A Bevel Cutting Method of Smaller Size Silicon Block

A silicon block and oblique cutting technology, which is applied in the field of silicon block cutting, can solve the problems of increasing the cost of silicon materials, and achieve the effects of reducing scrap rate, improving work efficiency, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A bevel cut method for undersized silicon blocks,

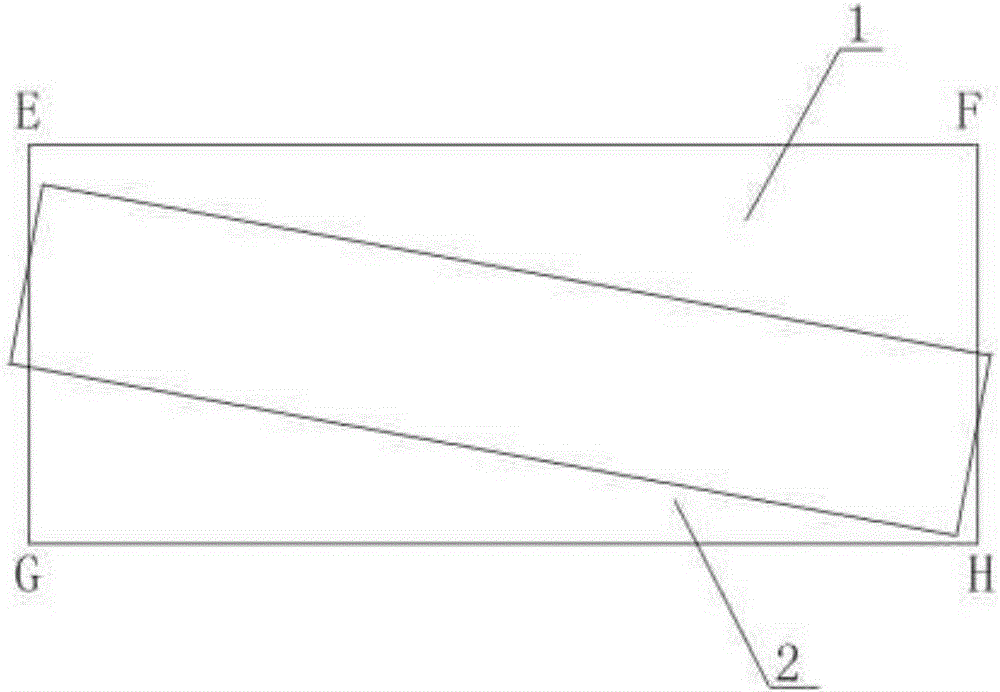

[0031] Such as figure 1 , figure 2 shown, including the following steps:

[0032] Step 1: Select the silicon block to be beveled, measure and record the side length of the smaller side of the silicon block;

[0033] Step 2: Calculate the relative position of bonding the crystal support 2 and the glass plate 1 according to the side length of the smaller side of the silicon block;

[0034] Step 3: According to the calculated data, draw the crystal support boundary line on the glass plate 1, and bond the crystal support 2 to the glass plate 1 according to the crystal support boundary line;

[0035] Step 4: bonding the silicon block on the glass plate 1;

[0036] Step 5: After the silicon block is fixed, the silicon block can be cut, wherein the cutting line is parallel to the short side of the crystal holder 2 .

[0037] In this embodiment, since the length of the hypotenuse is longer than that of the right-angle si...

Embodiment 2

[0039] In this embodiment, on the basis of Embodiment 1, the calculation process of the relative position of the bonding of the crystal support 2 and the glass plate 1 in step 2 is as follows:

