Duct-type ship propeller

A propeller, ducted technology, applied in the direction of rotary propeller, hull design, rotating propeller, etc., can solve the problems of unstable sailing and increase power loss, achieve smooth sailing, reduce power loss and improve safety and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

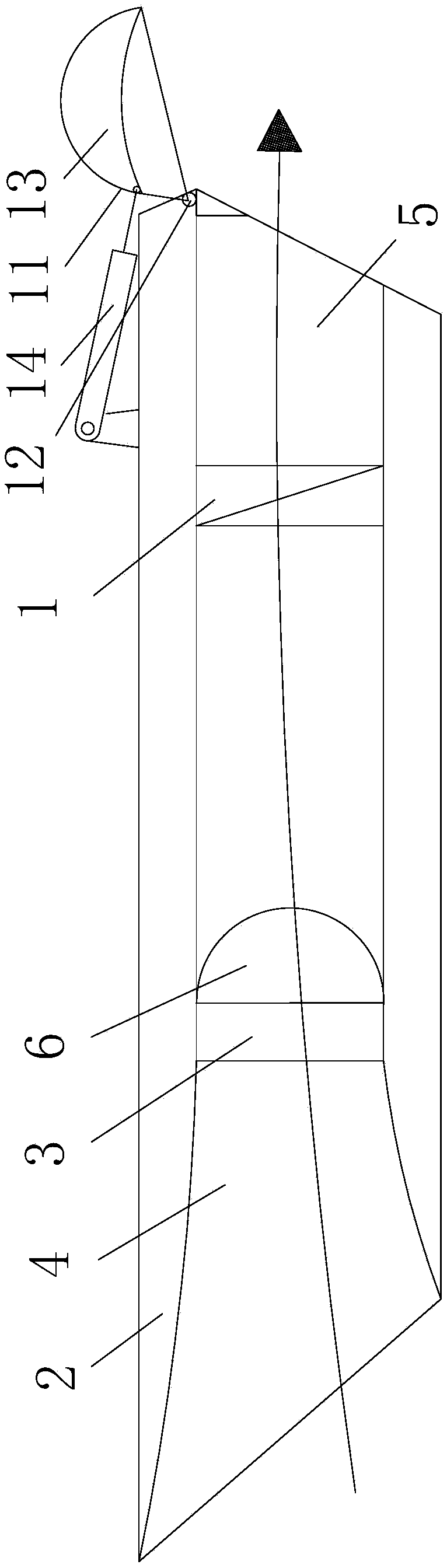

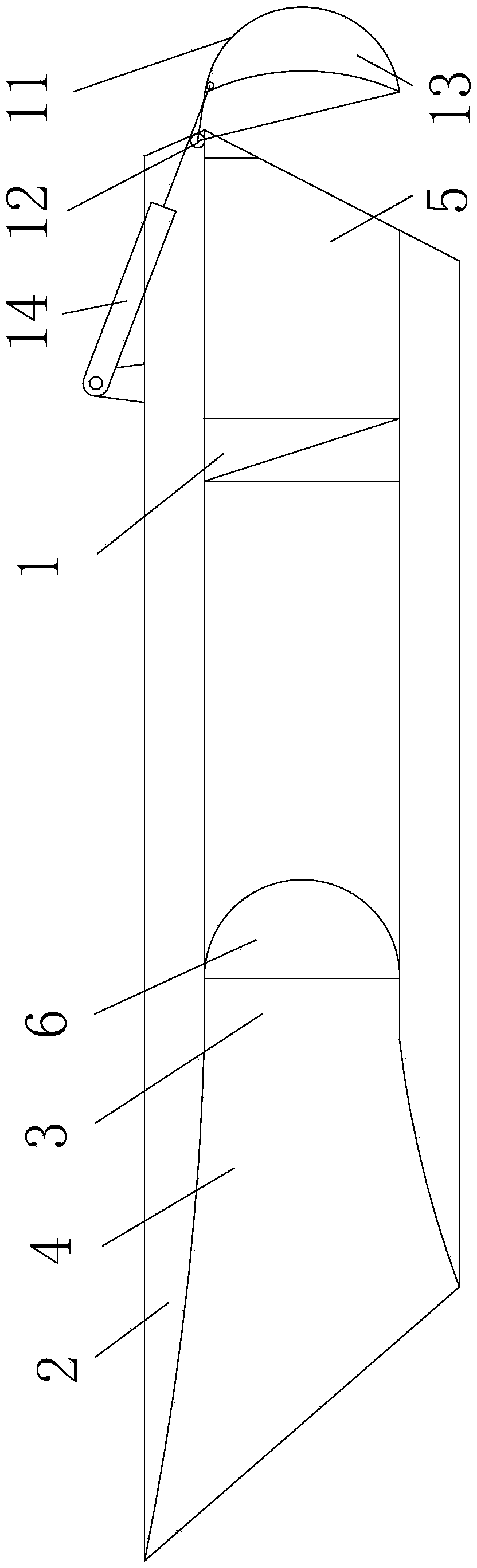

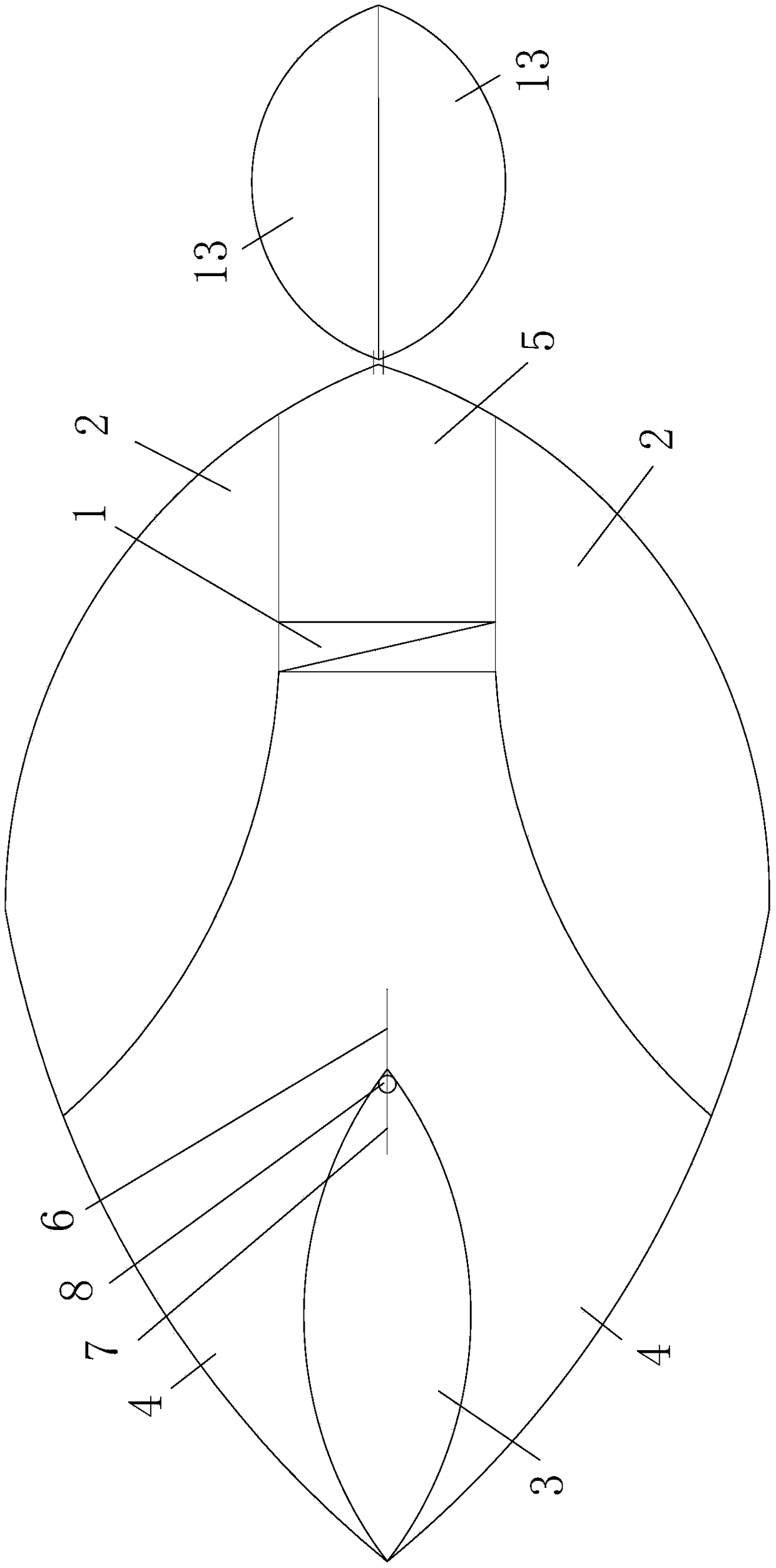

[0026] Example 1, as attached figure 1 Attached Figure 7 Shown: a ducted ship propeller, including: a propeller 1, a shell 2 arranged in the lower part of the hull (not shown in the figure), a partition 3 arranged in the shell 2, symmetrically arranged in the middle Two inlets 4 on both sides of the partition 3 and through the front end of the housing 2, a built-in rudder arranged on the intermediate partition 3, and an outlet 5 at the rear end of the housing 2 and the front end communicates with the rear end of the inlet 4 ; The propeller 1 is located in the water outlet 5; the lower side of the inlet end of the water inlet 4 is lower than the no-load waterline of the hull; the horizontal median plane of the water inlet 4 is lower than the full-load waterline of the hull.

[0027] The built-in rudder includes: a middle rudder plate 6, a middle lever 7 connected to the upper end of the middle rudder plate 6 at the rear end, and a front rudder shaft 8 whose upper end is screwed to...

Embodiment 2

[0033] Example 2, as attached Figure 8 Shown, and see attached figure 1 Attached Figure 4 , Attached Figure 7 : A ducted ship propeller, comprising: a propeller 1, a shell 2 arranged in the lower part of the hull, two laterally symmetrical water channels 15 arranged in the shell 2 and passing through the front end of the shell 2; The front end and the rear end correspond to the front and rear ends of the shell 2 through one by one; there are two propellers 1; the two propellers 1 are arranged in the two water channels 15 one by one; the lower side of the inlet end of the water channel 15 is lower than the hollow of the hull Load waterline; the horizontal median of channel 15 is lower than the full load waterline of the hull.

[0034] The ducted ship propulsion also includes: an emergency stop and reverse rudder 11 formed at the rear end of the shell 2 and composed of two symmetrically arranged sub-rudders; the sub-rudder includes: one end and the upper end of the shell 2 are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com