A device for filtering fiber suspensions

A technology for filtering fibers and suspensions. It is used in devices for filtering fiber suspensions and in the field of suspensions that are difficult to dehydrate. It can solve problems such as increased distance, adhesion, and expensive structures, and achieve less operational interference, service requirements, and production capacity. High and good effect of process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

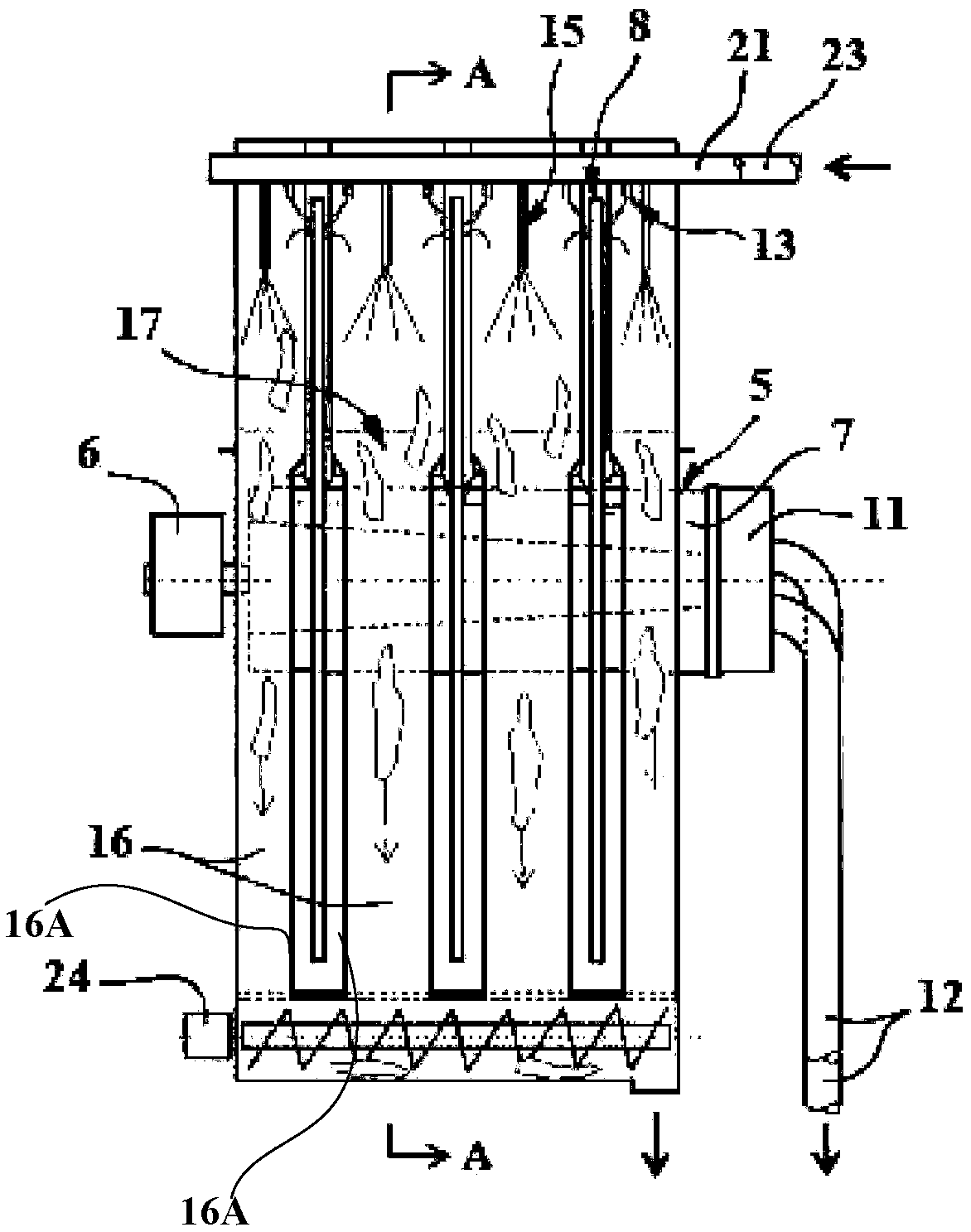

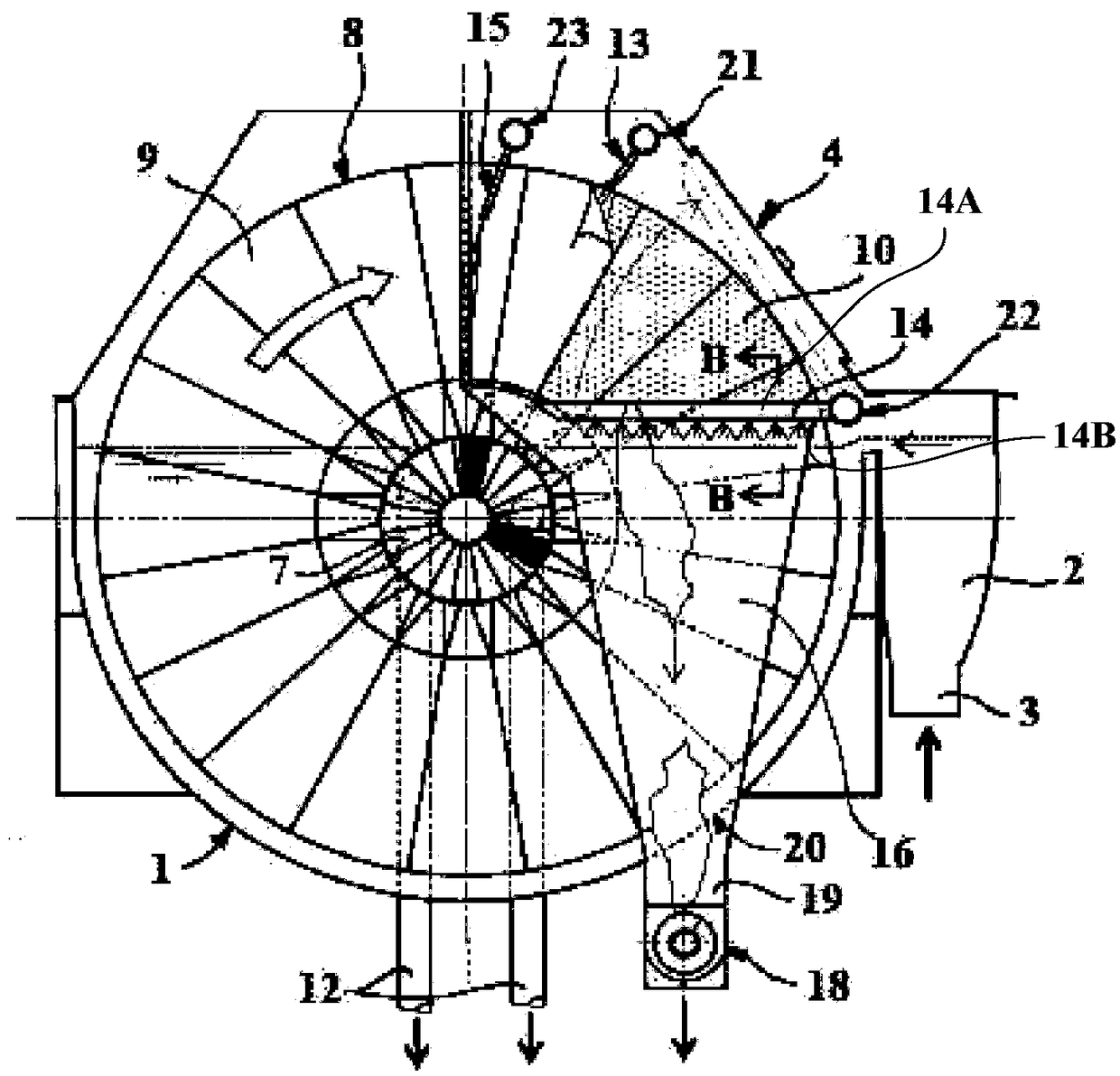

[0040] In the following, a filter device according to the invention which is suitable for dewatering and thickening a fiber suspension which is relatively easy to dewater will be described, but which is also advantageously used for a suspension which is difficult to dewater.

