Spring Indexing Mechanism

An indexing mechanism and indexing technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of particularly serious production impact, backward operation methods, high labor intensity, etc., to improve the level of production automation, accurate High reliability and reliability, and the effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

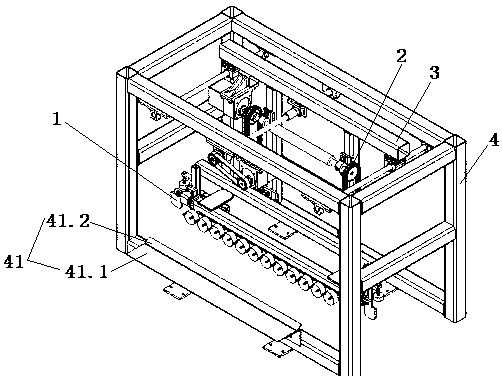

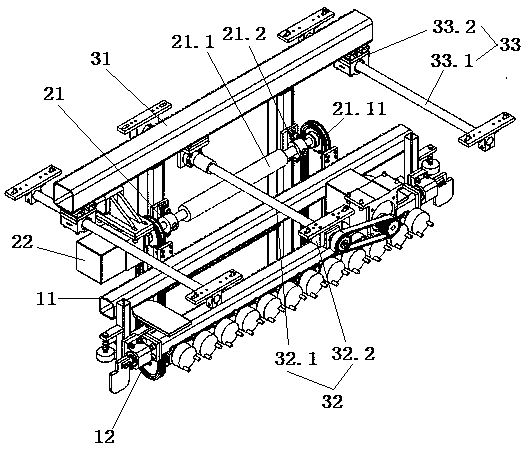

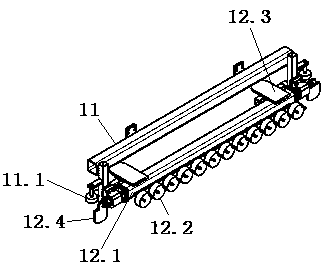

[0020] Combine below Figure 1 to Figure 3 Embodiments of the present invention are described in detail.

[0021] The spring indexing mechanism includes a frame 4, which is characterized in that the frame 4 is equipped with an indexing electromagnet assembly 1 that can drive the spring from horizontal to vertical, and can drive the indexing electromagnet assembly 1 to lift vertically. The lifting assembly 2, the horizontal moving assembly 3 that can drive the indexing electromagnet assembly 1 to move in the horizontal direction, the indexing electromagnet assembly 1 is installed on the lifting assembly 2, the lifting assembly 2 is installed on the horizontal moving assembly 3, multiple horizontal The arranged springs are adsorbed side by side on the indexing electromagnet assembly 1, and the indexing electromagnet assembly 1, lifting assembly 2 and horizontal moving assembly 3 are uniformly controlled by the control system.

[0022] As shown in the figure, the indexing electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com