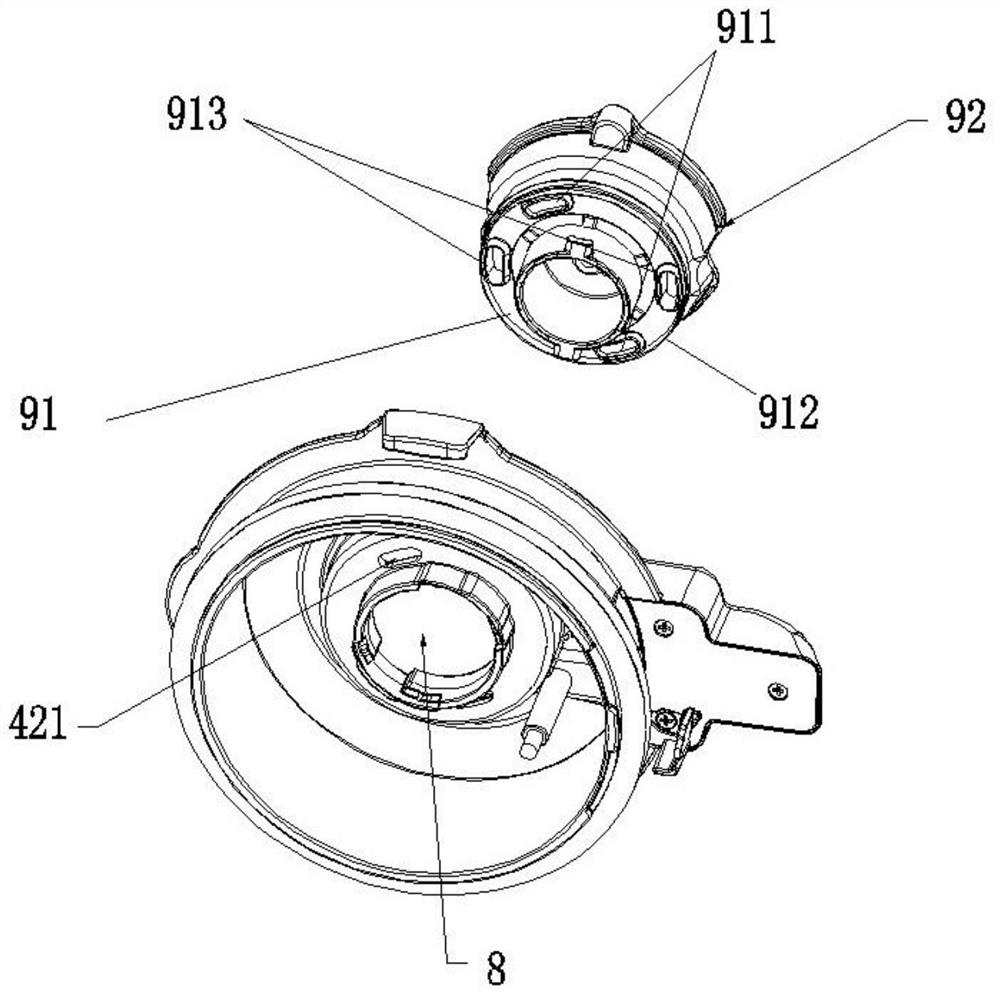

[0034] Such as Figure 1-3As mentioned above, the present invention provides a multifunctional food processor, which includes a base 3 with a motor 1 and a control board 2, a stirring cup 4 connected to the base 3, and a crushing knife 5 arranged in the stirring cup 4. The stirring cup 4 includes a cup body 41 and a cup cover 42. The cup cover 42 is sealed on the upper end of the cup body. The inner wall of the port is fitted together to realize the sealing between the cup cover 42 and the cup body. The cup cover 42 and the cup body form a crushing space 7, and the motor 1 drives the crushing knife 5 to rotate, wherein the cup cover 42 There is a feeding port 8 on the top, and the feeding port 8 is provided with a relatively rotatable feeding cover 9. When the feeding cover 9 rotates to the first position, the crushing space 7 communicates with the outside world, and the feeding cover 9 rotates to the second position. position, the crushing space 7 is separated from the outsi...

Embodiment 2

[0053] Such as Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that the air outlet 421 is arranged on the side wall of the annular sinker 422, the air vent 911 is arranged on the side wall of the feeding cover 9, and the air outlet 421 and the air outlet 911 The positions are equivalent, and a sealing ring is provided between the feeding cover 9 and the annular sinking platform 422 below the vent hole 911 to realize surface-to-face sealing, ensuring that gas can only be discharged to the outside world after passing through the vent hole 421 and the vent hole 911. The advantage of this arrangement is that the sealing and opening effect of the first embodiment can also be achieved by changing the upper and lower penetrations in the first embodiment to the left and right penetrations.

Embodiment 3

[0055] Such as Figure 9 As shown, the difference between this embodiment and Embodiment 1 is that: the air outlet 421 is provided on the top of the cup cover 42, and is arranged vertically through, and the gripping portion 92 of the feeding cover 9 includes an extension plate 15, which is arranged There is a gap on the air outlet 421, and the lower surface of the extension plate is provided with a downwardly protruding sealing column 16. The sealing column is made of silica gel. When it is rotated to the first position, the air outlet 421 is directly connected to the atmosphere. When rotating to the second position, the sealing column just seals the air outlet 421 to achieve sealing. This setting can also replace the sealing method in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com