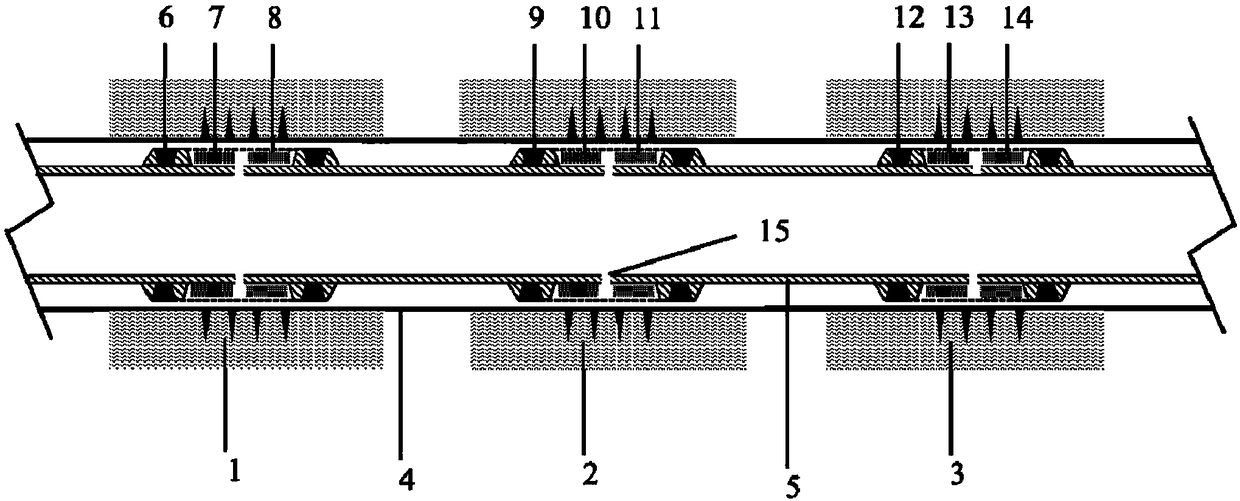

Casing perforation horizontal well liquid-producing profile testing device and testing method and production test integrated pipe column

A liquid production profile and testing device technology, which is applied in construction and other fields, can solve the problems of high temperature and corrosion resistance requirements for well entry equipment, high well type requirements, and high testing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described by the examples below. What needs to be explained here is that the present example is only an implementation method of the present invention for specific situations, and does not limit the present invention. Modifications, alterations and other changes are all within the protection scope of the present invention.

