An oscillation measurement method and system for simulating the vertical grain sequence of glutenite

A measurement method and measurement system technology, which are applied in the field of oscillation measurement method and system for simulating vertical grain order of glutenite, and can solve the problems of coarse gravel size, difficulty in reflecting sediment changes in real time, and difficulty or inability to provide sufficient hydrodynamic conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

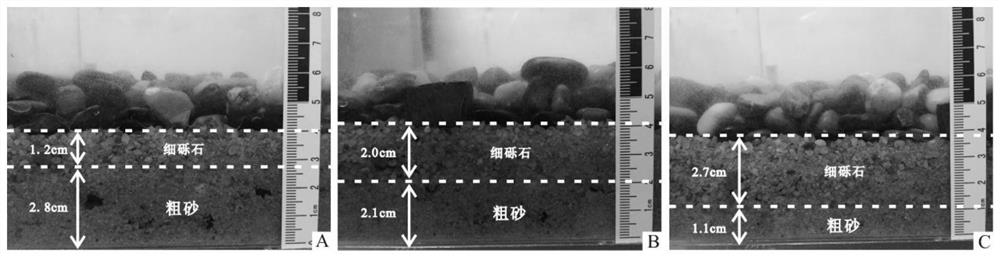

Examples

Embodiment 1

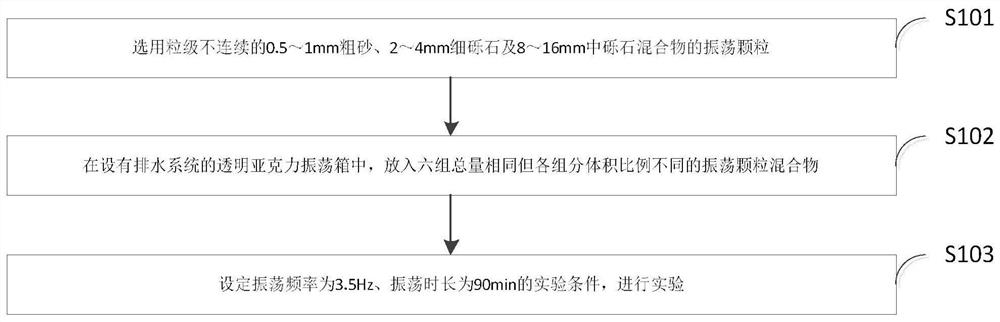

[0066] 1. Experimental device and experimental scheme

[0067] 1), simulation device and observation means

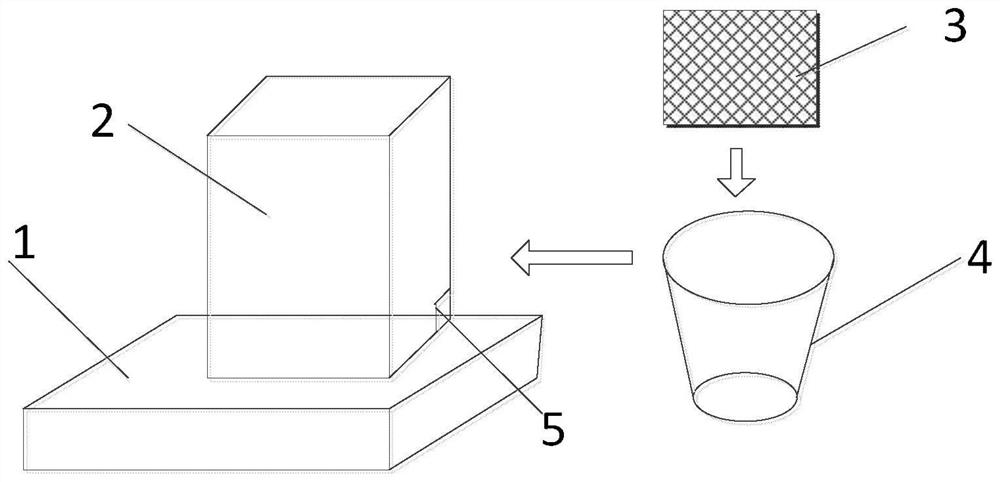

[0068] Because the gravel tank experiment is difficult to realize, the oscillation action is used to simulate the sedimentation dynamics in reality, and the sedimentation simulation device is set up accordingly, such as figure 1 shown. The device and experimental materials include four parts: oscillation box, oscillator, oscillation material and grading screen. The size of the oscillation box is 25cm×25cm×50cm. In order to simulate the effect of flowing water in reality, a water outlet with a diameter of 2cm is designed at the bottom of the side wall of the oscillation box. The oscillator adopts HY-8A multi-purpose oscillator with digital display and speed regulation, and its oscillation frequency ranges from 0 to 4.2Hz. In the experiment, sieves with apertures of 3 mesh (8mm), 5 mesh (5mm), and 16 mesh (1.25mm) were used to classify and limit the particle size range...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com