A kind of sheath embedded undercut optical cable and production method

A production method and embedded technology, which is applied in the field of optical cables, can solve the problems of inconsistent shrinkage of the sheath, inability to open skylights, difficulty in rounding the sheath, etc., and achieve the effects of easy welding operation, light weight and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

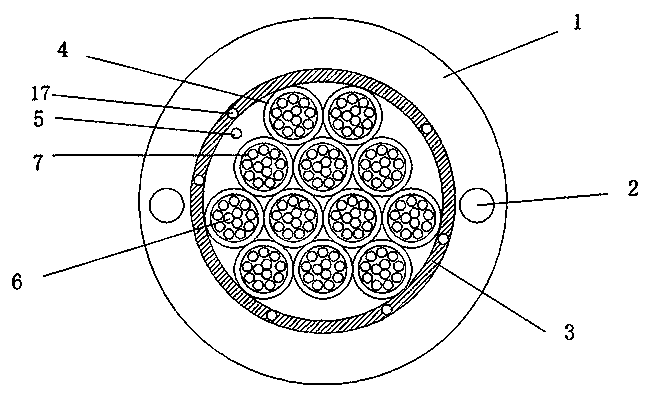

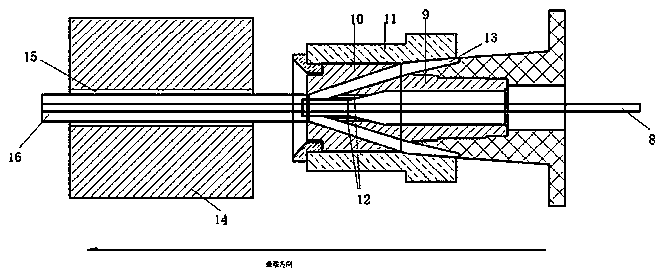

[0030] The following is based on Figure 1 to Figure 2 The specific embodiment of the present invention is further described:

[0031] see figure 1 , a kind of sheath-embedded fiber optic cable, including an optical cable 16, the optical cable 16 includes a sheath 1, a rigid reinforcement 2, a flexible water-blocking reinforcement 3, a microtube unit 4, a colored optical fiber 6, a first water-blocking element 7, The second water-blocking element 5 and the third water-blocking element 17, the exterior of the first water-blocking element 7 and the plurality of colored optical fibers 6 are wrapped with micro-pipe subunits 4, a plurality of micro-pipe sub-units 4 and the second water-blocking element 5 Twisted with each other and exist in the center of the optical cable, the outside is evenly wrapped with mutually twisted flexible water-blocking reinforcement 3 and the third water-blocking element 17 to form a cable core; the outside of the cable core 8 is wrapped with a sheath ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com