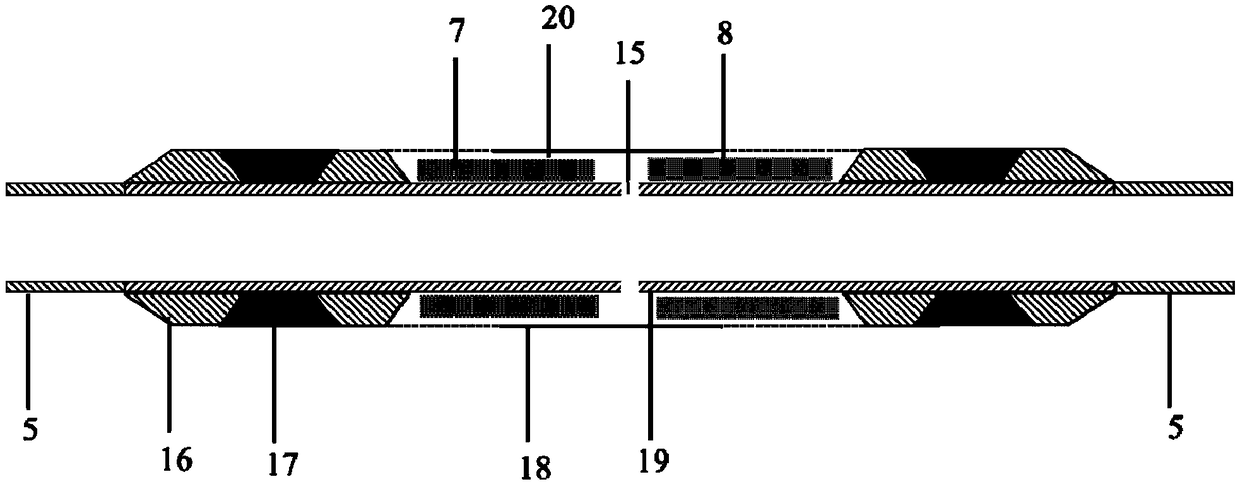

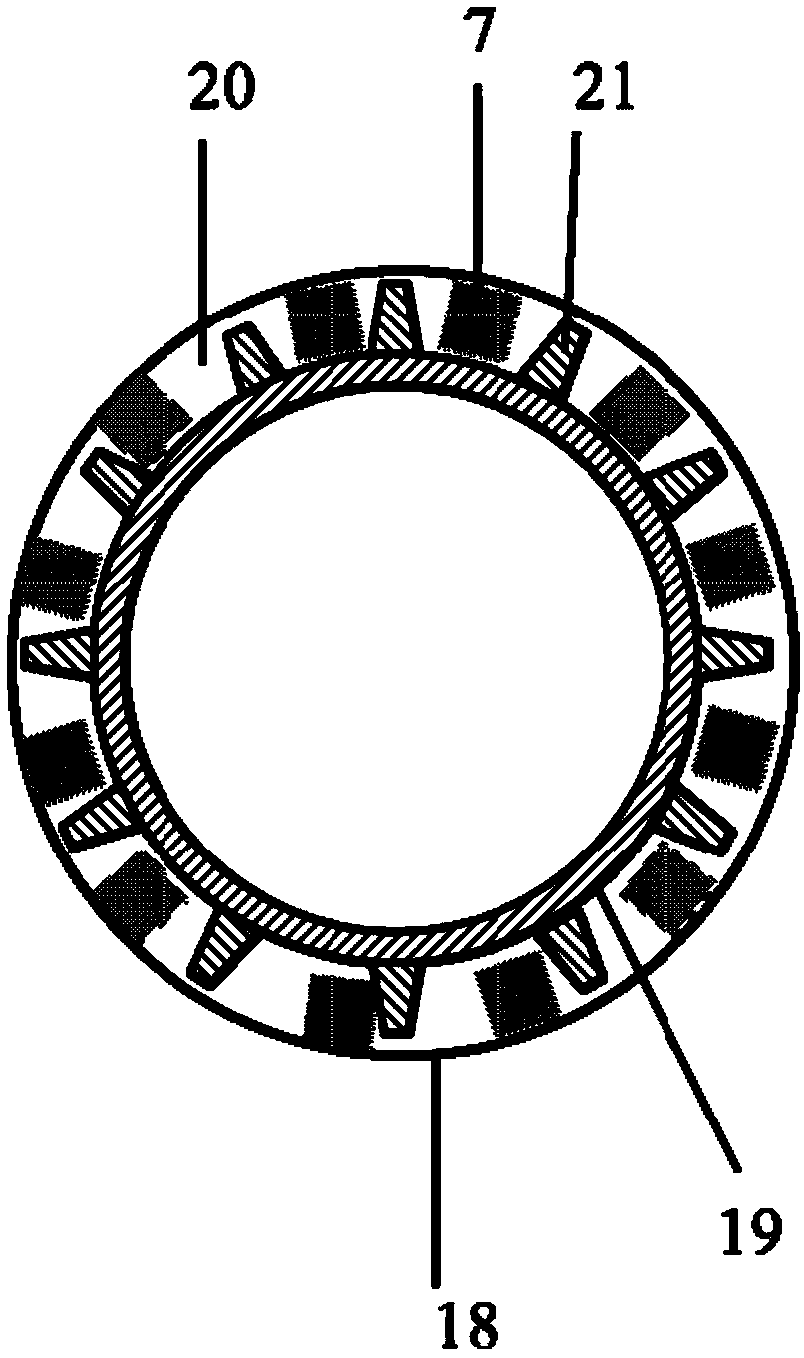

[0031] refer to figure 2, the casing perforation horizontal well fluid production profile testing device of the present invention comprises a base pipe 19, a protection pipe 18, an oil-absorbing water-absorbing swelling rubber ring 17, several water-soluble tracer carriers and several oil-soluble tracer carriers, The pipe 19 has a first liquid inlet hole 15 in its middle, and the protection pipe 18 is sleeved on the base pipe 19; both ends of the protection pipe 18 are provided with plugs for keeping the protection pipe 18 and the base pipe 19 coaxial 16, and the oil-absorbing water-absorbing expansion rubber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com