A kind of electrochromic device and preparation method thereof

A technology of electrochromic devices and electrochromic layers, applied in the direction of instruments, nonlinear optics, optics, etc., can solve problems such as easy generation of pinholes or impurities, low ion conductivity, damage to device life, etc., to achieve easy operation, The preparation technology is mature and the effect of reducing leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of the above-mentioned electrochromic device includes the following steps: sequentially depositing an electrochromic layer, an electrolyte layer, an ion storage layer and a second transparent conductive layer on the substrate deposited with the first transparent conductive layer, to obtain the obtained electrochromic device. Wherein the electrochromic layer is deposited on the first transparent conductive layer.

[0040] The electrolyte layer is obtained by sputtering deposition, plasma enhanced chemical vapor deposition, diffusion, ion implantation or epitaxy.

[0041] The present invention is further described below in conjunction with example.

example 1

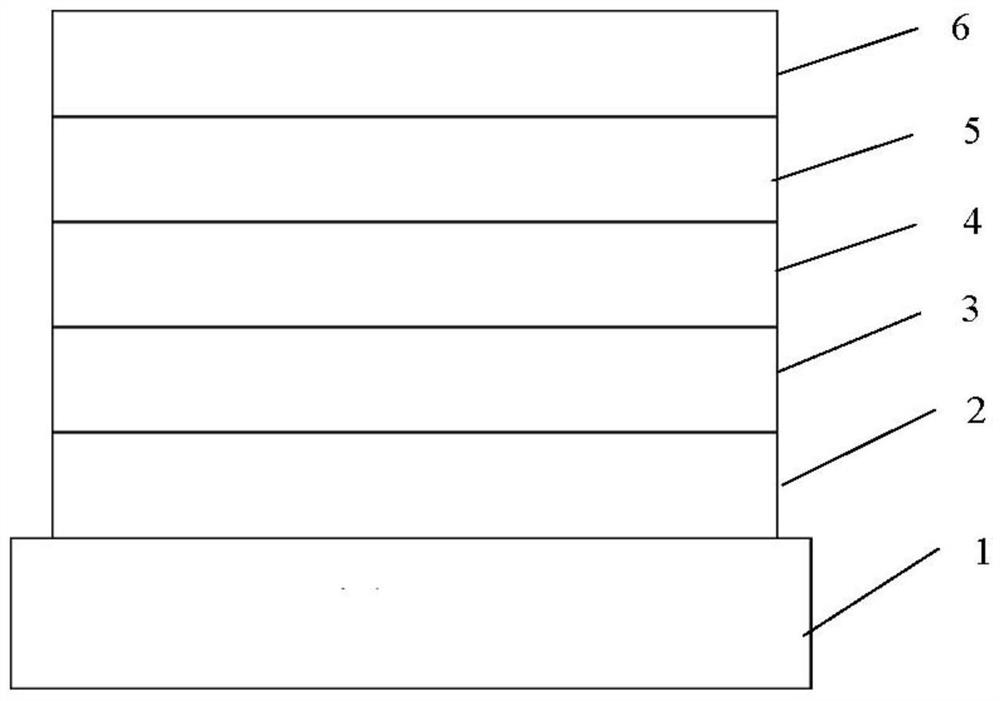

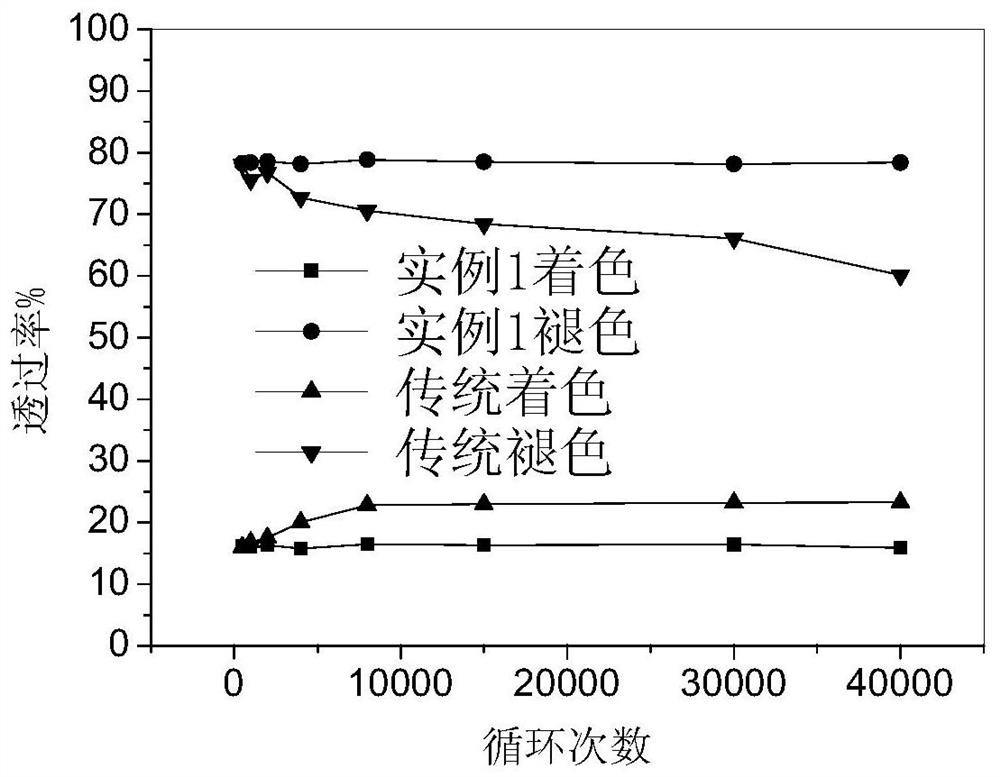

[0043] Such as figure 1 As shown, the example of the present invention provides an electrochromic device, and the electrochromic device comprises a substrate 1 and a first transparent conductive layer 2 deposited on the substrate 1 in sequence, an electrochromic layer 3, an electrolyte Layer 4, ion storage layer 5 and second transparent conductive layer 6; the thickness of the substrate 1 is 2mm; the second transparent conductive layer 