A construction method for enhancing the overall mechanical performance of PHC pipe piles

A technology of PHC pipe piles and construction methods, which is applied in the direction of sheet pile walls, foundation structure engineering, buildings, etc., can solve problems such as low construction efficiency, inclination of pile body, difficulty in guaranteeing construction quality, etc., so as to improve vertical bearing capacity and resistance The effect of horizontal load capacity, settlement and horizontal deformation reduction, and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The above-mentioned features and technical advantages of the present invention will be more clearly and easily understood by the following description of its embodiments in conjunction with the accompanying drawings.

[0031] The drawings and descriptions are merely illustrative in nature and are not intended to limit the scope of protection of the claims. Furthermore, in this specification, the same reference numerals denote the same parts.

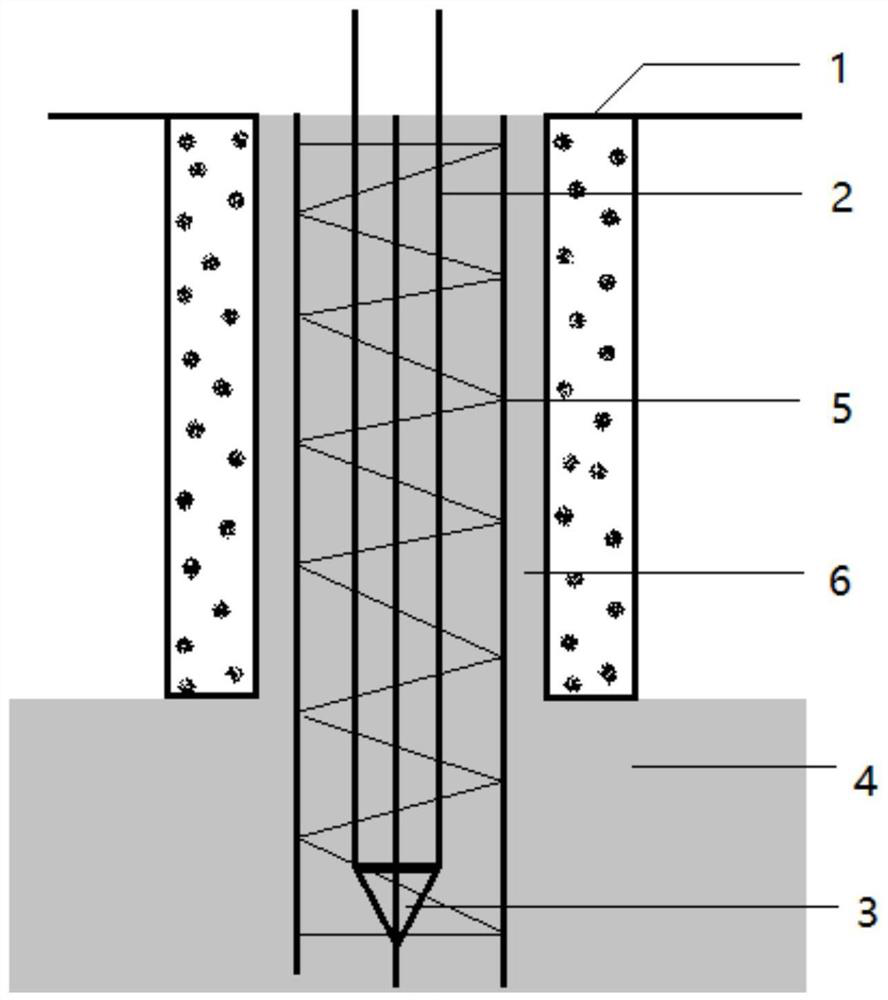

[0032] like figure 1 As shown, the structure of the new PHC pipe pile foundation is composed of: PHC pipe pile 1, drill pipe 2, rotary jet drill 3, reinforced soil 4 and reinforcement cage 5.

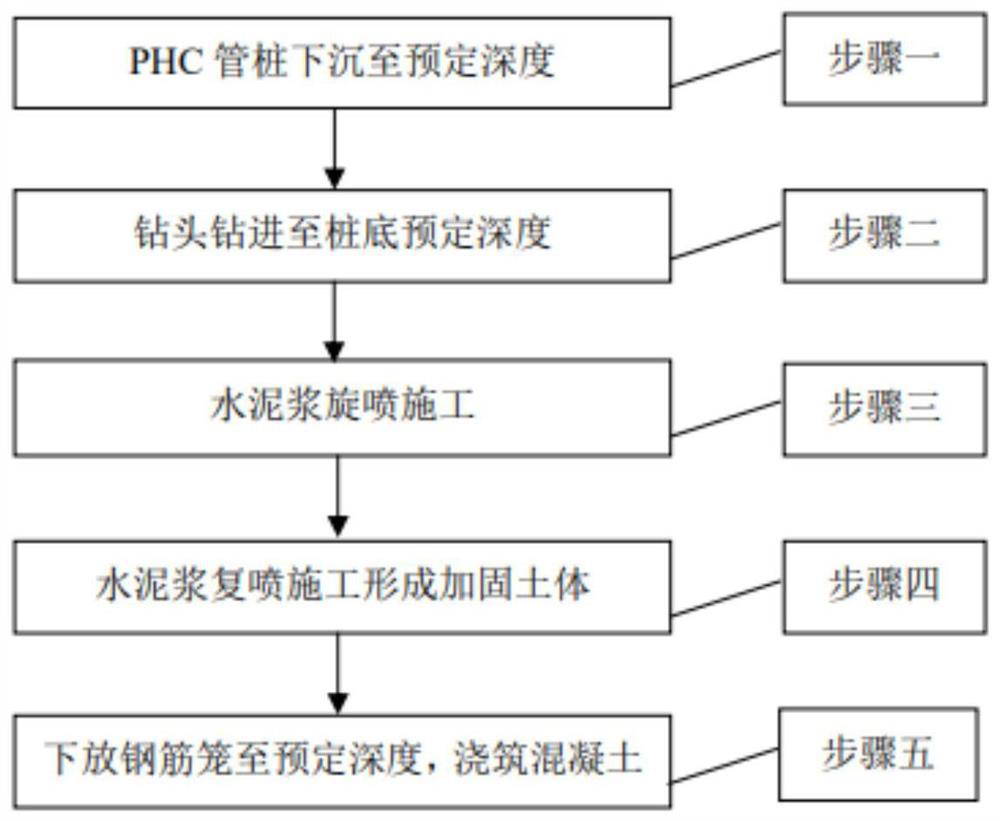

[0033] like figure 2 As shown, the construction method for enhancing the overall mechanical performance of PHC pipe piles includes the following steps:

[0034] Step 1: Select the required PHC pipe pile 1 according to the foundation load and soil conditions, and design the size of the rotary jet drill bit according to the inner diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com