Electronic water pump and new energy automobile with electronic water pump

A technology of electronic water pump and pin insertion, which is applied to parts, pumps, and pump devices of elastic fluid pumping devices, and can solve problems such as easy water leakage, poor heat dissipation of electronic water pumps, and difficult assembly of electrical interfaces, etc., to achieve The effect of firm installation, good waterproof effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

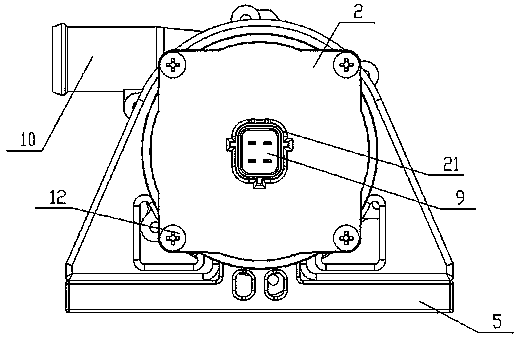

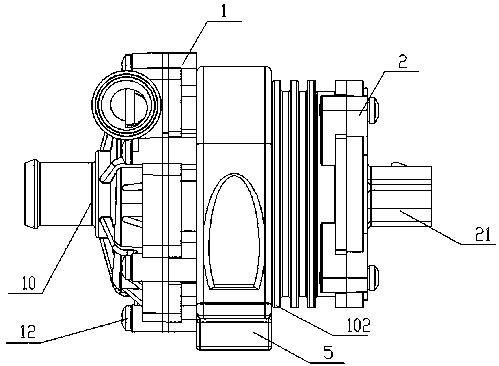

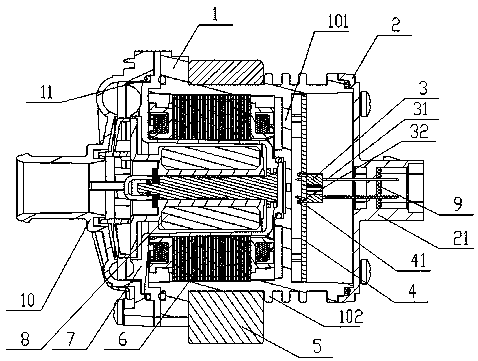

[0030] Such as figure 1 , 2 As shown in . Stator assembly 6, controller 4, screws 12, sealing ring 11, back cover 2, sealing gasket 9 and pin assembly 3, the back cover 2 is injection molded with electrical interface limiting shell 21, the pin assembly 3 Fixed in the corresponding hole of the PCB board 41 of the controller 4, the pin assembly 3 is formed by injection molding of several pins 31 and plastic particles, and one end of the pin assembly 3 is inserted into the electrical interface limiting shell of the rear cover 2 21 and the gasket 9, the other end of the pin assembly 3 is inserted into the corresponding hole of the controller 4, and welded with the controller 4.

[0031] The pin assembly 3 is provided with several barbs 32 , which are engaged with the PCB board 41 of the controller 4 through the barbs 32 to limit the displacement of the pin assembly 3 .

[0032] The injection molding part of the back cover 2 and pin assembly 3 is made of polyphenylene sulfide, a...

Embodiment 2

[0047] Such as figure 1 , 2As shown in . Stator assembly 6, controller 4, screws 12, sealing ring 11, back cover 2, sealing gasket 9 and pin assembly 3, the back cover 2 is injection molded with electrical interface limiting shell 21, the pin assembly 3 Fixed in the corresponding hole of the PCB board 41 of the controller 4, the pin assembly 3 is formed by injection molding of several pins 31 and plastic particles, and one end of the pin assembly 3 is inserted into the electrical interface limiting shell of the rear cover 2 21 and the gasket 9, the other end of the pin assembly 3 is inserted into the corresponding hole of the controller 4, and welded with the controller 4.

[0048] The pin assembly 3 is provided with several barbs 32 , which are engaged with the PCB board 41 of the controller 4 through the barbs 32 to limit the displacement of the pin assembly 3 .

[0049] The injection molding material of the back cover 2 and pin assembly 3 is polyphenylene sulfide, and 33...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com