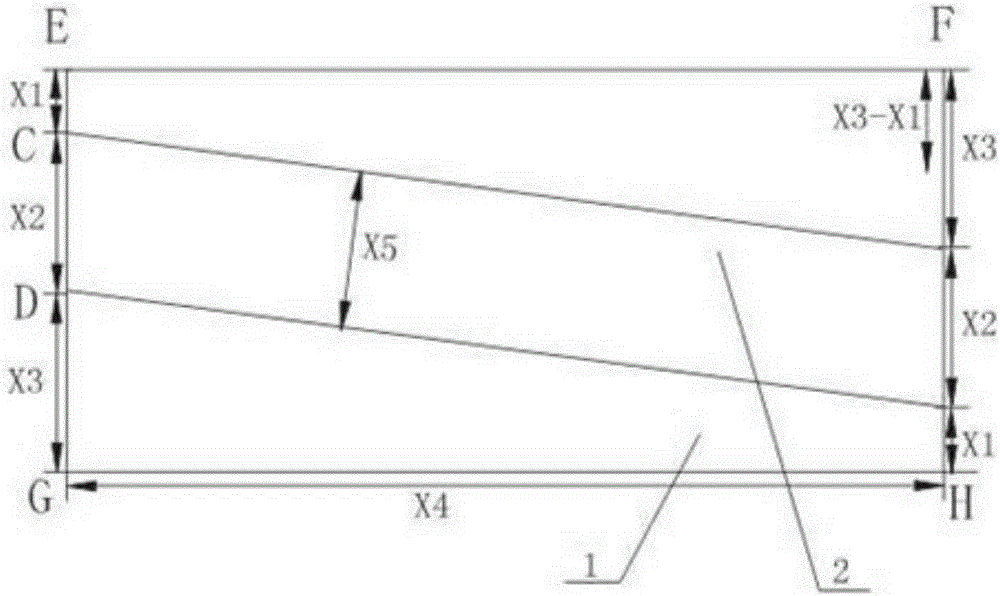

[0040] The four vertices of the glass plate 1 are denoted as E, F, G, H in sequence; the intersection points of the crystal support 2 and one side of the glass plate 1 are respectively C and D.

[0041] according to the formula Calculate the offset length X of the silicon block; wherein Y represents the side length of the smaller side of the silicon block, and B represents the actual length of the silicon block to be achieved;

[0042] according to the formula X 3 X 4 - X 2 X 4 = X Y ;

[0043] x 3 +X 1 =A-X 2 ;

[0044] Cal...

Embodiment 3

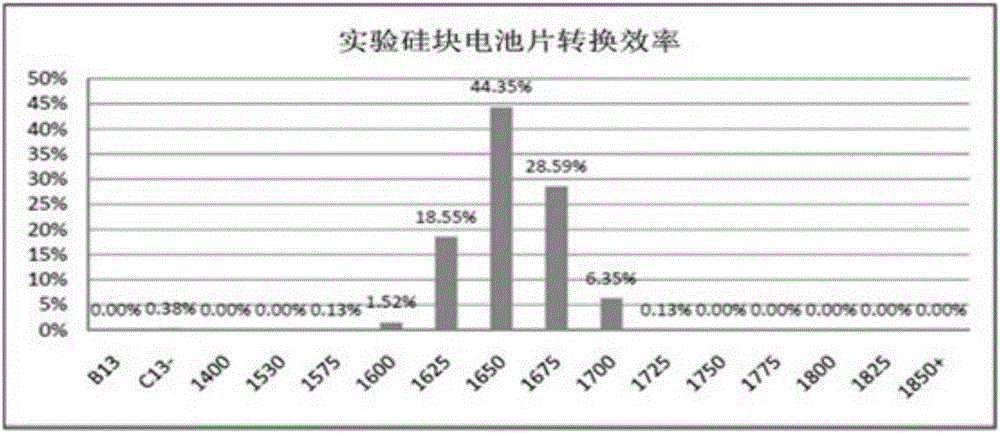

[0073] In this embodiment, on the basis of embodiment 2, the side length of the smaller silicon block Y>(2X 5 .B+X.X 4 ) / A.

[0074] When the side length of the small silicon block Y5 .B+X.X 4 ) / A, the size of the silicon block is too small, the relative position deviation between the glass plate 1 and the crystal support 2 is too large, and the actual operation is difficult. In this case, it is not recommended to use bevel cutting. Therefore, by the side length of the smaller side of the silicon block and (2X 5 .B+X.X 4 ) / A, the recyclable scrap silicon blocks can be quickly screened out, which improves work efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com