Prestressed concrete pile with recoverable steel strands and construction method

A technology of concrete piles and construction methods, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of large pulling force of recycled prestressed bars, low tensile strength of steel bars, increased engineering cost, etc. The effect of flexural bearing capacity, reduction of concrete consumption, and reduction of project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

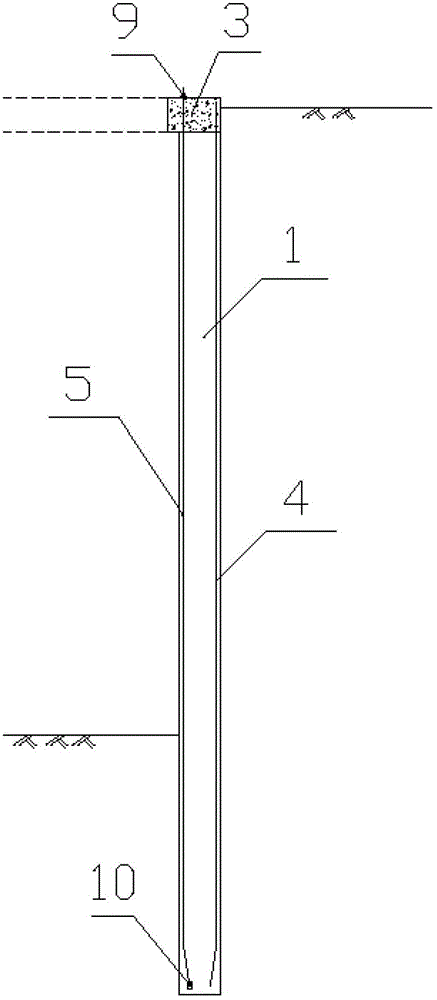

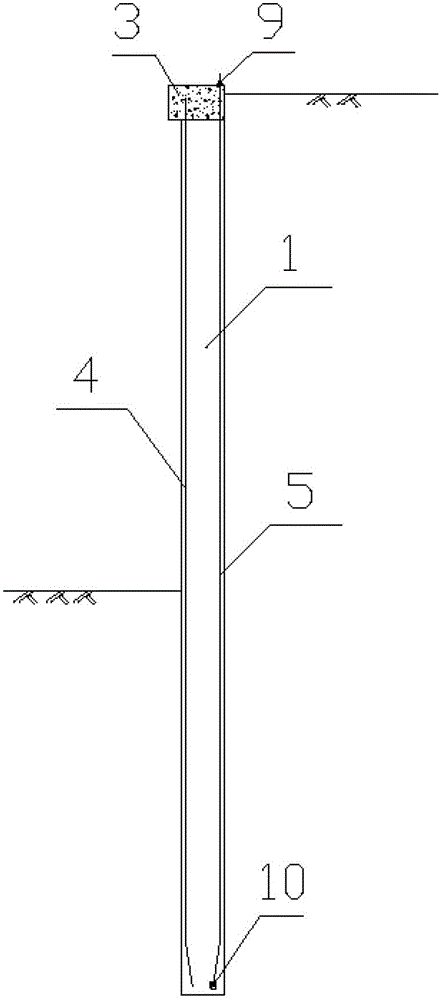

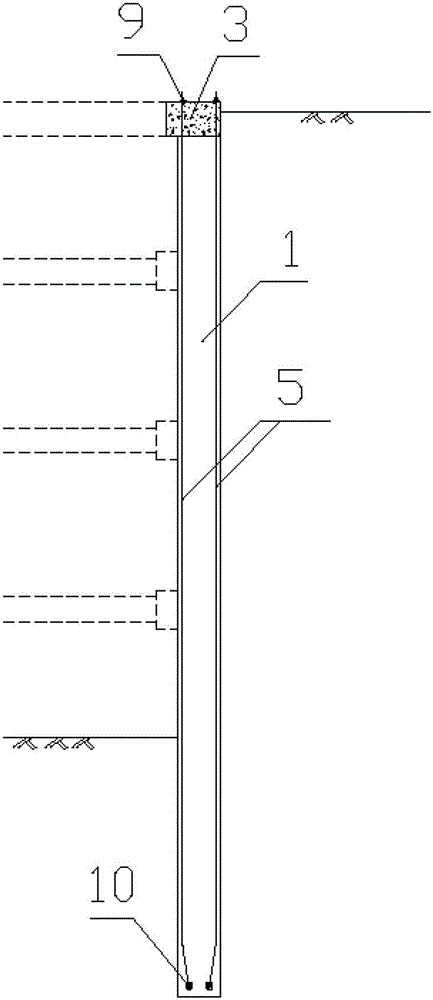

[0035] The prestressed concrete pile equipped with recyclable steel hinge wire and the construction method provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0036] Such as Figure 1-Figure 9 As shown, the prestressed concrete pile equipped with recyclable steel hinge provided by the present invention includes a concrete pile body 1, a plurality of vertical threaded steel bars 4, a plurality of single-row prestressed tendons 5, spiral tendons 6, and a plurality of outer anchors Tool 9 and a plurality of inner anchors 10; wherein the concrete pile body 1 is a cylindrical concrete structure, the vertical threaded steel bar 4 and the prestressed tendon 5 are all vertical stress bars, and the vertical threaded steel bar 4 and the prestressed tendon 5 The quantity needs to be determined according to the force calculation; multiple vertical threaded steel bars 4 and multiple prestressed bars 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com