Guide wheel device capable of preventing sudden changing and reversing, sorting trolley and crossed belt sorting machine

A technology of cross-belt sorting and sorting trolleys, which is applied to sorting, conveyors, mechanical conveyors, etc., can solve the problems of reduced service life, increased noise, and huge speed changes, so as to avoid vibration shock and noise, The effect of increasing the service life and releasing the collision energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The application will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain related inventions, rather than to limit the invention. It should also be noted that, for ease of description, only parts related to the invention are shown in the drawings.

[0036] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present application will be described in detail below with reference to the accompanying drawings and embodiments.

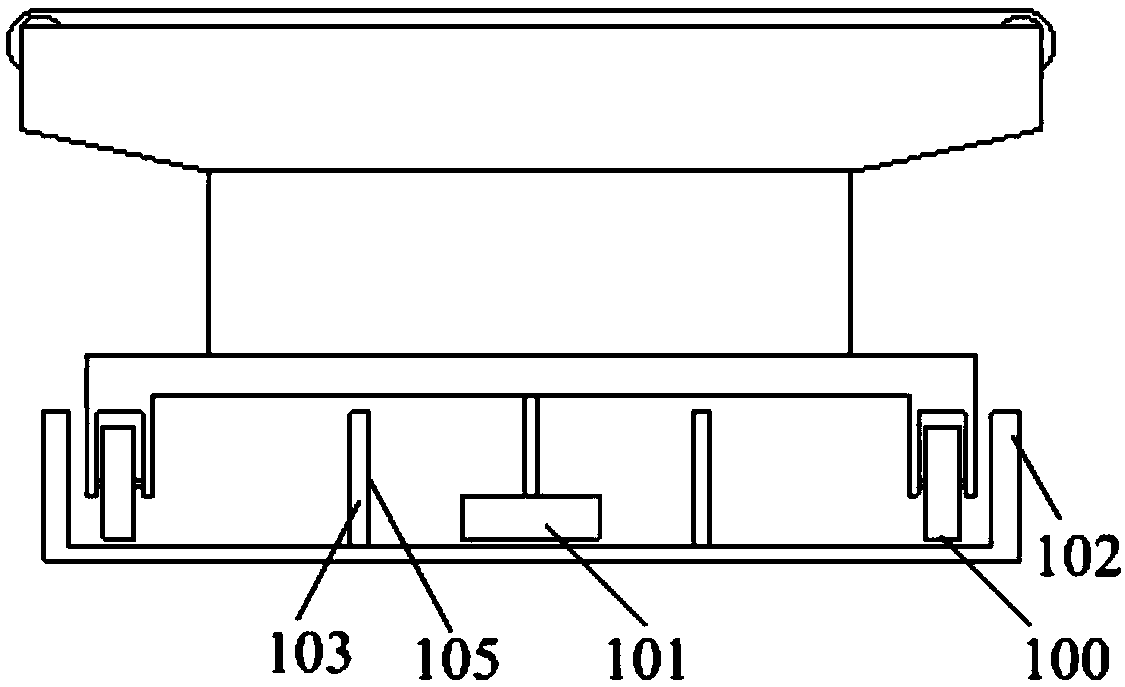

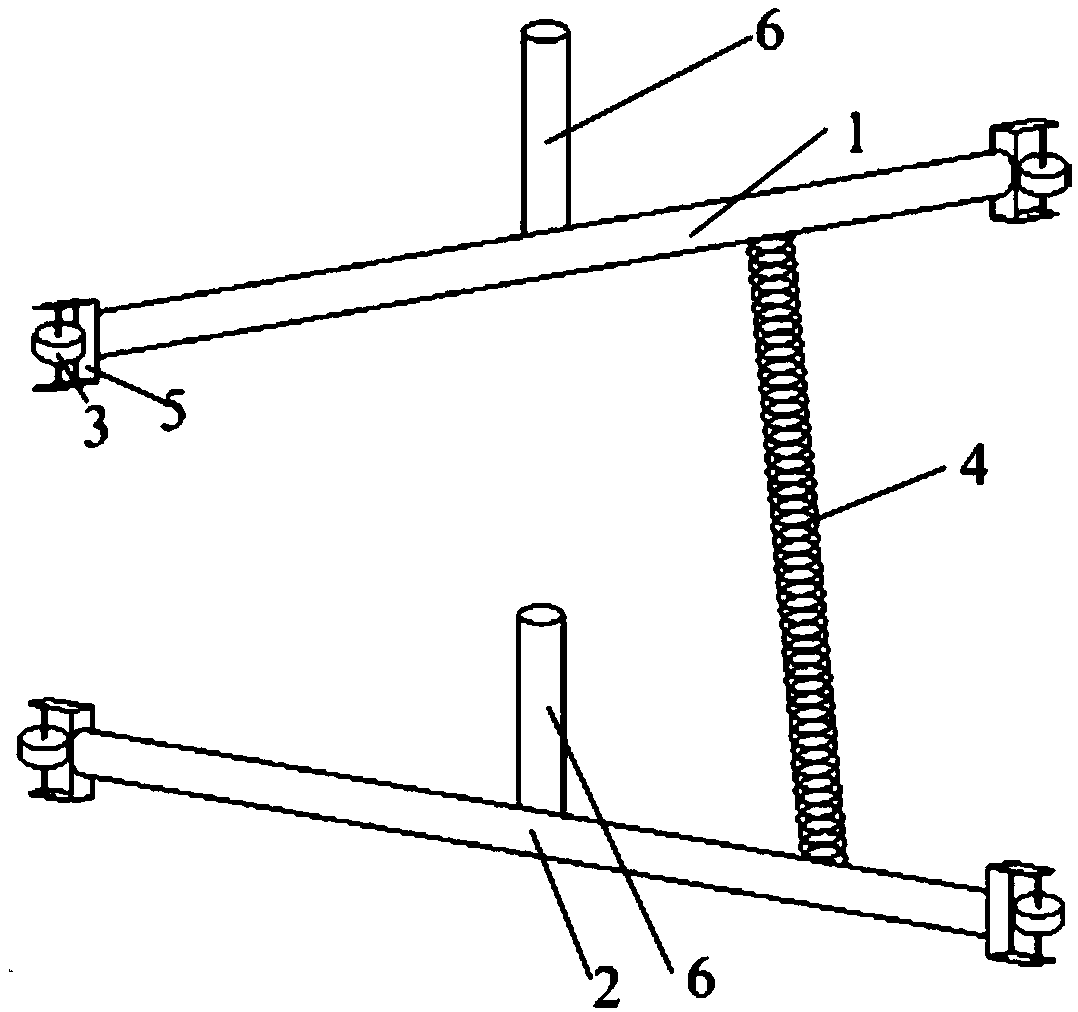

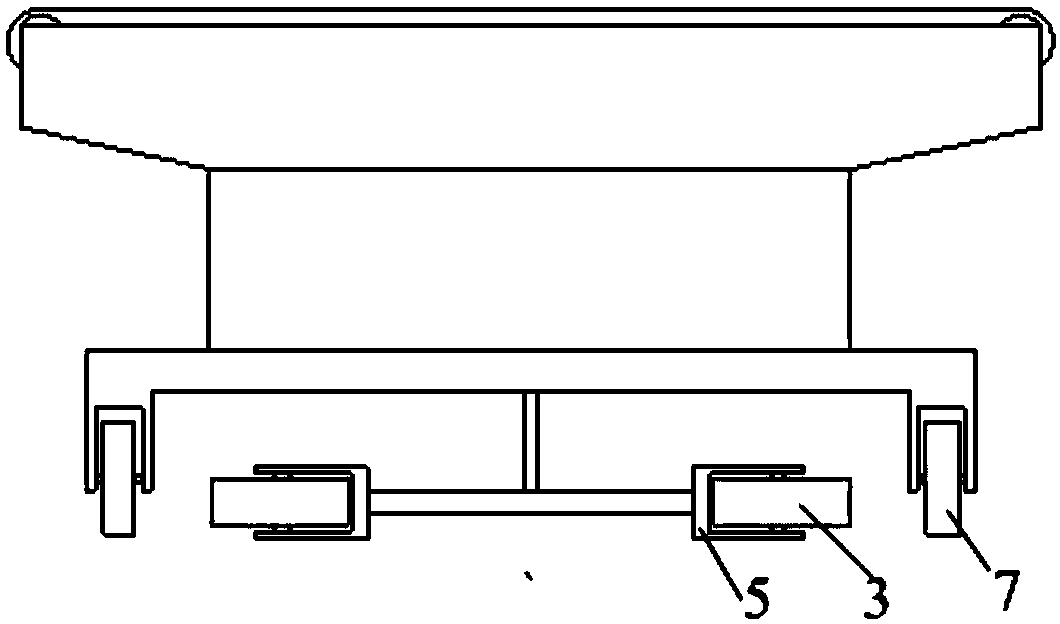

[0037] Such as figure 2 As shown, the embodiment of the present invention provides a sudden change prevention guide wheel device, including: a first connecting rod 1 and a second connecting rod 2 for movably connecting with the vehicle floor, the first connecting rod 1 and the second connecting r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com