Universal joint for internal threads and external threads, pipeline, method and closestool

A technology of external threaded joints and universal joints, which is applied in the field of pipe connection devices, can solve the problems of large joint size, affect the appearance, and increase the sealing process, etc., and achieve the effect of small joint size, beautiful connection effect, and reduced sealing nodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

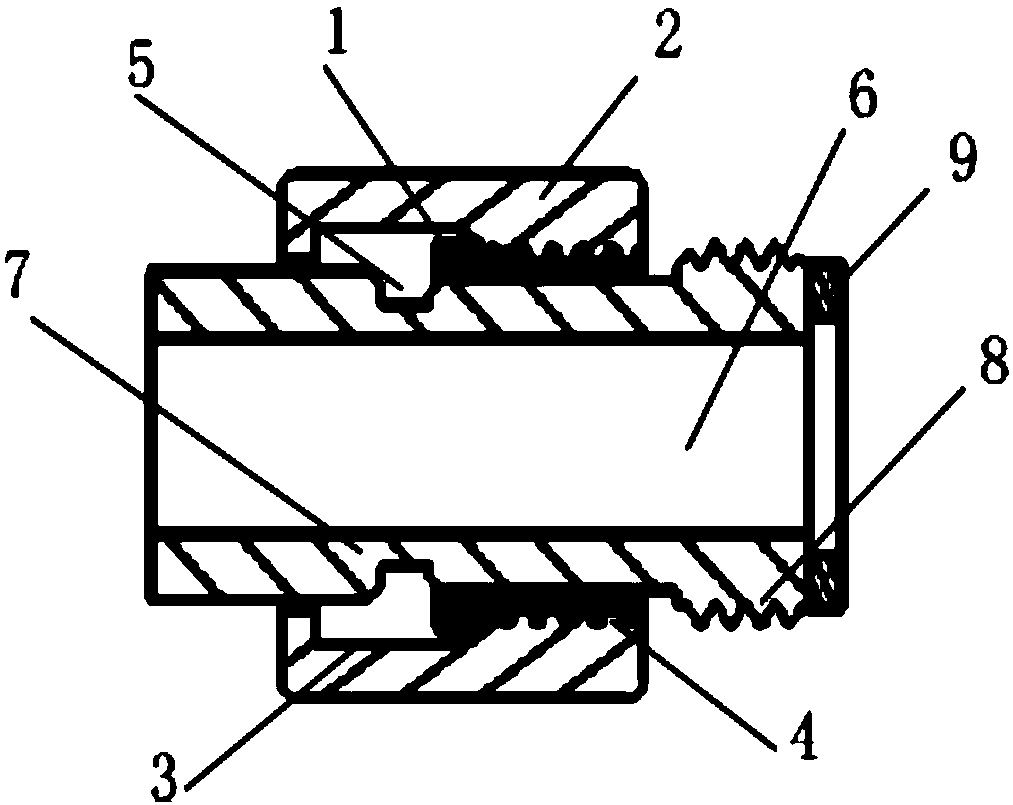

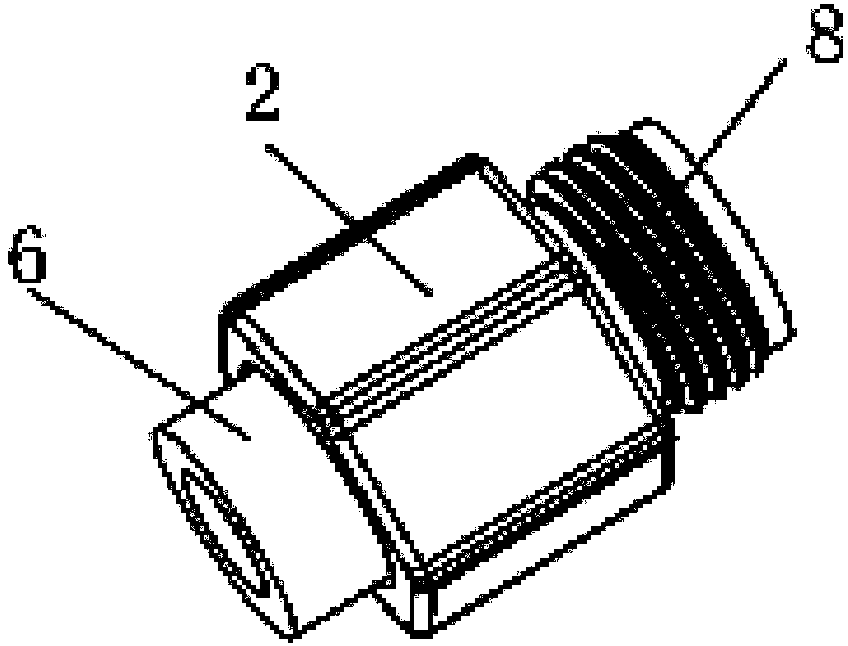

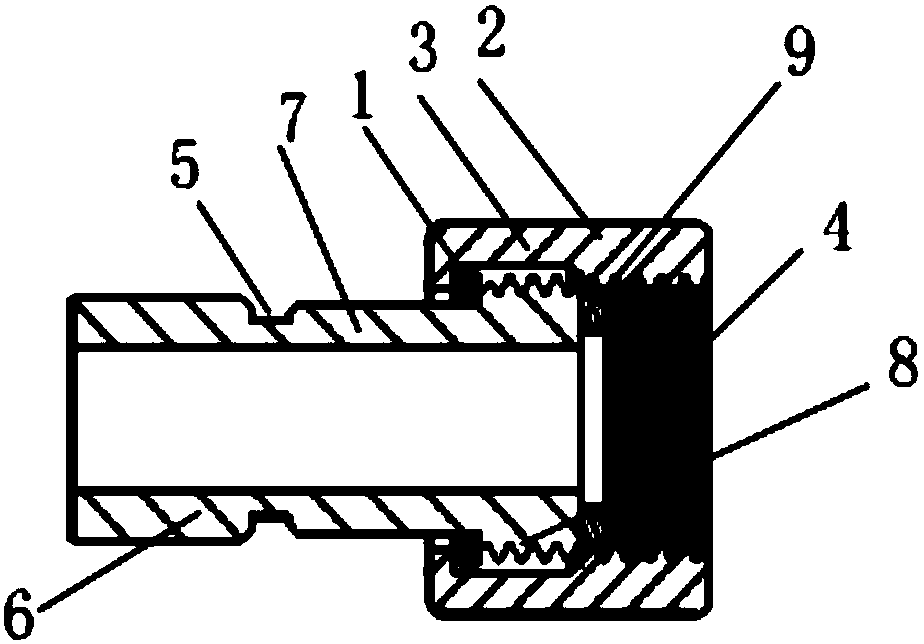

[0037] Such as Figure 1-2 As shown, the universal joint with internal and external threads of the present invention includes: a nut, a part inside the nut is an external thread coupling area, and a part is an external thread decoupling area; an external thread joint, and the external thread joint is sleeved in the nut , part of the outer side of the external thread joint is an internal thread coupling area, and another part is an internal thread decoupling area; the external thread joint can rotate in the nut along the thread and move axially under the action of the thread. A circlip is sleeved between the externally threaded joint and the nut, and the elastic circlip is used to limit the movable position between the externally threaded joint and the nut. When in use, the universal joint with internal and external threads of the present invention can be connected with other pipelines with internal threads, and can also be connected with other pipelines with external threads. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com