Turbine blade of gas turbine

A technology of turbine blades and gas turbines, which is applied in the direction of mechanical equipment, engine components, machines/engines, etc., can solve the problems such as the instability of turbine blades that require precision and affect the use, and achieve the effect of simple structure and easy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

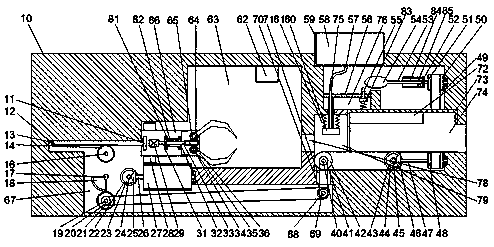

[0015] Such as figure 1As shown, a turbine blade of a gas turbine according to the present invention includes an outer frame 10, and a handle frame 66 is arranged in the outer frame 10, and a first threaded box 32 is arranged inside the handle frame 66, and the first screw box 32 is arranged inside the handle frame 66. A threaded box 32 is provided with a threaded cavity 32, the threaded cavity 32 is internally threaded with a threaded block 81, the left end wall of the first threaded box 32 is fixedly connected with the first rotating shaft 31, and the handle frame 66 is provided with There is a first motor 29, the extension of the left end of the first rotating shaft 31 is power-connected with the first motor 29, the first threaded block 81 is internally threaded with a first screw 33, and the first threaded box 32 The right side is provided with a handle cavity 65, and the handle cavity 65 is rotatably connected to the front and rear end walls to be provided with a vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com