Construction method for demountable and mountable concrete shear wall with adjustable bearing capacity

A concrete shear wall, construction method technology, applied in the direction of walls, building components, buildings, etc., can solve the problem of not being able to be reused

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

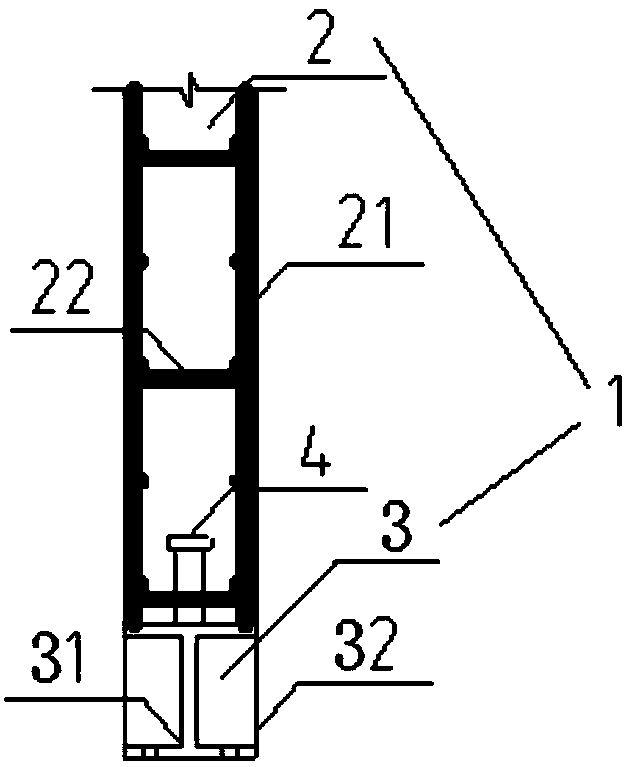

Embodiment 1

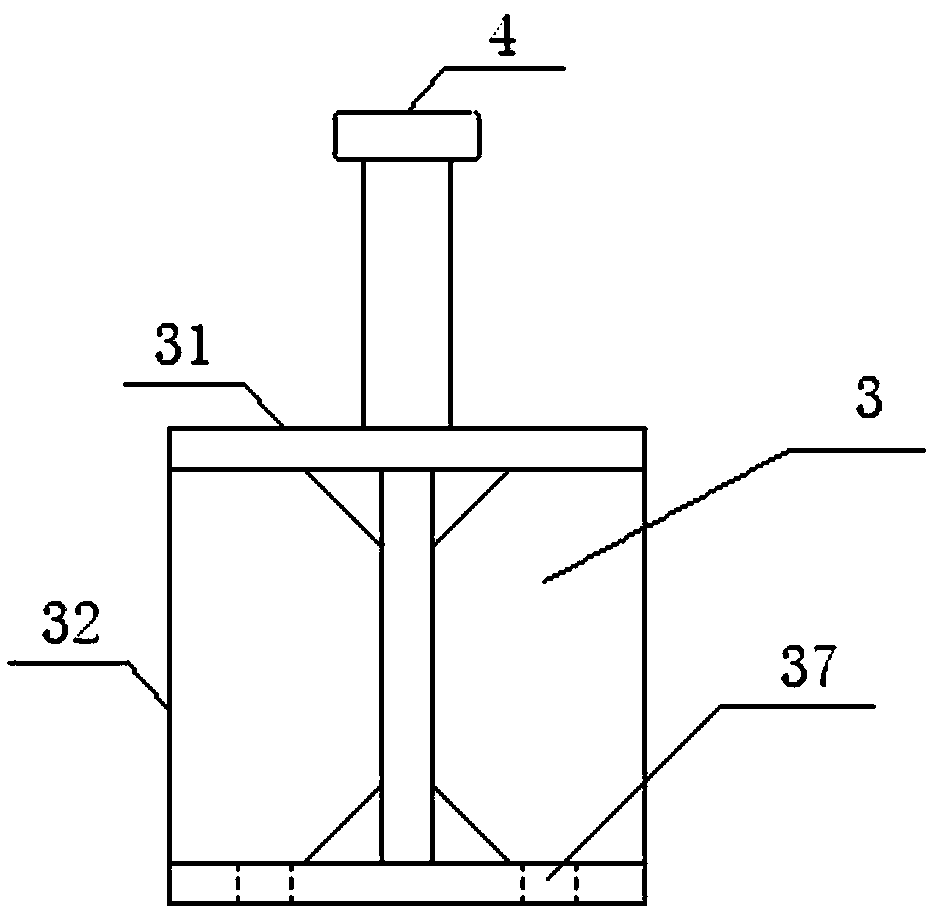

[0128] To prepare a detachable concrete shear wall with adjustable bearing capacity, the concrete wall section is set first. The section size of the concrete wall section needs to bear the same load as that of the integral concrete shear wall. Among the section dimensions of the concrete wall section, the length ( L) is 1000-3000mm, width (W) is 150-300mm. Bind longitudinal steel bars and transverse stirrups in the concrete wall section to make a reinforcement cage, the longitudinal reinforcement and transverse stirrups are evenly distributed in the reinforcement cage, the distance between the adjacent longitudinal reinforcements is 80-200mm, and the adjacent transverse stirrups The spacing between them is 80-200mm.

