Simulation test engine in high-speed rotation stage

A simulation test, high-speed rotation technology, applied in the direction of engine testing, machine/structural component testing, instruments, etc., can solve the problems of process danger and low safety factor, and achieve the effect of reasonable structure, stable operation and avoiding engine explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing of description, the present invention will be further described.

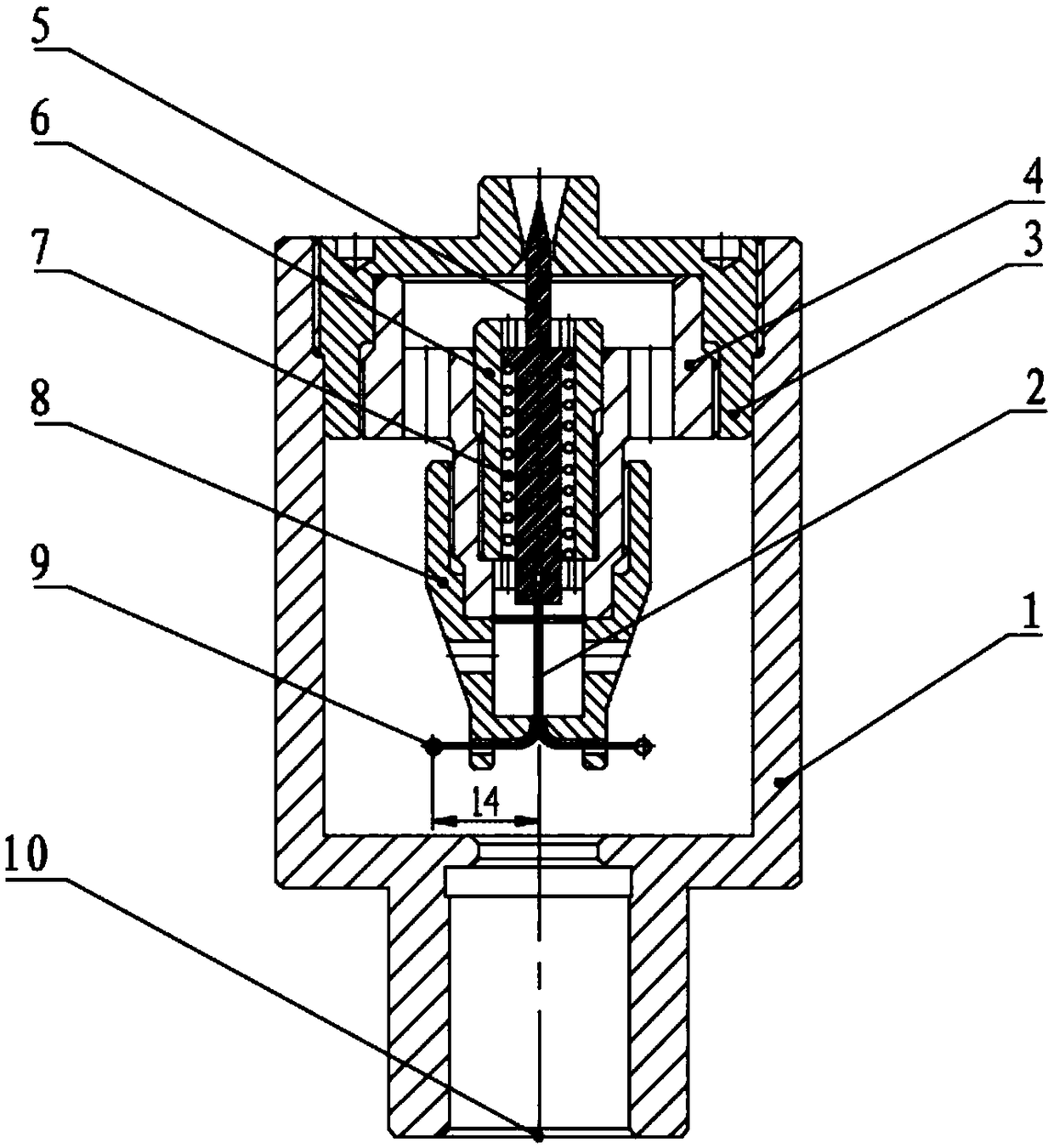

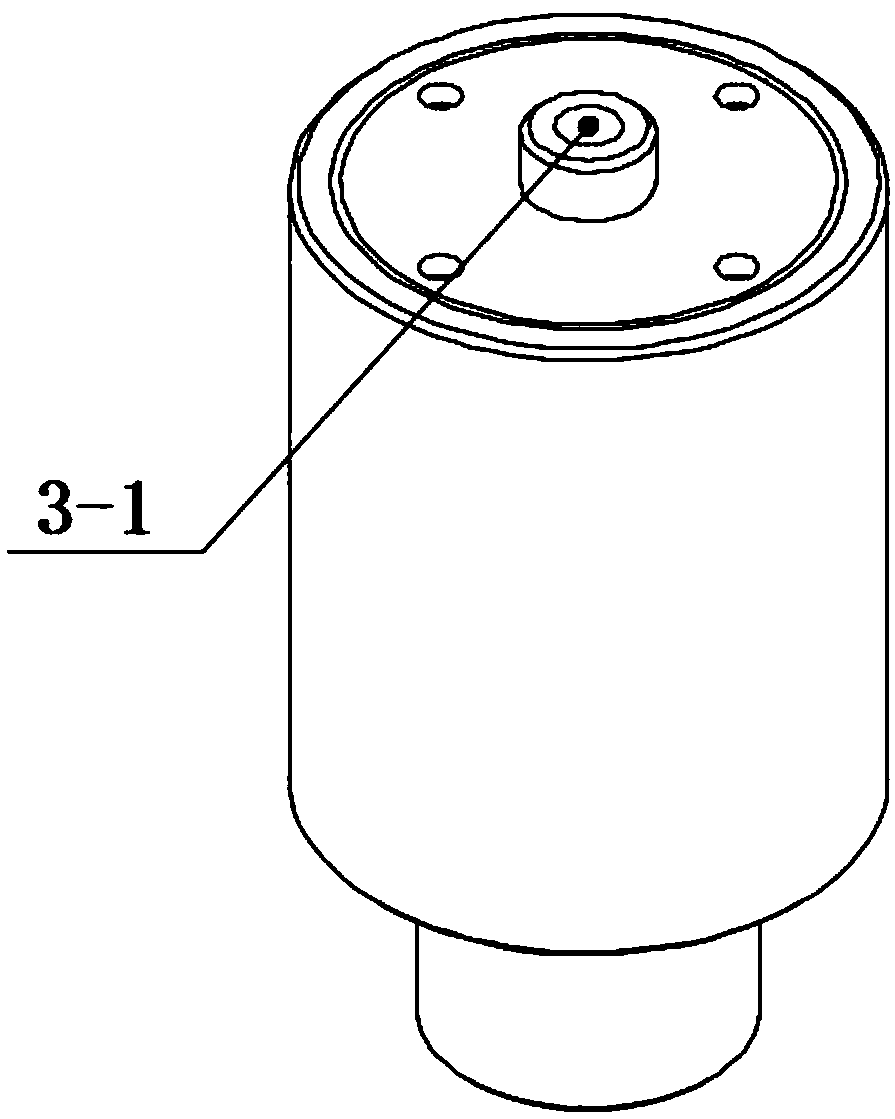

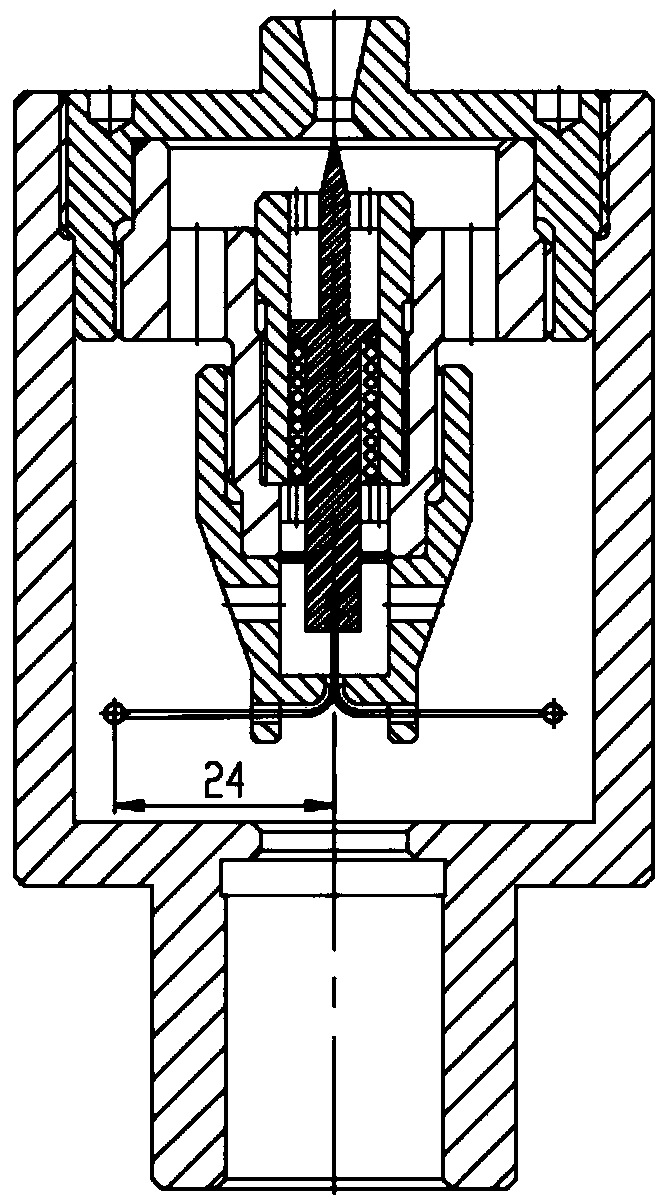

[0025] combine Figure 1-7 , a simulation test engine in a high-speed rotary table, including a test engine casing 1, two identical nylon wires 2, a blocking cover 3, a rotating shaft sleeve 4, a firing pin 5, a fixed sleeve 6, a spring 7, a rotating base 8, Two identical small balls 9, the engine casing 1 is a hollow structure with openings at both ends, the blocking cover 3 is fixed on the inner side of the upper end of the engine casing 1, and the top center of the blocking cover 3 includes a nozzle structure 3 -1 is used to simulate an engine nozzle, and the rotating shaft sleeve 4 is connected with the internal thread of the inner wall of the blocking cover 3 through an external thread. The rotating shaft sleeve 4 includes a central through hole, and the fixed sleeve 6 is sleeved In the central through hole of the rotating shaft sleeve 4, the firing pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com