Rapid changeover method for laser carving of pattern on surface of power supply and rapid changeover jig

A surface pattern and power supply technology, applied in the field of quick-change jigs, can solve the problems of long debugging time, prone to laser engraving ghosting and misalignment, etc., so as to save the trouble of disassembly and prevent radium engraving ghosting and misalignment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

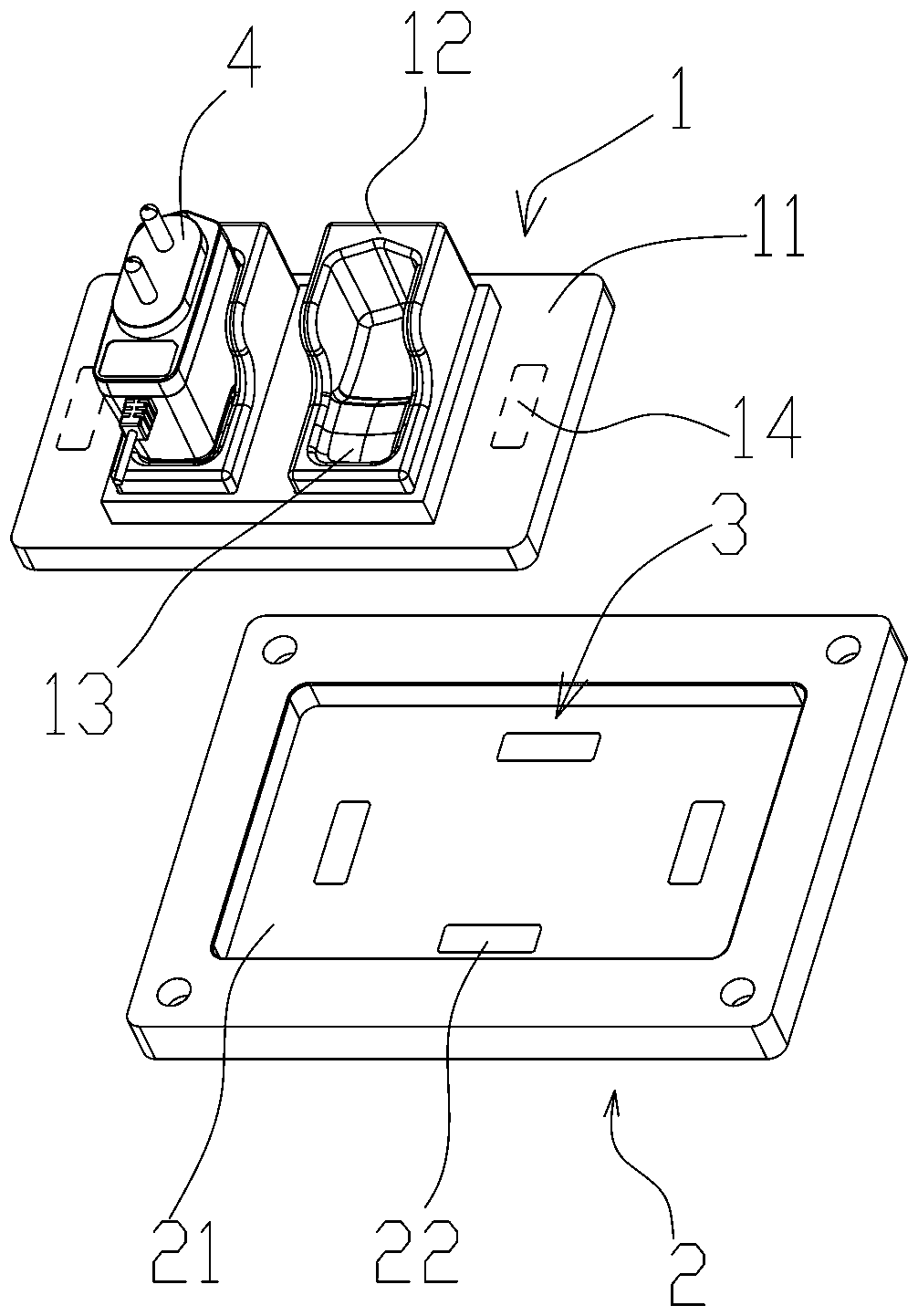

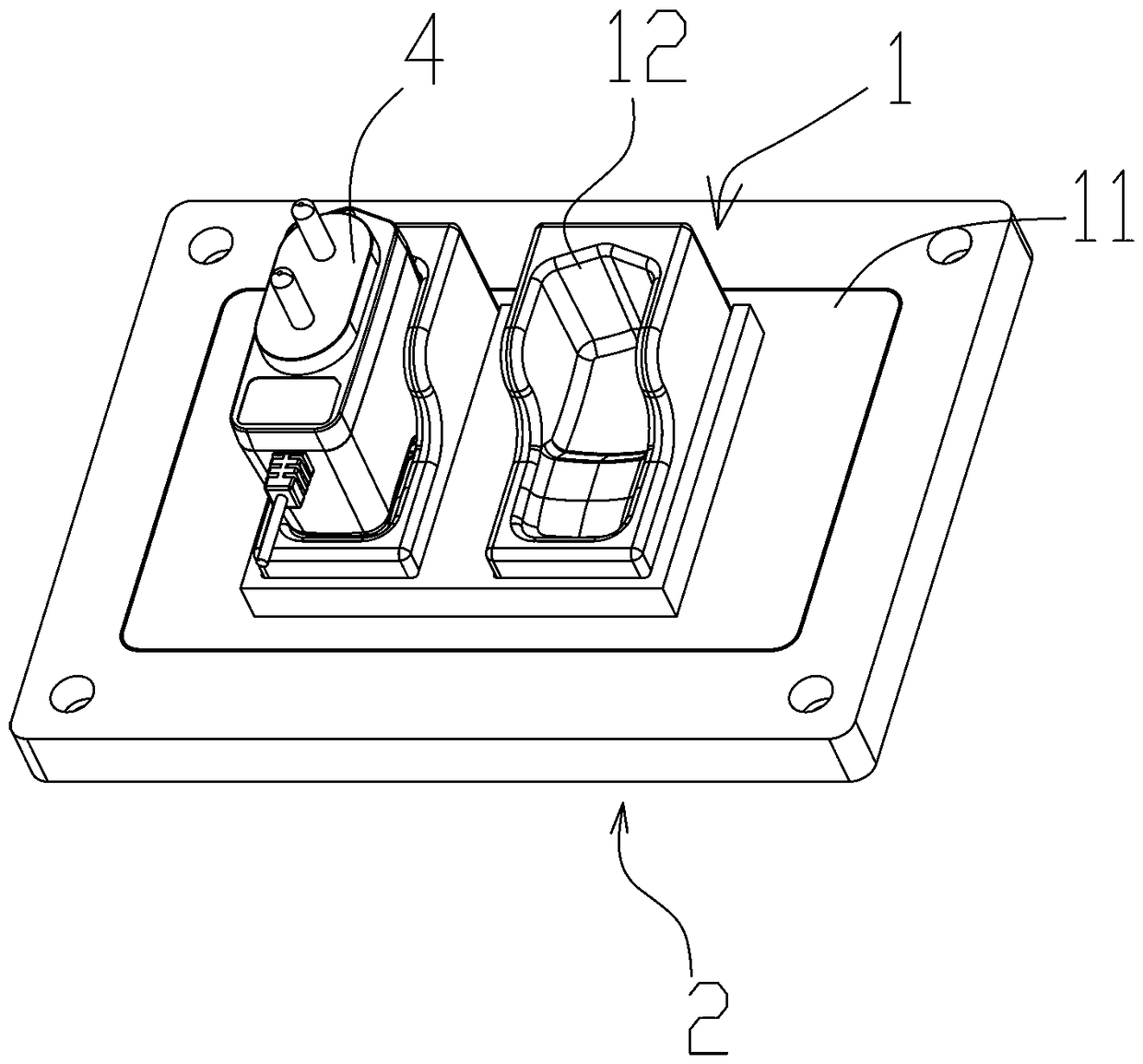

[0023] The content of the present invention will be further described below in conjunction with the accompanying drawings.

