Lining sleeve milling groove machining tooling

A technology for milling grooves and bushings, which is applied in metal processing equipment, metal processing mechanical parts, positioning devices, etc., can solve the problems of troublesome positioning, time-consuming, and large errors of cylindrical structures, and achieves low power, efficiency, and efficiency. Improved accuracy and reduced friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

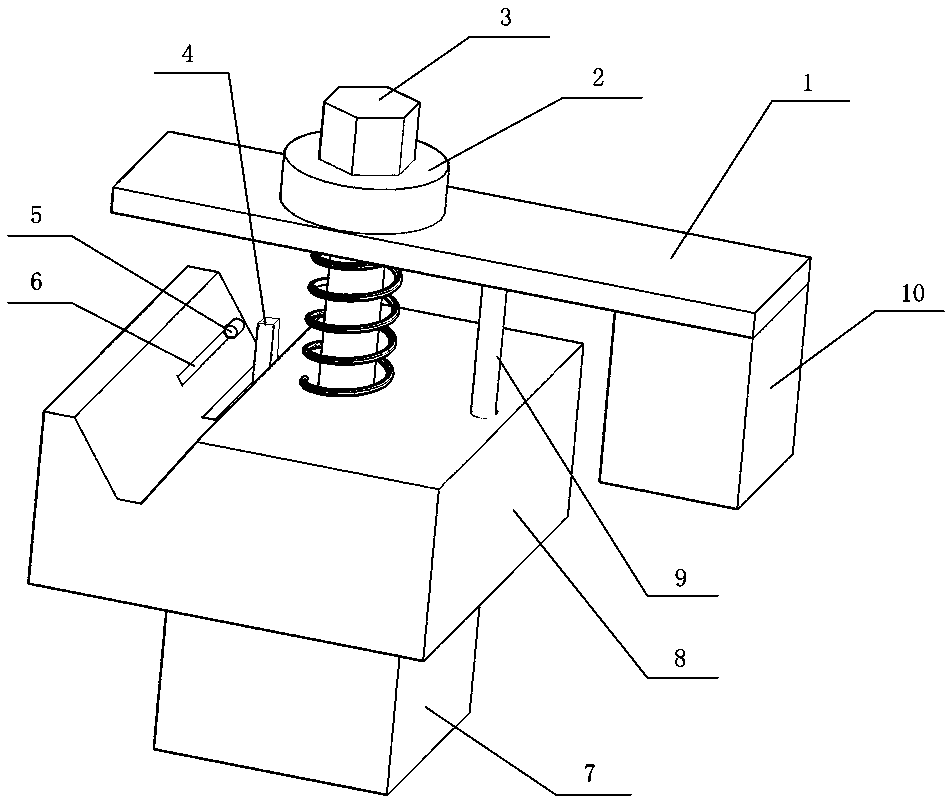

Embodiment 1

[0026] In the bush milling tooling described above, a spring 17 is sleeved on the part of the pressing bolt 3 between the pressing plate 1 and the clamping block 8; The lower part is provided with a rotating shaft chamber 16 adapted to the rotating shaft 15 , and the rotating shaft 15 is hinged to the side walls at both ends of the rotating shaft chamber 16 .

