field flow separation device

A field flow separation and side separation technology, which is applied in wet separation, solid separation, measurement devices, etc., can solve the problems of long time and poor efficiency, and achieve the effect of realizing analysis efficiency, suppressing device structure and increasing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

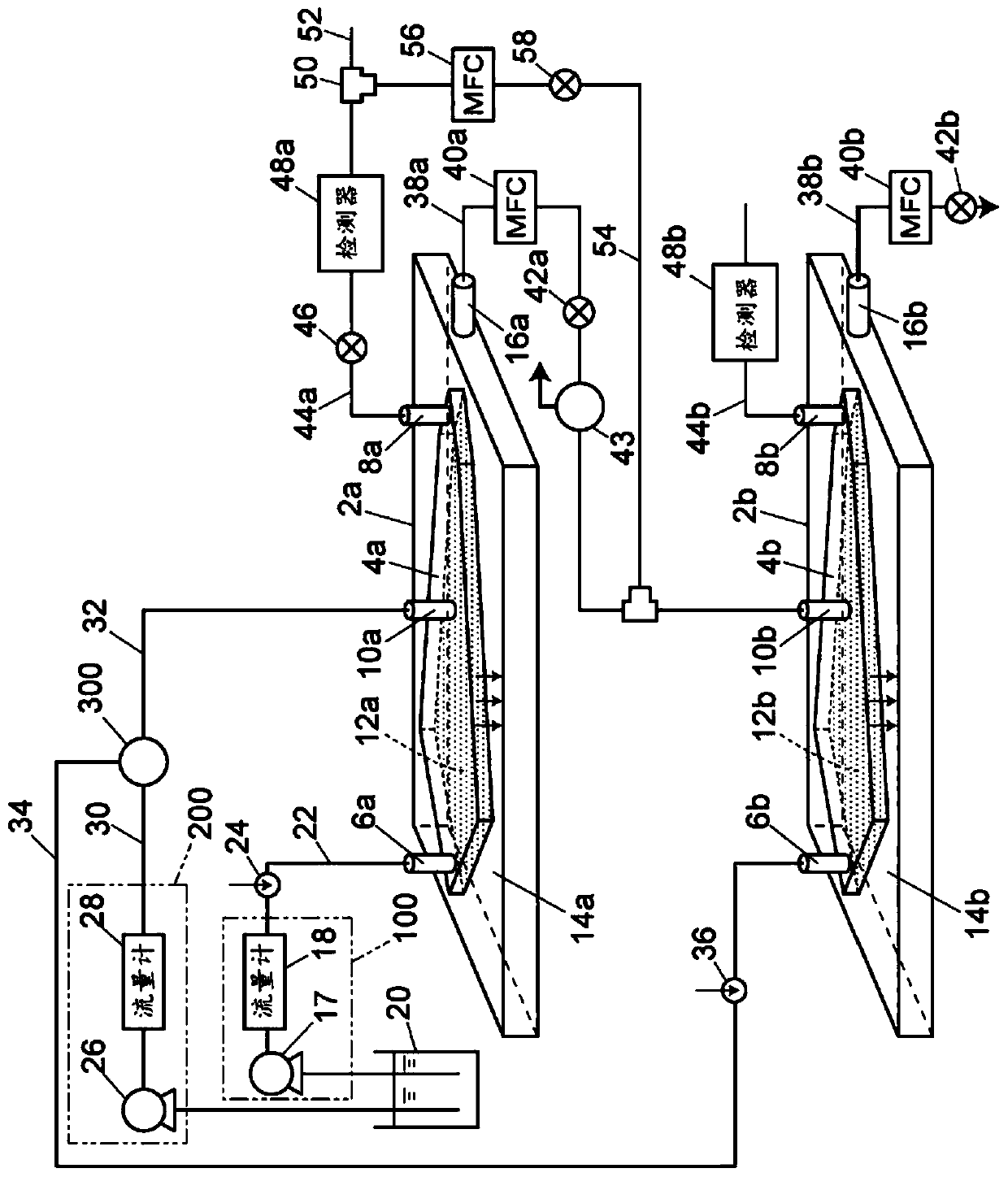

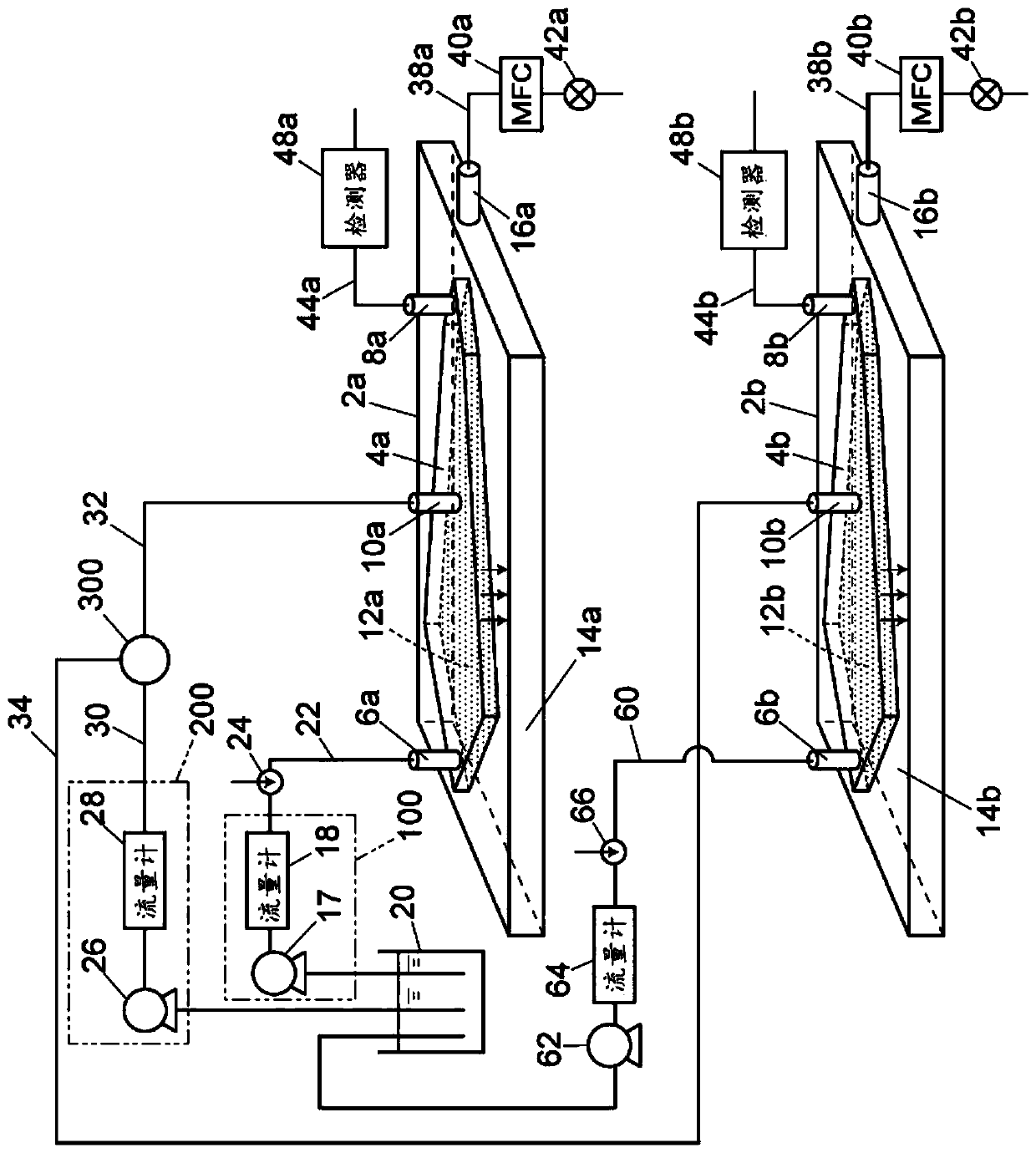

[0026] Hereinafter, an embodiment of the field flow separation device will be described using the drawings.

