Soft claw mandrel adjuster

A technology of adjusters and mandrels, applied in the direction of manufacturing tools, chucks, metal processing machinery parts, etc., can solve the problems of lower production efficiency, 6S management and customization management troubles, and achieve the effect of solving management and facilitating boring processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

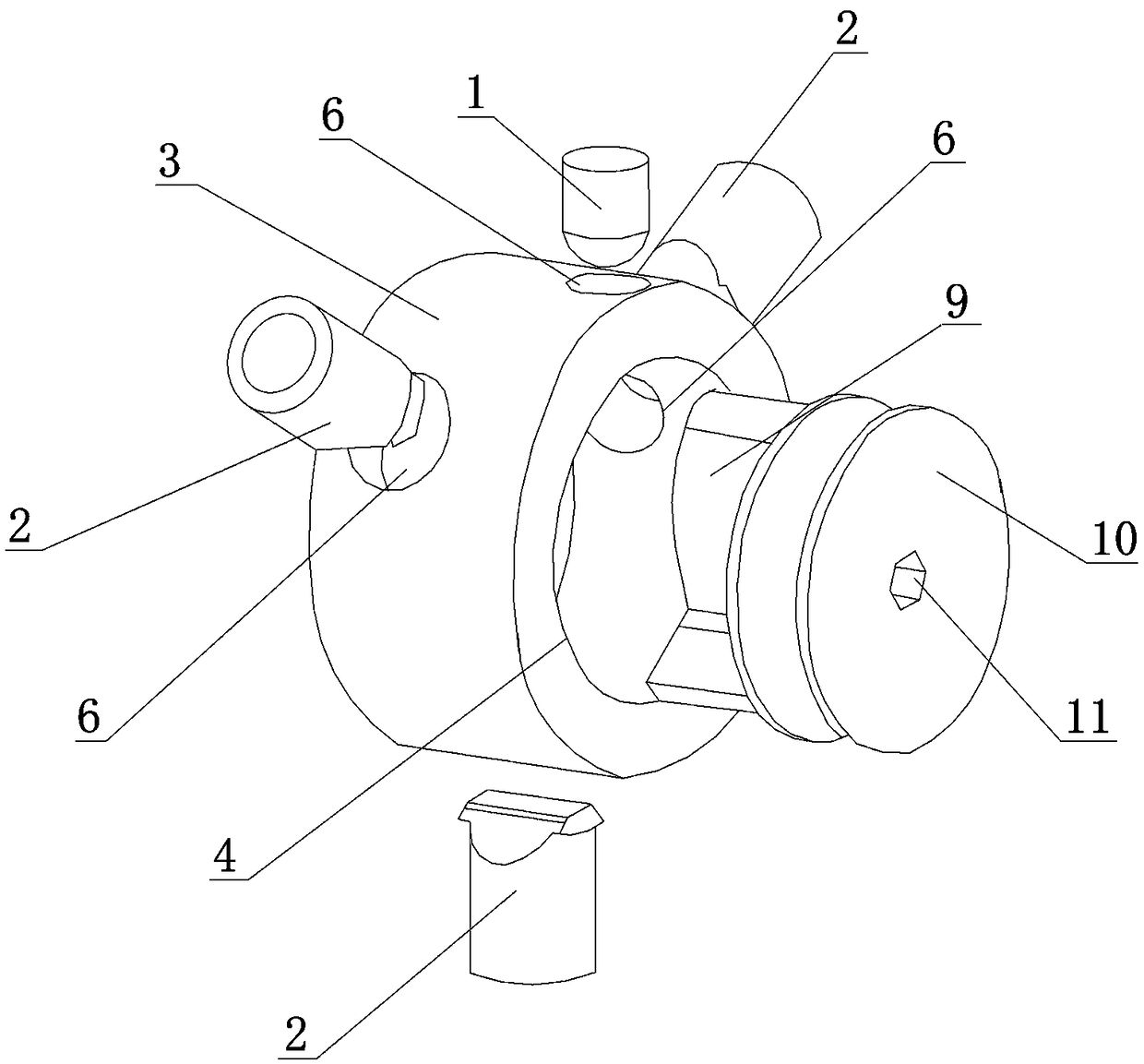

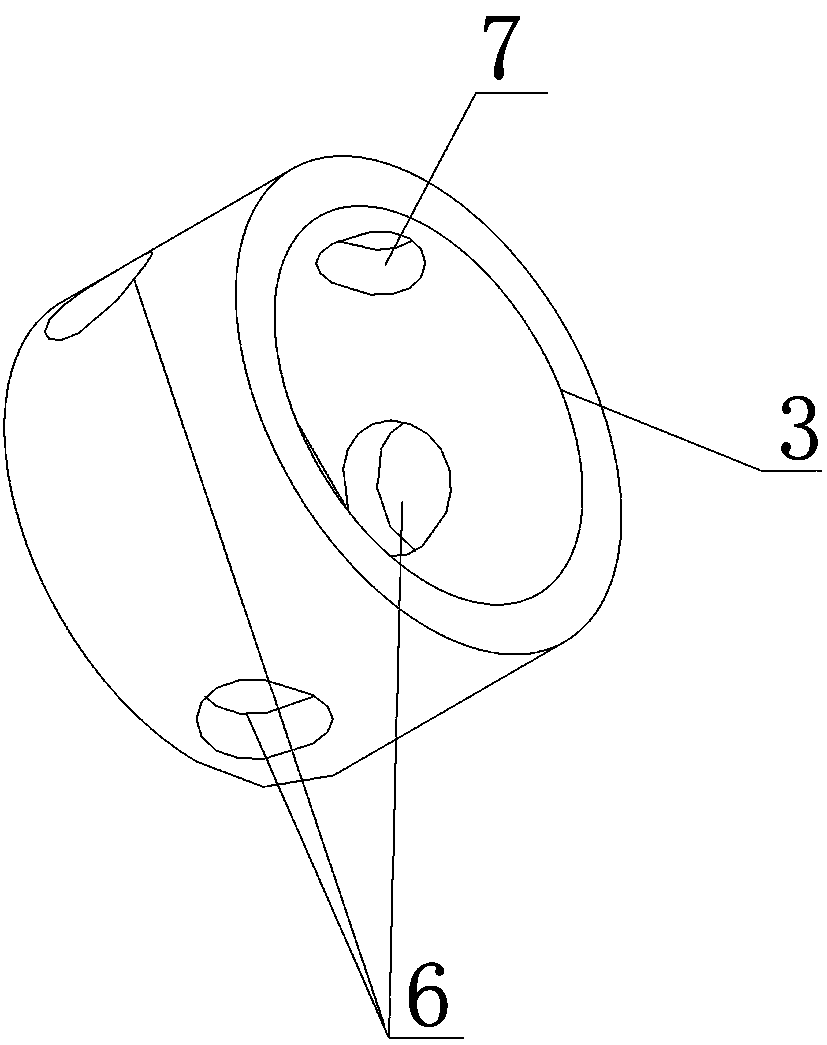

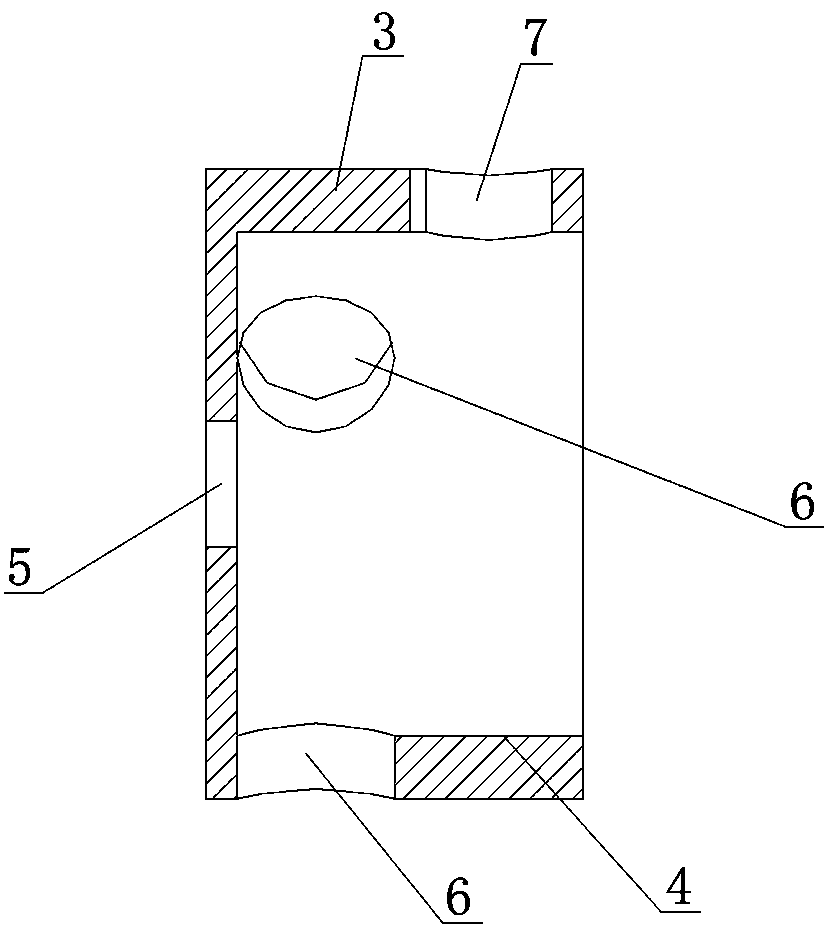

[0021] Such as Figure 1~8 As shown, a soft claw mandrel adjuster includes a support adjuster, a locking screw 1, a support rod 2 and a cylinder 3. One end of the cylinder 3 is closed, and the other end is provided with a cylindrical cavity 4. The closed end of the body 3 is provided with a through hole 5 communicating with the cylindrical chamber 4, and three guide holes 6 communicating with the cylindrical chamber 4 are uniformly provided on the cylinder surface of the cylinder body 3 and along its circumferential direction. A threaded hole 7 communicating with the cylindrical cavity 4 is also provided. The support regulator includes a rotating shaft 8, an impeller 9 and a guide wheel 10. The impeller 9 consists of three equilateral triangles and is fixed on one end surface of the guide wheel 10. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com