Screw turning device convenient for clamping and adjusting

A clamping device and screw-tightening technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor intensity, low production efficiency, and poor use effect, and achieve the elimination of safety hazards and simple structure , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

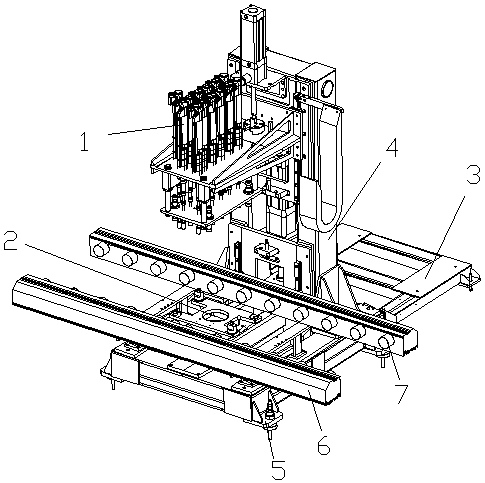

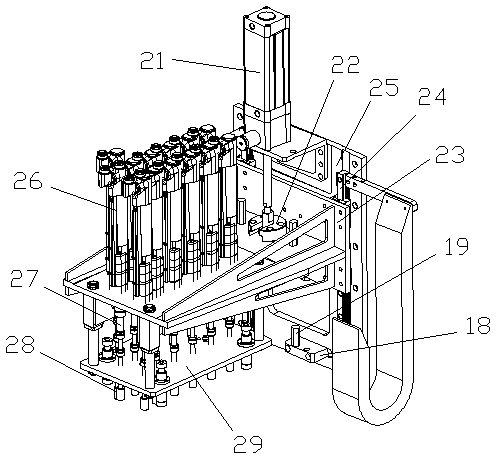

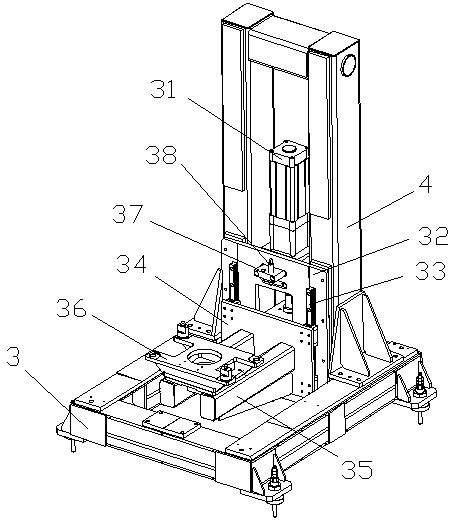

[0034] like Figure 1-Figure 4 As shown, the structure of the present invention is: a screw-tightening device convenient for clamping and adjustment, which includes a base 3 and a fixed block 5, a bracket 4 is arranged on the base 3, and a bracket 4 is arranged below the bracket 4. There is a clamping device 2 that cooperates with the product, and a screwing device 1 is arranged above, and the screwing device 1 includes a screwing movable device and a screwing movable seat 23 that cooperate with each other, and the screwing movable seat 23 is arranged above There is a screwdriver 26, and a screwdriver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com