2 and the second transparent conductive layer 6 are tin-doped indium oxide (ITO) thin films , its surface resistance is 30Ω / cm 2 , a thickness of 300nm; the electrochromic layer 3 is a tungsten oxide (WO3) film with a thickness of 300nm, the ion storage layer 5 is a nickel-tungsten oxide film with a thickness of 200nm; the electrolyte layer is a PN junction film, It is composed of an N-type semiconductor doped region and a P-type semiconductor doped region; the thickness of the electrolyte layer 4 is 10nm, and its transmittance in the visible l...

example 2

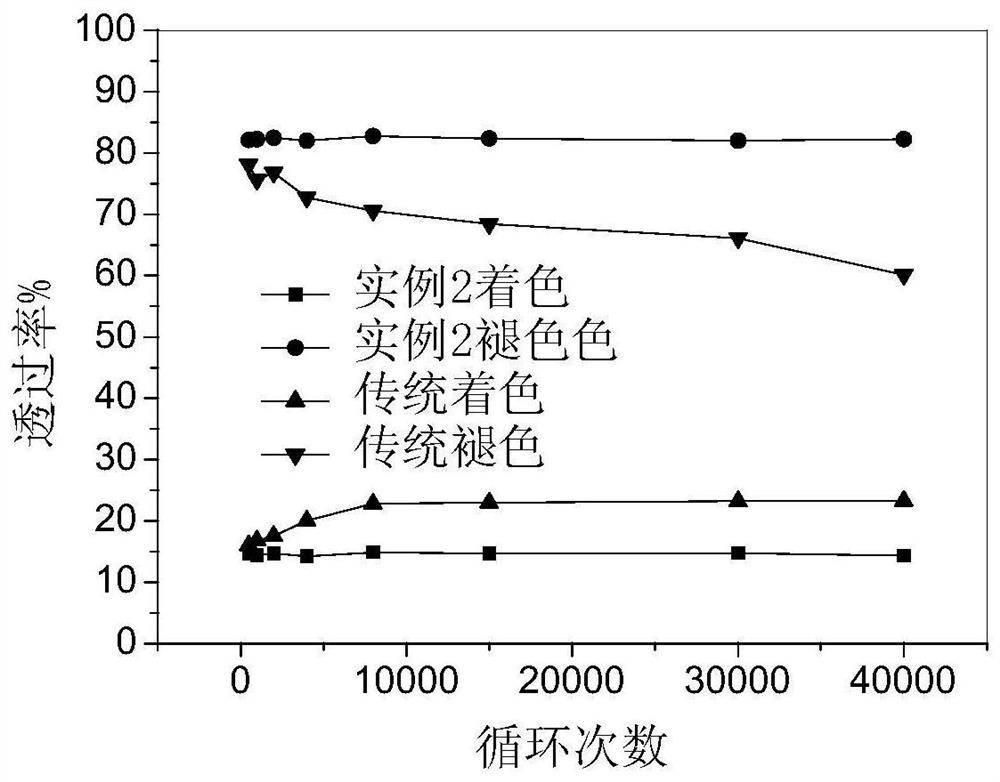

[0054] Such as figure 1 As shown, the example of the present invention provides an electrochromic device, and the electrochromic device comprises a substrate 1 and a first transparent conductive layer 2 deposited on the substrate 1 in sequence, an electrochromic layer 3, an electrolyte Layer 4, ion storage layer 5 and second transparent conductive layer 6; the thickness of the substrate 1 is 2mm; the first transparent conductive layer 2 and the second transparent conductive layer 6 are fluorine-doped tin oxide (FTO) films , its surface resistance is 30Ω / cm 2 , with a thickness of 300nm; the electrochromic layer 3 is a tungsten oxide film, and the ion storage layer 5 is a nickel-tungsten oxide film; the electrolyte layer is a PN junction film, which consists of an N-type semiconductor doped region and a Consists of a P-type semiconductor doped region; the thickness of the electrolyte layer 4 is 100nm, and its transmittance in the visible light range is greater than 80%; the el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com