[0041]The filtering device consists of a U-shaped cylinder with a triangular and supporting structure, marked 1, and an inlet 2 for the fiber suspension. The inlet 2 is provided along one side of the cylinder 1 . Inlet tube marked 3 leads to inlet 2. The upper part of the cylinder is sealed with one or more hatches 4 which can be opened.

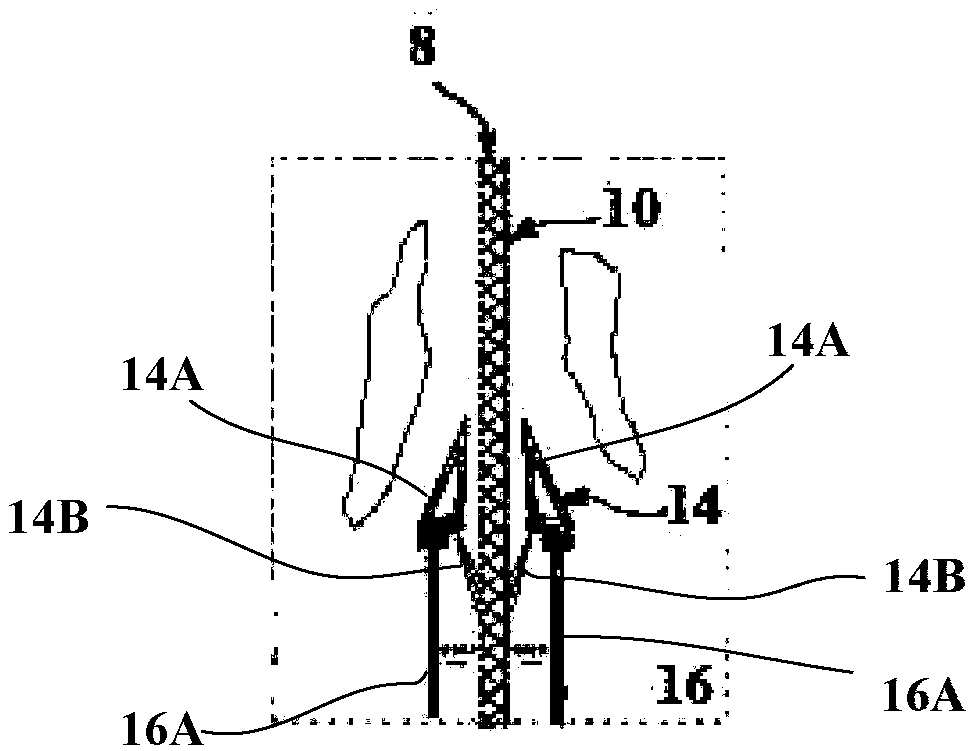

[0042] In the cylinder 1 there is provided an inner rotatable shaft 5 with an actuator 6 , a fluid channel 7 and a plurality of outer disc-shaped filter elements 8 placed across the geometric axis of the inner shaft 5 . The disc-shaped filter element 8 is oriented substantially perpendicular to the axis of rotation of the shaft 5 . Each disc-shaped filter element 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com