Combined prefabricated bridge pier connection structure and its construction method

A technology for connecting structures and construction methods, applied in bridges, bridge construction, bridge parts, etc., can solve problems such as uneven distribution of stress and strain at joints, poor mechanical and seismic performance of piers, and weak segmental connections of prefabricated piers. Achieve the effect of stable and reliable overall mechanical performance, short construction period and improving overall reinforcement ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

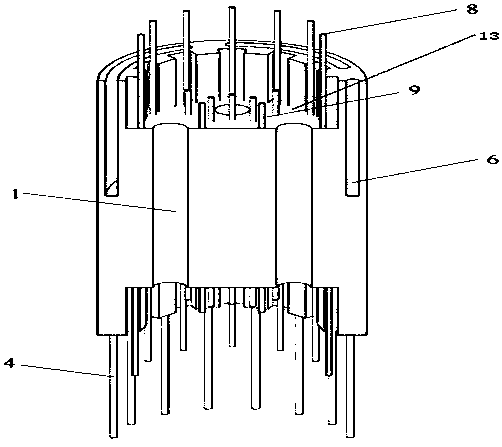

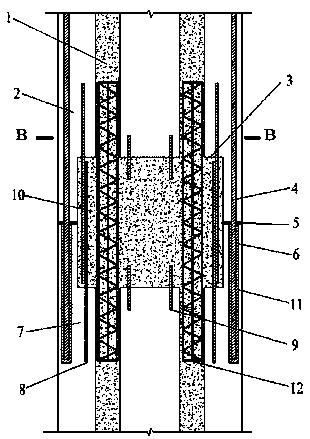

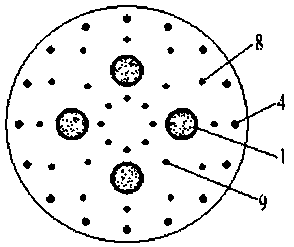

[0016] refer to figure 1 ~ 4. A combined prefabricated bridge pier connection structure and its construction method. The connection structure is used to connect prefabricated sections of prefabricated bridge piers; the top of the prefabricated section is provided with a number of staggered planting slots 6 and longitudinal reinforcement (this Not shown in the embodiment), the longitudinal reinforcement protrudes from the bottom of the prefabricated segmental pier and is divided into anchoring reinforcement 4, and wet joint cavities 13 are provided at both ends of the prefabricated segment. Preferably, the cavity 13 is arranged in the shape of a circular gear at the center of the section at both ends of the prefabricated segment.

[0017] A number of pre-embedded connecting steel bars 8 and interface steel bars 9 are arranged in the cavity 13, and four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com