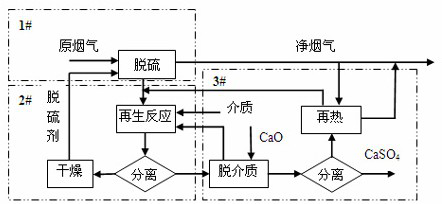

A double-alkali flue gas desulfurization process

A desulfurization process and dual-alkali process technology, applied in the field of flue gas/waste gas treatment, can solve the problems of difficulty in operation and maintenance, poor regeneration effect, reduction of flue gas temperature, etc., achieve full conversion and utilization of materials, and overcome the significant reduction of flue gas temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] For flue gas desulfurization of a coke oven, the initial inlet flue gas temperature is 170-180°C, SO 2 Concentration 120mg / Nm 3 about.

[0033] The flue gas desulfurization unit of the process system adopts spray drying technology and equipment: using sodium bicarbonate as absorbent, first mix it with water in the slurry mixing tank to form a slurry with a mass fraction of about 20%, and then spray it into the absorption tower through a sprayer. The absorption tower is in full contact with the hot flue gas (residence time is about 1.5 seconds), and the SO in it is removed 2 , to generate a dry powder product, the main components are sodium sulfate, a small amount of sodium carbonate and a small amount of sodium sulfite, which are collected by the bag filter after entering the absorption tower.

[0034] Desulfurization agent regeneration unit of the process system: 100kg of the reaction product taken out of the bag filter of the above desulfurization unit is mixed with...

Embodiment 2

[0038] A coal-fired boiler flue gas purification project, the initial inlet flue gas temperature is 150-165°C, SO 2 Concentration 400mg / Nm 3 .

[0039] Flue gas desulfurization unit: adopt dry process and equipment, use solid sodium bicarbonate as absorbent, first grind and sieve sodium bicarbonate, and then spray it into the flue reactor with the help of fluidized wind according to the reaction metering ratio, and mix with hot flue gas Full contact, the reaction removes SO 2 , to generate sodium sulfate and a small amount of sodium carbonate product, which is dry powder and is collected by the bag filter.

[0040] Desulfurization agent regeneration unit: 20kg of the reaction product taken out of the bag filter of the above desulfurization unit is mixed with water to make a slurry with a mass concentration of about 30%, inject it into the regeneration reaction device, mix and add 26kg of regeneration medium (ammonium bicarbonate) and stir for reaction together About 1h, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com