Torque loading test fixture for curved surface

A tooling and curved surface technology, applied in the field of curved surface loading torsion test tooling, can solve problems such as affecting test accuracy, unreal data, test failure, etc., and achieve the effect of eliminating low matching accuracy, real data and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

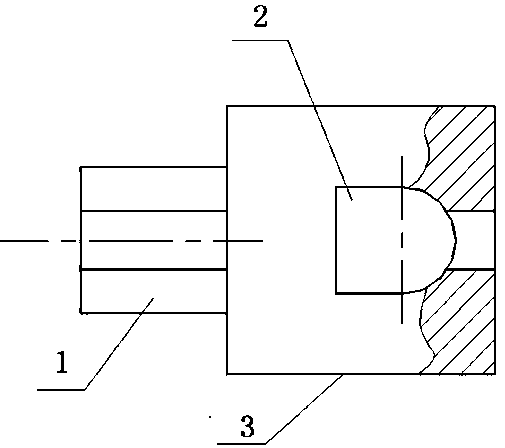

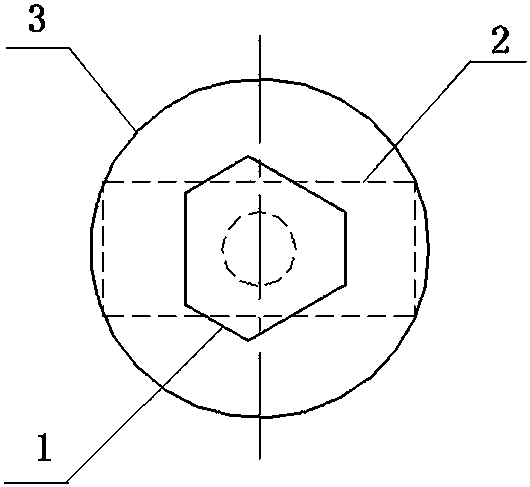

[0015] In the following, with reference to the drawings and preferred embodiments, the specific implementation, features and functions of the curved surface torsion test tool according to the present invention will be described in detail as follows.

[0016] see Figure 1 to Figure 2 , a curved torsion test tooling of the present invention includes a chuck 1, a cavity 2, and a tooling seat 3, wherein: the two ends of the tooling seat 3 are respectively provided with a chuck 1 and a tooling seat 3.

[0017] The chuck 1, cavity 2 and tooling seat 3 are integral structural parts.

[0018] The chuck 1 is a triangular prism structure.

[0019] The die cavity 2 is a die cavity conforming to the size and shape of the bearing curved surface of the part, and the end face is a plane.

[0020] The materials of the chuck 1, the cavity 2 and the tooling seat 3 are alloy steel.

[0021] When in use, the collet 1 is clamped on the torque machine, the part is put into the cavity 2, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com