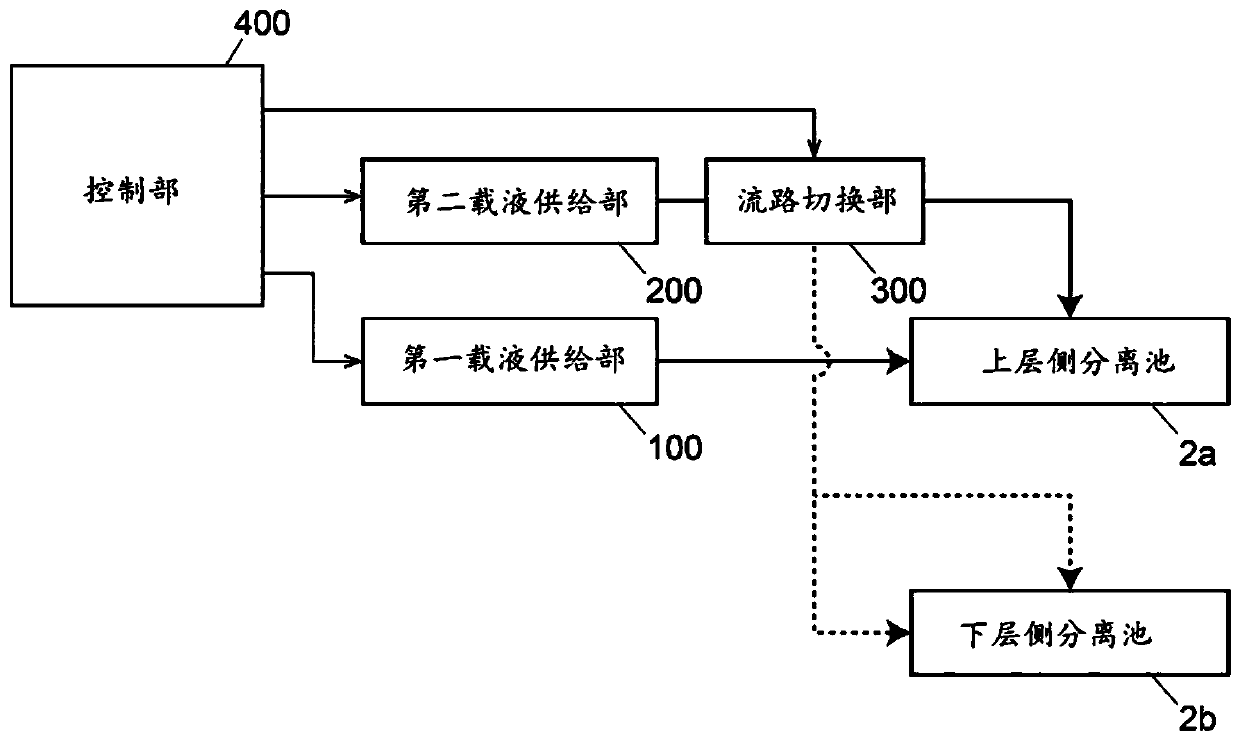

[0027] use figure 1 The schematic configuration of the field flow separation device of this embodiment will be described.

[0028] The field flow separation device of this embodiment includes an upper separation cell 2a, a lower separation cell 2b, a first carrier liquid supply unit 100, a second carrier liquid supply unit 200, a flow path switching unit 300, and a control unit 400. The upper separation tank 2a and the lower separation tank 2b form a pair of separation tanks. The field flow separation device is provided with a separation tank group consisting of a plurality of separation tanks including at least these separation tank pairs 2a and 2b.

[0029] although figure 1 Not shown in the figure, but both the upper separation cell 2a and the lower separation cell 2b are equipped with: a separation channel for separating the sample; an inlet port for introducing the carr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com