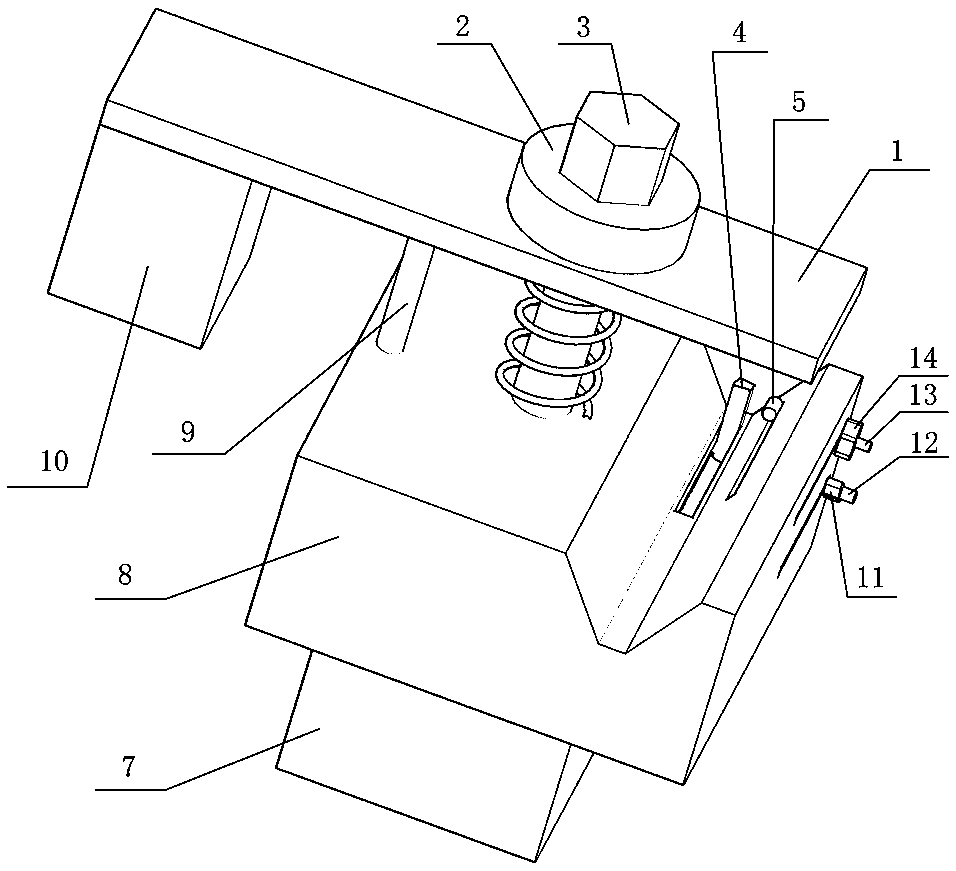

Embodiment 2

[0028] In the bush milling tooling described above, a counterweight 10 is provided at the rear of the pressure plate 1; a rotating shaft 15 is provided at the upper end of the support column 9, and a rotating shaft cavity 16 adapted to the rotating shaft 15 is provided at the lower part of the pressing plate 1. The rotating shaft 15 is connected to the rotating shaft chamber 16 in a detachable and rotatable manner.

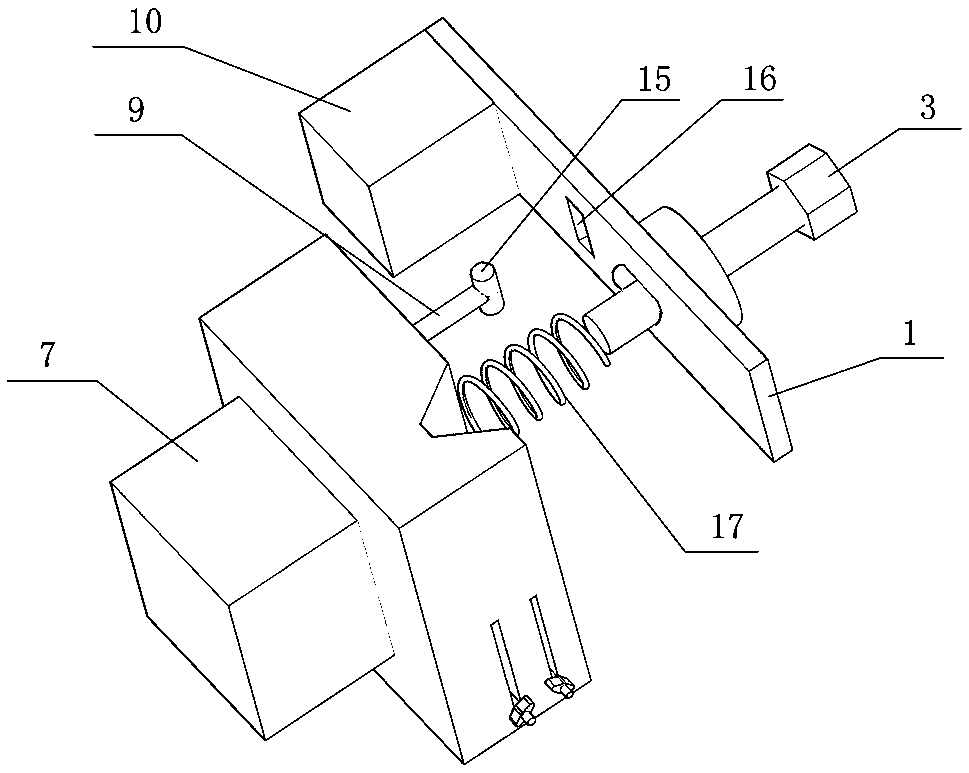

Embodiment 3

[0030] In the bush milling tooling described above, a counterweight 10 is provided at the rear of the pressure plate 1, and a spring 17 is sleeved on the part of the compression bolt 3 between the pressure plate 1 and the clamping block 8; the upper end of the support column 9 A rotating shaft 15 is provided, and a rotating shaft chamber 16 adapted to the rotating shaft 15 is provided at the lower part of the pressure plate 1 , and the rotating shaft 15 is connected to the rotating shaft chamber 16 in a rotatable manner.

[0031] The working principle is: because the milling cutter is vertically above, the uppermost part of the first stop disc 21 is the starting point, and the vertical hole at the bottom of the first stop disc 21 opposite to the starting point is the end hole, and the central angle between the connecting hole and the starting point is For the angle suitable for positioning, that is, the central angle between the connection hole and the starting point is equal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com