[0129] Then, set a plurality of studs in the concrete wall section, the diameter φ of the studs is 16-18mm, and the length is 40-80mm. The studs are evenly distributed within the concrete wall section with a spacing of 90-110mm between adjacent studs.

[0130] ...

Embodiment 2

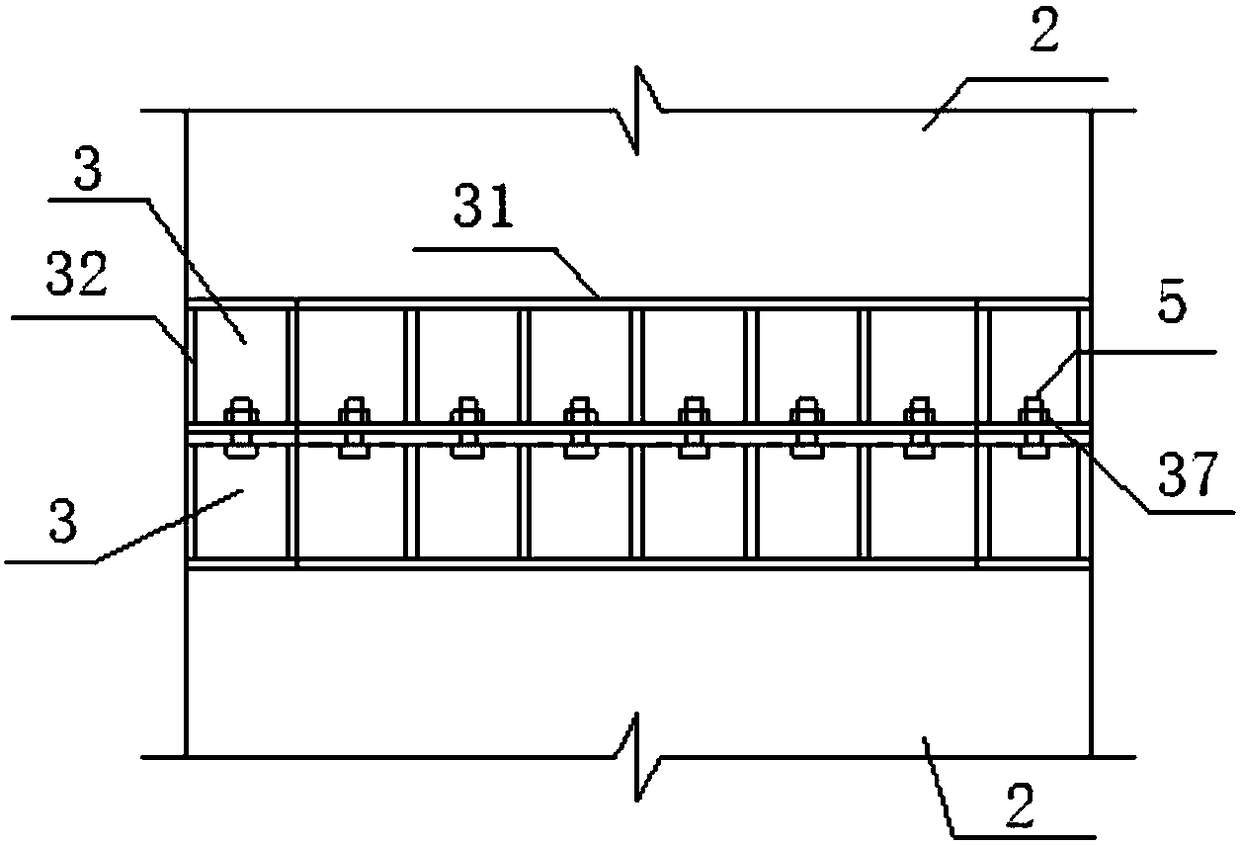

[0137] According to the construction method in Example 1, a detachable concrete shear force example wall was made, using C30 concrete, the height of the wall was 2400mm, the length of the wall was 800mm, and the width was 200mm; the connecting nodes used 8.8 grade M14 bolts, a total of two There are 16 bolts in a row, the spacing along the length direction of the wall is 100mm, and the spacing along the width direction of the wall is 50mm. Relevant performance tests were carried out on this example wall, and relevant performance tests were carried out on the currently conventional monolithic concrete shear walls of the same size. The relevant performance test results of the two are shown in Table 1.

[0138] Table 1 Comparison of performance indicators

[0139] project

[0140] It can be seen from Table 1 that the cross-sectional bending bearing capacity and cross-sectional shearing bearing capacity of the detachable concrete shear wall of the present invention are s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com