Repair method of chip cooler

A cooler and chip technology, which is applied in the repair field of chip coolers, can solve problems such as water leakage, waste of resources, material changes, etc., and achieve the effect of extending the repair period, prolonging the service life and reducing the repair frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

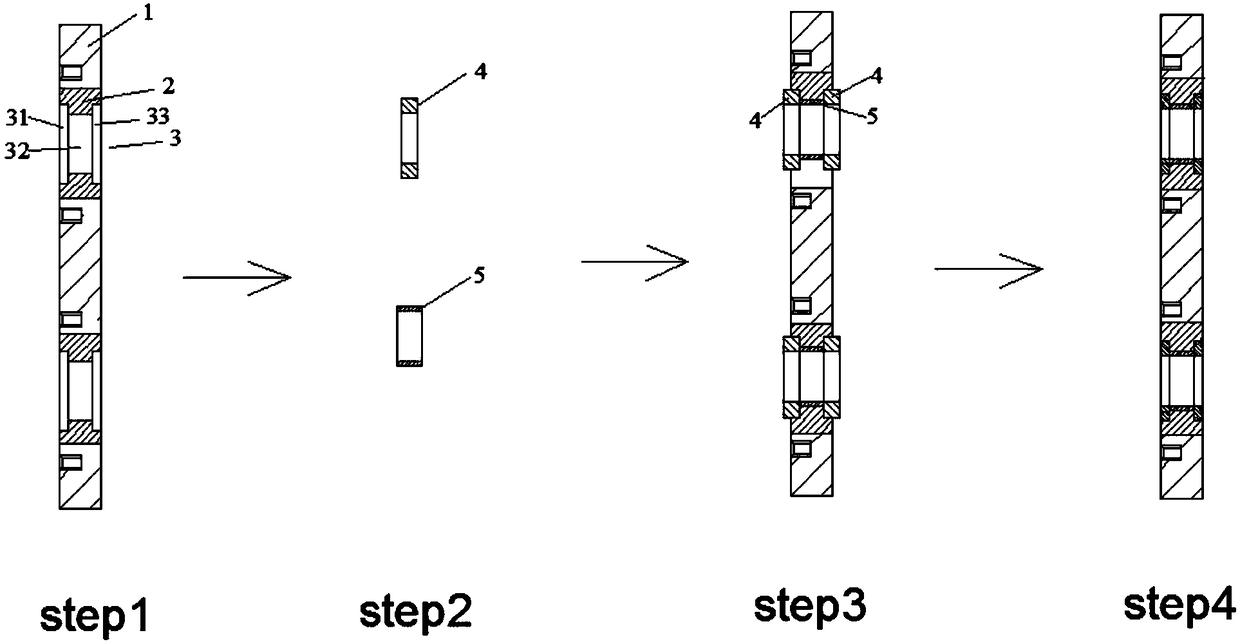

[0033] The repair method of the fin cooler of the present embodiment may further comprise the steps:

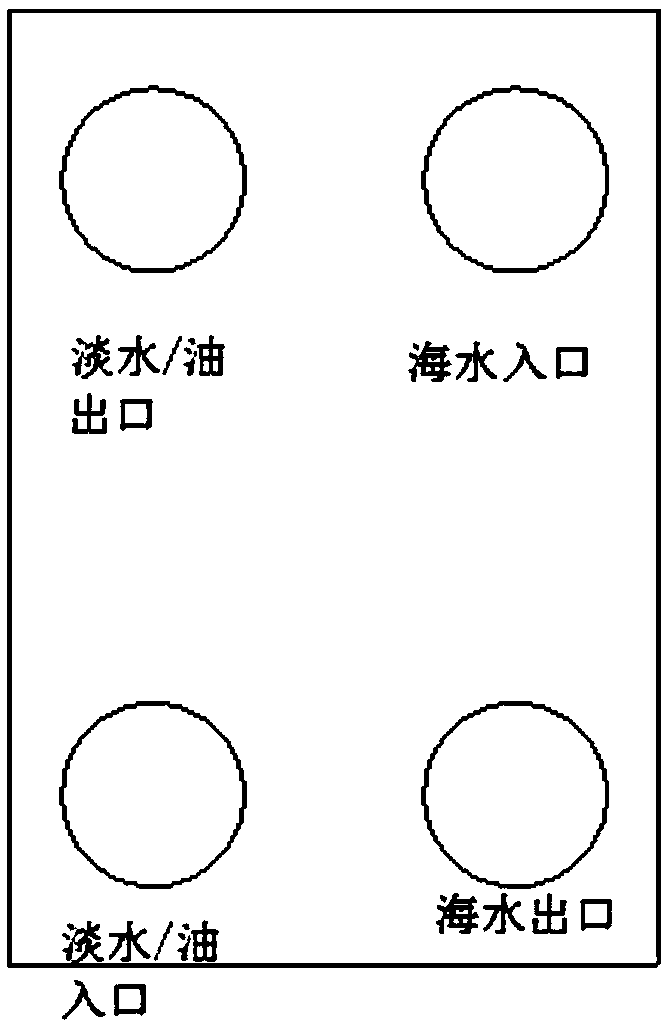

[0034] (1) Machining the water outlet or water inlet of the compression plate 1, increasing the diameter of the inner hole to remove the corrosion part, forming an inner hole channel 3, the left and right sides of the inner hole channel 3 are symmetrical steps shape, including the first stepped passage 31, the straight passage 32 and the second stepped passage 33 which are connected with each other in turn, and the first stepped passage 31, the straight passage 32 and the second stepped passage 33 are all cylindrical, and the first stepped passage 31 and the inner diameter of the second stepped passage 33 is greater than the inner diameter of the straight passage 32, and the lengths of the first stepped passage 31 and the second stepped passage 33 are 5-6 mm;

[0035] (2) Use 316L stainless steel plate to prefabricate the sleeve 5 and the meson 4 respectively, the sleeve 5 is...

Embodiment 2

[0042] The repair method of the fin cooler of the present embodiment may further comprise the steps:

[0043] (1) Machining the water outlet or water inlet of the compression plate 1, the diameter of the inner hole is increased to form an inner hole channel 3, and the left and right sides of the inner hole channel 3 are stepped, including successively mutual Connected first stepped passage 31, straight passage 32 and second stepped passage 33, the first stepped passage 31, straight passage 32 and second stepped passage 33 are cylindrical, the first stepped passage 31 and the second stepped passage The inner diameter of 33 is greater than the inner diameter of the straight channel 32;

[0044] (2) prefabricated sleeve 5 and meson 4 respectively with stainless steel plate, sleeve 5 is used to be installed in straight tube passage 32, and meson 4 is used to be installed in first stepped passage 31 or second stepped passage 32, and meson 4 is an annular barrel;

[0045](3) Put t...

Embodiment 3

[0048] The method for repairing the sheet cooler of this embodiment, wherein step (1) also includes removing the flange on the pressing plate before machining the water outlet or water inlet of the pressing plate, and prefabricating with a stainless steel plate A new flange of the same size as the old flange is installed and fixed on the water outlet or water inlet of the compression plate, and the rest are the same as in Embodiment 1.

[0049] This embodiment is applicable to the situation where the flange on the pressure plate is severely corroded and damaged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com