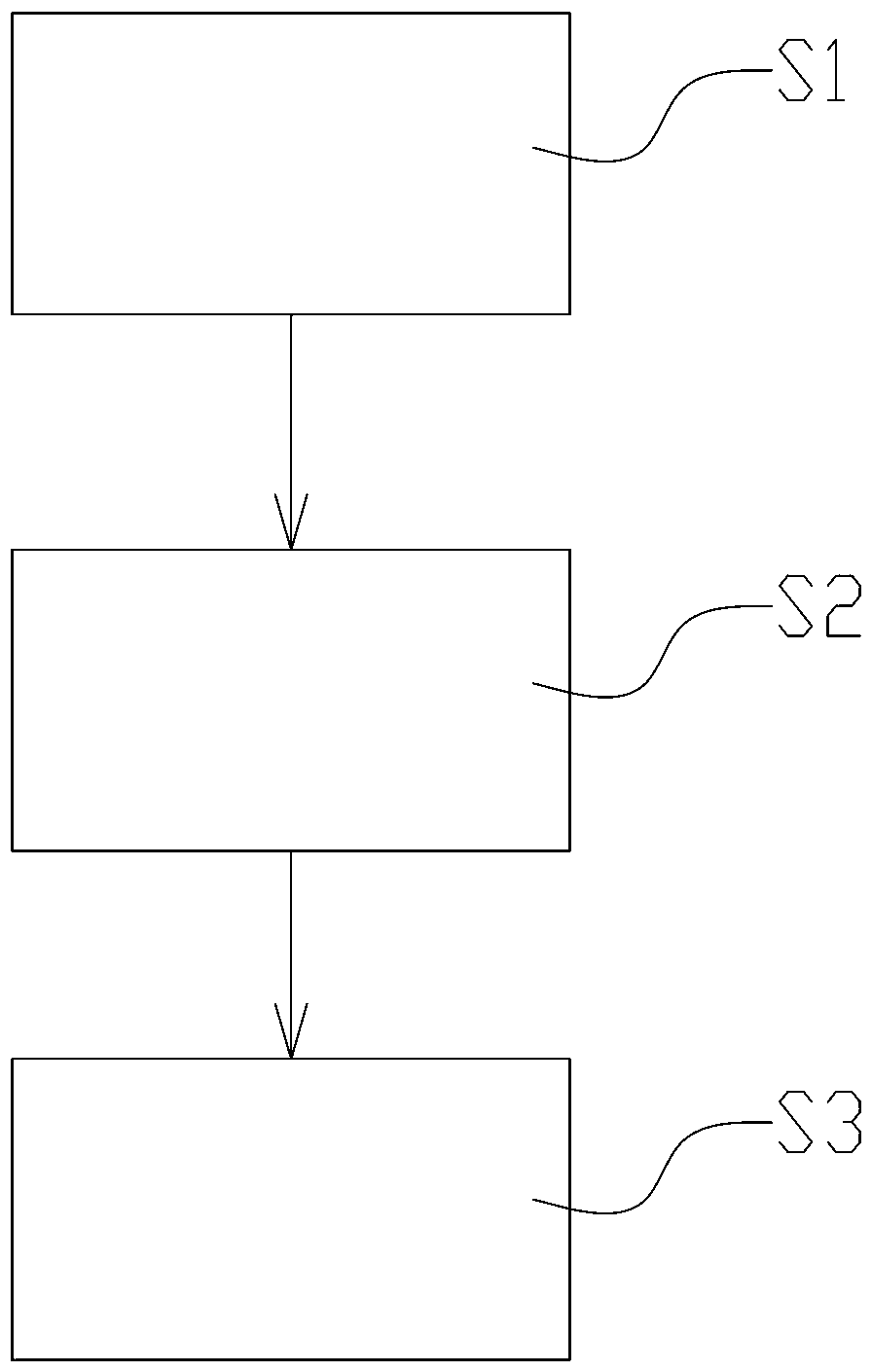

[0024] See figure 1 , figure 1 What is disclosed is a method for rapid type change during laser engraving of power surface patterns, including:

[0025] S1. Superimpose the predetermined type of power supply fixture through the positioning plate of the power supply fixture and the fixture fixing base plate, and quickly position the two through the positioning part between the positioning plate of the power supply fixture and the fixture fixing base plate;

[0026] S2. Put the power supply matching the model of the power supply fixture into the groove of the power supply fixture, and absorb the permanent magnet of the transformer in the power supply through the pre-set magnetic parts in the predetermined position in the groove, and adsorb the power supply to the predetermined position. to automatically calibrate the power position;

[0027] The predete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com