Batch pipe arranging and sequencing device

A technology for sorting and sorting pipes, which is applied in transportation and packaging, rotary printing machines, printing, etc., can solve the problems of poor production efficiency of sorting and sorting batches of pipes, increase the labor intensity of personnel, and affect product quality, so as to achieve sorting and stable transmission , Accuracy of coding and sorting, improvement of product quality, and reduction of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

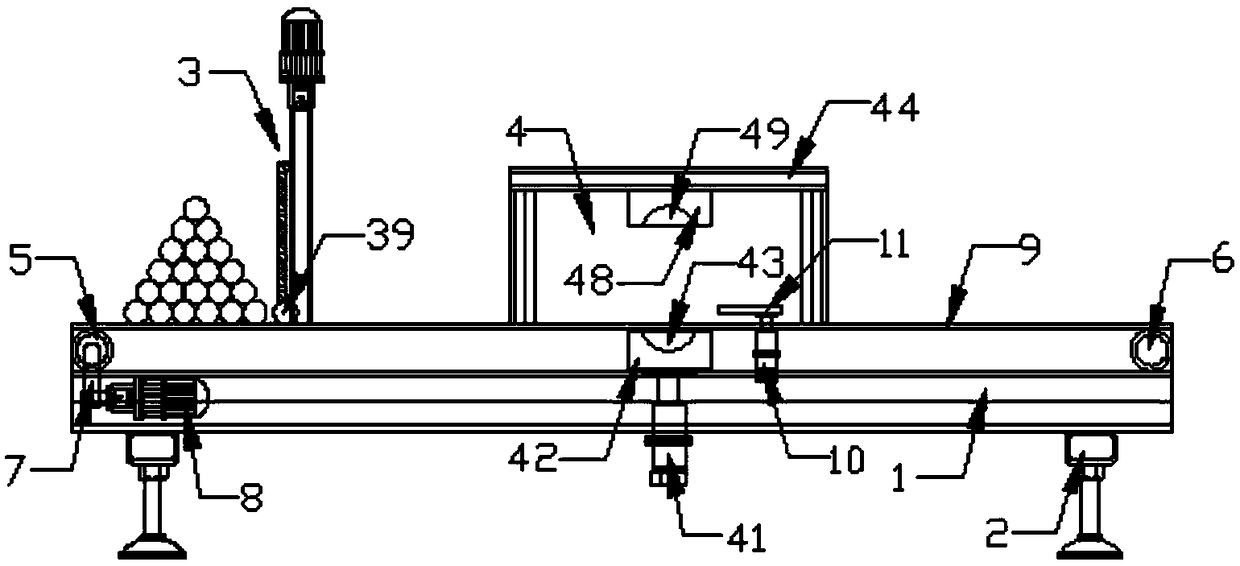

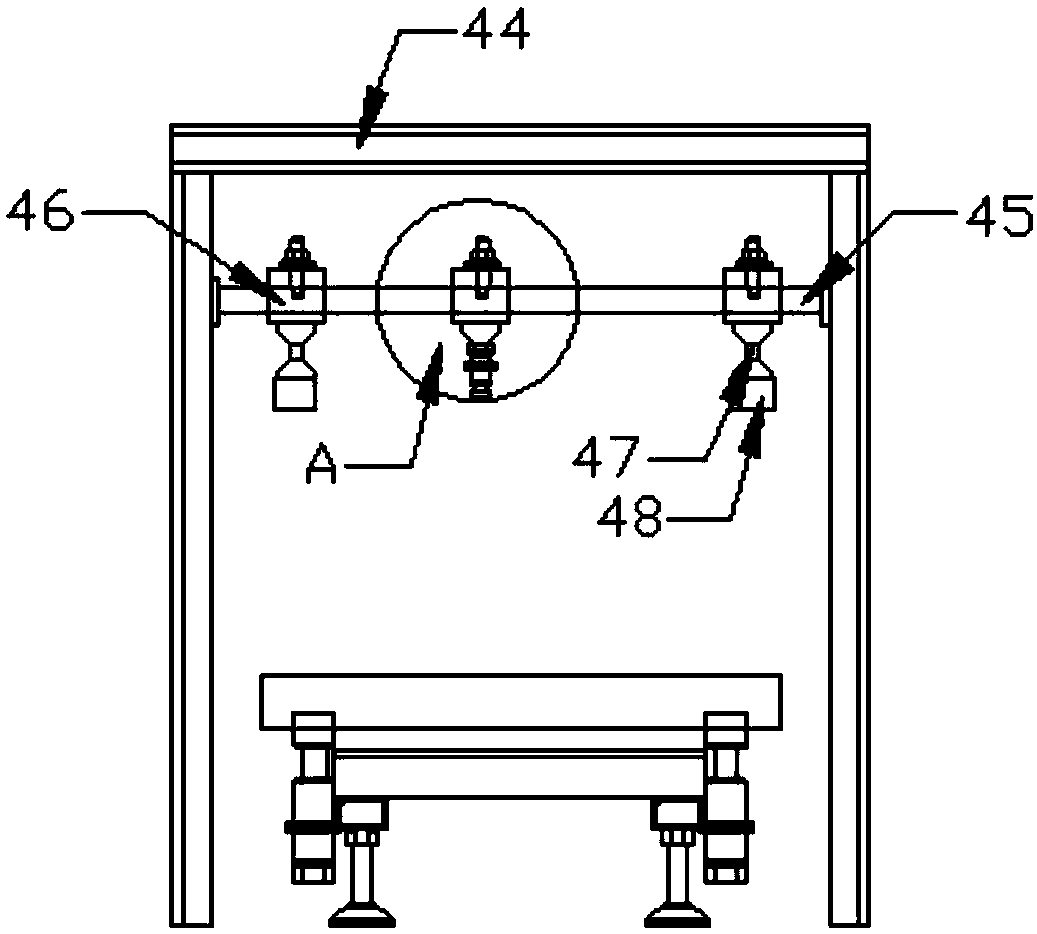

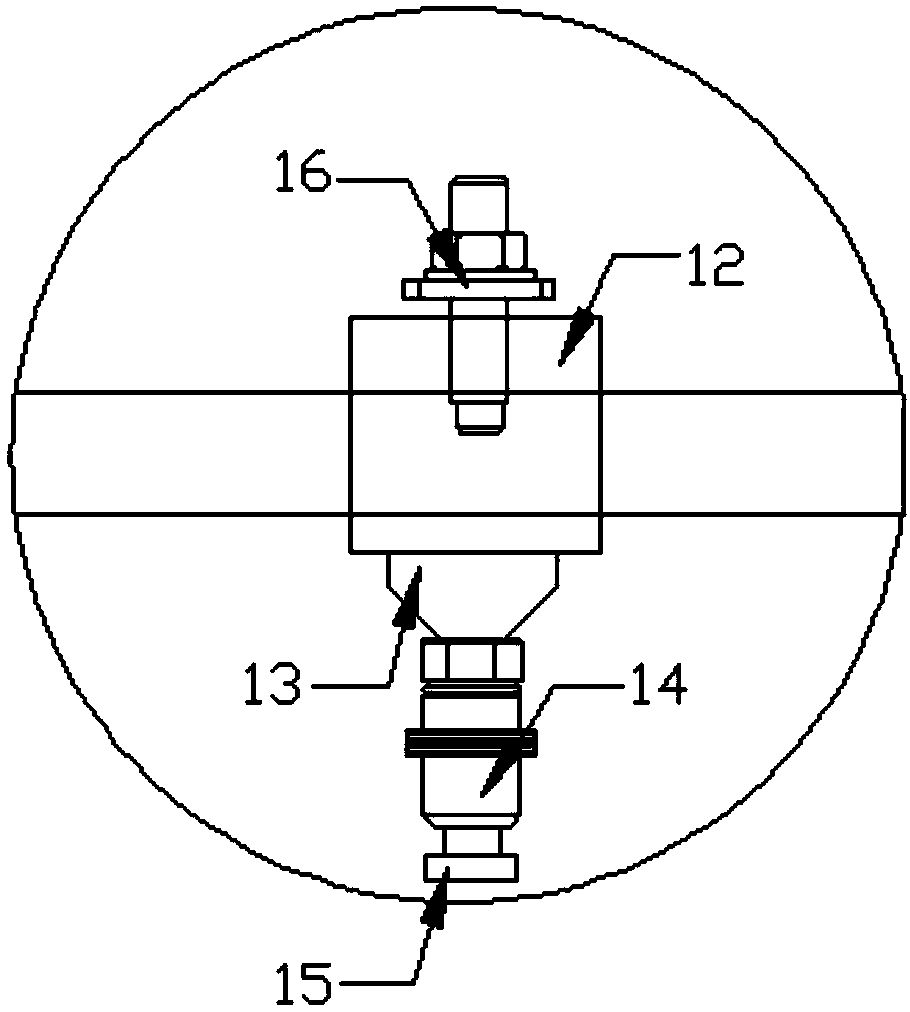

[0022] Such as Figure 1-5 As shown, this specific embodiment adopts the following technical solutions: a batch sorting and sorting device for pipes, including a sorting and sorting workbench 1, a pipe sorting mechanism 3, a pipe positioning and sorting mechanism 4, a conveyor belt 9, a limit baffle 11 and a coding machine 15. A plurality of shock-absorbing support bases 2 are fixedly installed on the bottom of the sorting and sorting workbench 1, rubber shock-absorbing pads are fixedly installed on the bottom of the shock-absorbing support base 2, and one end of the top of the sorting and sorting workbench 1 is installed There is a pipe material sorting mechanism 3, and the other end of the top of the sorting and sorting workbench 1 is equipped with a pipe material positioning and sorting mechanism 4, and the opposite ends of the top of the sorting and sorting workbench 1 are equipped with driving rollers 5 and driven rollers 6. The roller shaft at one end of the driving roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com